Allproof has noted a trend in the popularity of open concept bathrooms. By removing a boxed shower unit a designer can dramatically open up the space. A fully tiled shower provides a seamless wet area with minimal impact on the space available which is becoming more important as space comes at a premium.

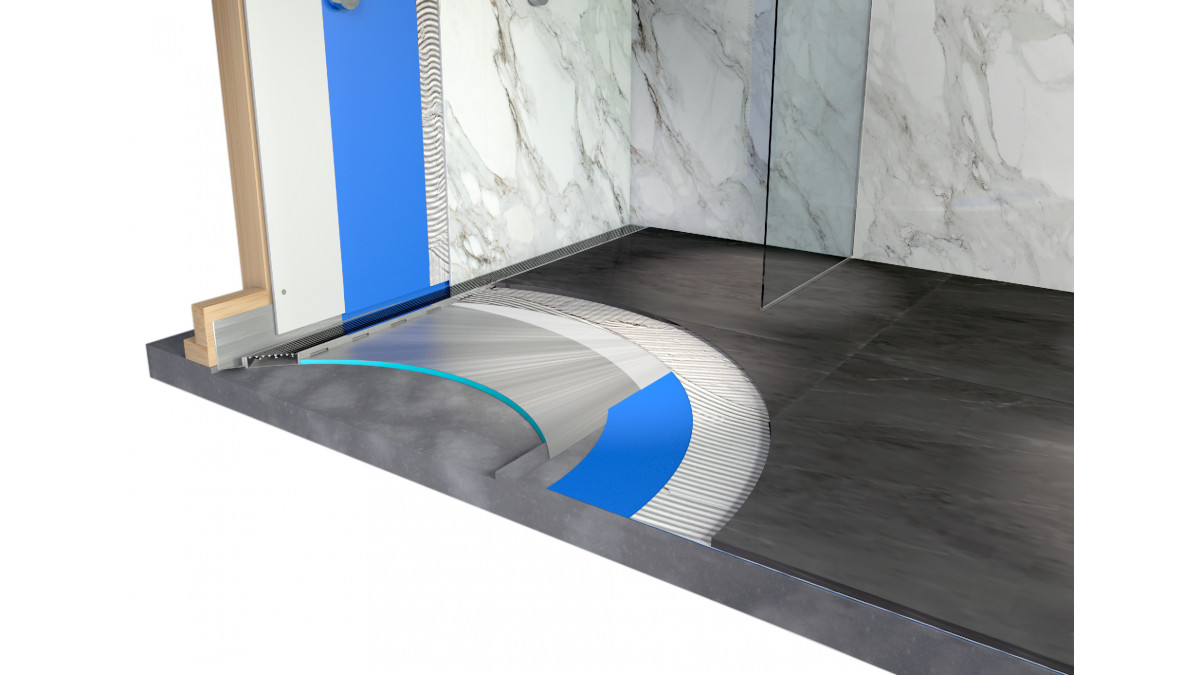

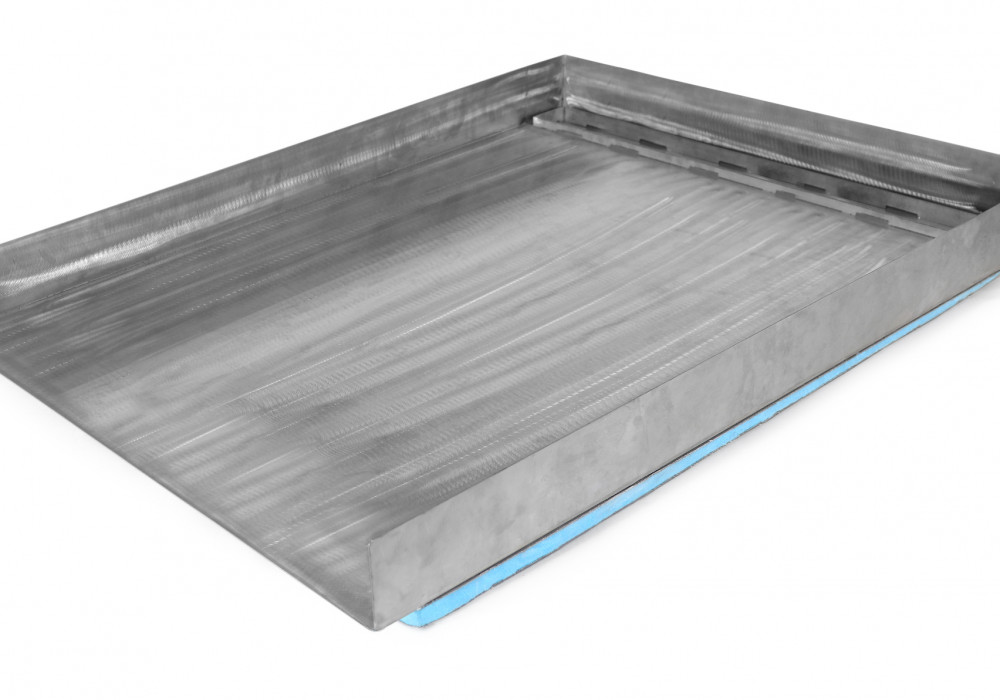

New Zealand’s wide offering of waterproof membranes combined with Allproof’s drainage systems create some excellent options to protect the structure of the building from moisture created within this area. For those who prefer the assurance of a shower tray/base being present in a shower, especially in bathrooms located in multistorey buildings, an Allproof stainless steel shower tray can be installed under the tiles creating an impermeable barrier directly under the shower.

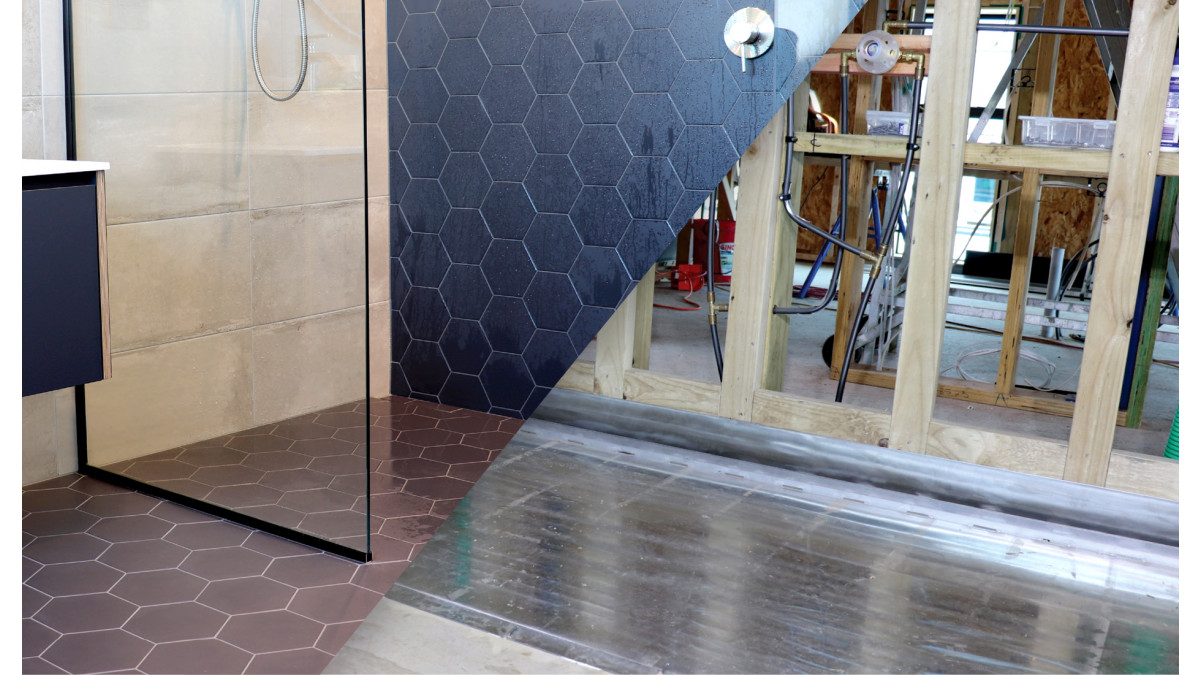

Allproof have developed a selection of stainless tray systems that are fully custom made in New Zealand specific to each project’s exact requirements, this ensures a premium solution is designed for each scenario. One project that has been supplied by Allproof’s Australian division in Melbourne is a residential renovation where there was, unfortunately, a failure in the waterproof membrane and substantial damage occurred to the flooring structure under the bathroom. The homeowner works for a prominent construction company and having encountered Allproof’s shower trays through another project decided to install one in his own home giving himself peace of mind knowing that the same issue wouldn’t occur again.

The installer designed their tray specific to their needs using Allproof’s user-friendly custom shower tray form process, accounting for fall, tile thickness and outlet location/style. While the installer completed repairs to the flooring structure, Allproof’s fabrication team manufactured the tray. Once on-site, it easily dropped into its location and was securely fixed into place following Allproof’s install guidelines. The plumbing was connected to the outlet spigot that’s fabricated to the tray, primed, fall screeded into it and waterproofed. The tiles were then applied over the top of the tray creating a discreet high performing waterproof system.

