Food production drainage systems cover Allproof’s offering of stainless steel linear drainage channels and sumps for commercial kitchens and food/beverage production facilities. This update includes the introduction of the new Modular Channel (MC) Series along with various testing and design improvements to the full range.

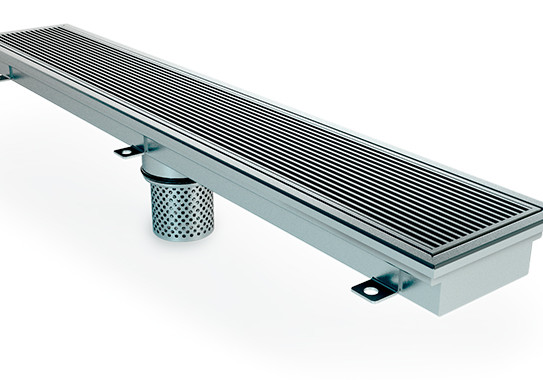

The MC Series is a modular channel drain with sump available in standard sizes creating a system that’s easy to assemble to the needs of specific projects. With a range of channels available providing various options for width, length and depth, this system provides excellent flexibility creating layouts for large complex projects. The channels come in 1m or 2m lengths allowing for transport and easy handling on site during install. Sumps are available as an end terminal or as a continuous junction for channels.

The use of joiners allows depths to increase towards the sumps for greater hydraulic performance. By selecting the 2m length channels the system accommodates runs of up to 6 metres terminating at a sump. A mirror image can then be run in the opposite direction, resulting in 10 metres between sumps. Overall system length is unlimited when using the continuous sump junction. By selecting a system constructed from standardised components it becomes easy to specify, order and install.

The Slot (SL) Series has been revised to provide standardised channel lengths improving the design and ordering process. This system is highly adaptable and can still be customised to specific layouts and projects by engaging the Allproof team through the design process.

Further updates to the range include additional slip resistance testing in accordance with AS4586 to two of the grate options providing a P classification in addition to the R classification. The Wedge Wire (WW) grate now has an R11/P2 and Slip Resistant Ladder R13/P5 providing appropriate slip resistance for all applications in fast moving kitchens and production facilities.

The CK Series outlet has now been positioned in the centre of the channel reducing the distance from the end of the channel to the outlet and making it easier for installers to set up pipework and DWV systems. Double strainer baskets and epoxy filled safety edges have been made standard across the full Food Production Drainage range.

To learn more, view Allproof's Food Production Drainage Systems brochure

Case Studies

Case Studies

Popular Products from Allproof Industries

Popular Products from Allproof Industries

Posts by Andrew Smith

Posts by Andrew Smith

Most Popular

Most Popular