One of Auckland’s premier hotel and conference addresses, Cordis, opened their landmark 17 storey Pinnacle tower in late 2021, boosting the hotel's capacity to 640 rooms. This makes Cordis the largest hotel in New Zealand in terms of room count. The Pinnacle Tower was designed by New Zealand architects Jasmax, cost $170 million and provided Auckland’s central city a new level of 5-star accommodation. Behind the flashy exterior, many processes brought together the best in NZ design, construction, manufacturing and commercial plumbing.

When designing the hotel, durability and trusted systems were selected by Jasmax to give the best guaranteed lifespan of the fittings. Even as a concrete and steel structure, Jasmax were aware of the impact of building movement and the small but real risk defects can have within such a large project. A small hairline leak in waterproofing may take months if not years to become apparent and tracking the source can be complicated once the hotel is occupied.

With these points in mind, Jasmax considered the security an Allproof shower tray provides. The final aim was giving an assurance to the clients that their investment and revenue stream was well protected and in keeping with the 5-star hotel’s approach of setting “a new benchmark for modern luxury in Auckland”. From this decision, the architectural team specified the Allproof tile over shower tray system for all 235 rooms of the extension.

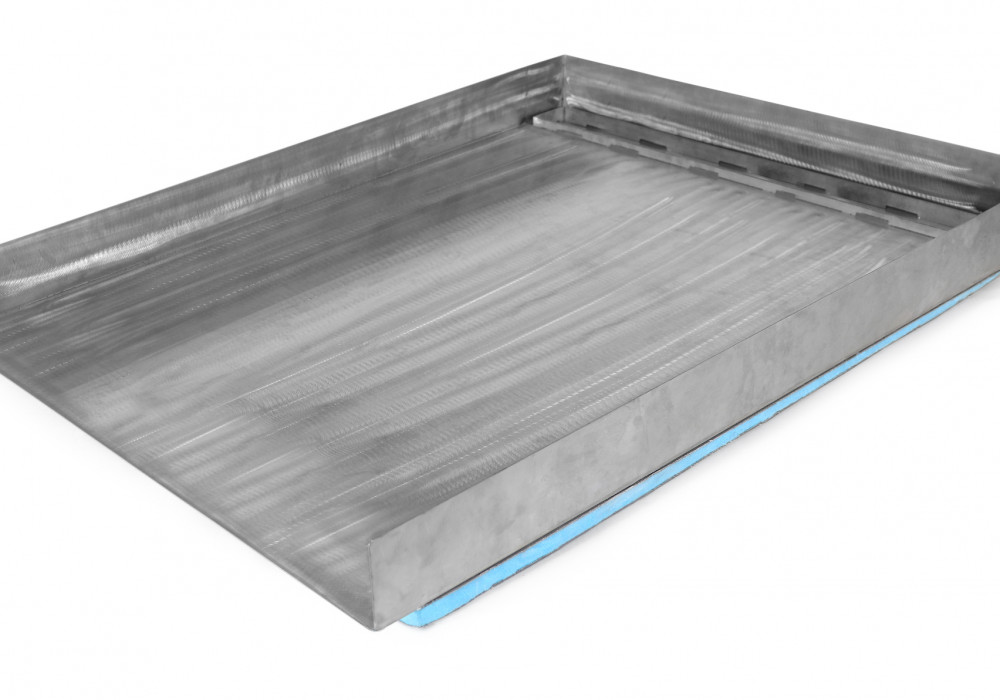

Stainless steel shower trays boast excellent waterproofing features with the impermeable layer of fully welded stainless steel falling to a flood tested channel and spigot connected to PVC waste practically eliminating any risk of failures or leaks in this high-risk area. Other options of impervious solutions such as exposed stainless or acrylic trays have limitations on durability in a high use environment and don’t often meet the interior design style demanded by a 5-star destination.

The Allproof stainless steel tray is installed over the flooring structure and below the tiles, the selected waterproofing membrane is run down the walls and lapped into the tray. The result is a fully watertight base below the tiles and behind the wall linings while providing the aesthetic of a fully tiled shower.

Allproof were engaged in the design process early on allowing time to plan the project. Allproof’s Tile Over Stainless Tray is usually custom fabricated to measure, however, given the scale of the project it became apparent another approach was required. Allproof developed 13 tray designs after several site meetings with designer, main contractor and plumber to work on solutions and specifications to meet the very tight construction timeline.

Hawkins Construction’s site manager Nick Wright’s timeline saw them scheduling a slab pour every seven days, this left no time for individual measures for each tray. In order for the other trades such as framing erectors and first fix to move ahead on their work, Allproof laser cut in-house templates of the trays to suit all room layouts. Steel framing and hobs could be formed to this template ensuring a perfect fit once the trays arrived, with no install delays. The template also included the ability to mark the outlet allowing concrete cutters to make the floor waste penetrations and plumbing services to be brought to the point of the wastes.

Allproof helped develop a sample room for sign-off from the overseas owner, Langham Hospitality Group based in Hong Kong. Through this procedure Allproof had the opportunity to refine the process and plan full scale production. Hanlon Plumbing were contracted for the installation of the plumbing systems, they expressed the importance of the schedule and deadlines.

Because of the tight timelines, other sources were investigated and found to be inferior. In order to meet the projects demands, Allproof dedicated five staff members of their 35 strong stainless fabrication team to the production of the trays with their own in-house production timeline set to meet the one on site. Their workshop comprising of, among other plant and machinery, a laser cutter, several CNC press brakes and a dedicated gluing room for the bases meant that 235 tile over shower trays were fabricated over a 9-month period and completed ahead of schedule. This is no mean feat and not a single tray was rejected, a contractor’s dream!

So, it goes to show that when the planning and selection is correct, the use of trusted suppliers and proven contractors will get the job done ahead of time, and perfectly delivered.

Case Studies

Case Studies

Popular Products from Allproof Industries

Popular Products from Allproof Industries

Posts by Andrew Smith

Posts by Andrew Smith

Most Popular

Most Popular