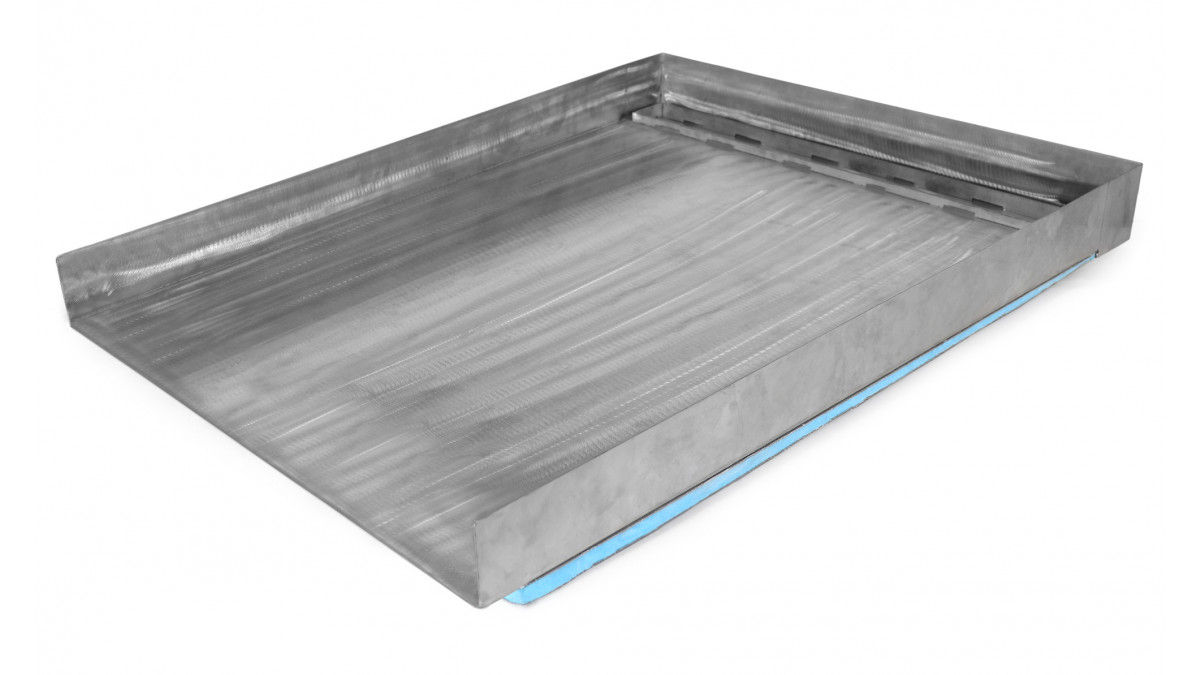

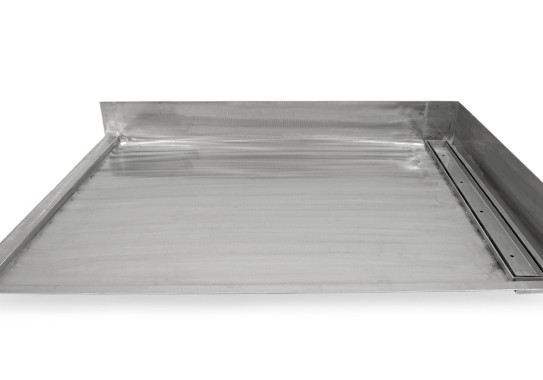

Allproof’s leading system is the Tile Over Stainless Tray which incorporates an engineered base to create the required fall towards the outlet. This system is designed to comply with all AS/NZ building standards allowing designers to select from a 1:50 fall to create a level entry shower or 1:80 for step down or hob design showers. This system removes the need to screed a fall into the tray, significantly reducing the work needed on site. The tray is rebated into the flooring system and the wall linings run down over the tray upstands. The area is then fully waterproofed onto the tray before tiles are laid over the tray and run up against the tile bar which creates a tidy line against the grate with weepage holes for sub-surface moisture trapped by the stainless tray. With a choice of point and channel grate designs, the tray can be fully tailored to the look and feel of every project. As a fully custom-made system, it provides flexibility on the shape and size of the area that needs waterproofing, removing restrictions that a shower unit or off the shelf system would have while providing a desirable aesthetic.

Case Studies

Case Studies

Popular Products from Allproof Industries

Popular Products from Allproof Industries

Posts by Andrew Smith

Posts by Andrew Smith

Most Popular

Most Popular