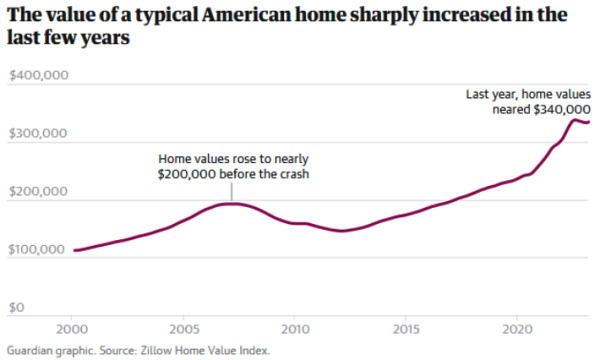

“Australian housing is increasingly unaffordable. Decades of inadequate supply coupled with high demand has driven this outcome.” — Australian Government Productivity Commission, Feb 2025

“Housing affordability is a shared problem that is getting worse across the country.” — Center for American Progress Oct 2024

The underlying problems appear to be similar:

- Housing supply being less than underlying demand

- Rising construction costs due to material and labour increases

- Challenges around consenting and land supply

These combine to make it difficult for new developments to stack up financially.

While the scale of the markets differs, the way we build houses is similar. In these three markets, the bulk of new housing are built on-site by small building companies.

Is factory-built housing the answer?

Building houses in factories is often proposed as a solution. I've watched many attempts at this fail in my 30 years in the industry. The latest being Clever Core, Fletcher Building’s recently shuttered initiative. My observations of this sector I see two fundamental issues:

- Moveability: It adds cost to make a building transportable

- Overheads: Factories entail a lot to establish and operate, a construction site costs very little

Factory-built houses must offset these costs by being more productive. Moving on-site construction methods into a building doesn’t deliver much productivity gain.

As factories need a considerable upfront investment, investors expect an economic return. This is hard to achieve when facing competitor businesses that don’t return much of a premium over wages.

Factory building also needs volume, something the New Zealand market has struggled to deliver. With our small population base, could this ever be possible?

Frame and truss manufacture demonstrates this challenge

Factory made frame and trusses are a well-established off-site manufacturing process. In spite of their near universal use in NZ, the costs for a factory frame is not that different to a site built one (though quality should be better and construction time reduced).

The processes for assembling a frame and truss in a factory are much the same as those onsite. This means they incur a similar amount of labour. Yes, framing machines and conveyors help. But not enough to offset the cost of running the factory or transporting bulky frames.

NZ frame and truss plants are small scale. They are unable to achieve real manufacturing economies available from higher levels of automation. I know, I crashed and burned trying to change this in the early 2000's.

Would component standardisation work?

One solution that I have seen that may work is standardisation at the component level. A good example of this is System 32 in cabinet making which was developed in Europe at the end of World War II to help speed up the reconstruction.

You would have all seen those lines of holes in shelf units like the one below. Those holes are 32mm apart and 37mm from the edge. Standard machines make the components. Manufacturers can then make fixtures that will fit any cabinet. It also drives the sizes of cabinets, and the sheets used to make them, and flows through into the size of kitchen appliances.

Having very standard components underneath kitchen units has not limited creativity or design. It has affected cost and competition though. You can buy a hinge from any manufacturer, and they’ll fit.

What about a “System 32” for houses?

What would happen if we designed rooms to a standard module size? Windows and doors could be standard sizes. I know from talking to manufacturers this would lower costs. Could lining, cladding and flooring sheets be manufactured in sizes that minimise waste and ease installation? Could machines make wall components for assembly on site?

Sadly, NZ probably lacks the scale to increase automation or consider modular component production. We need something like this though, where real manufacturing economies become available.

About Nick Clements

Nick won the inaugural NZIOB 2024 Digital Technology award for his work on 3D estimating in residential construction. He is a Member of the NZIQS and is vice chair of the Auckland committee.

His business, YourQS, specialises in providing cost estimating services to residential builders, architects, and homeowners for both new build and renovation projects. They have completed over 3,200 projects since launching in 2019 working for around 300 builders nationwide.

Nick is the host of the Beyond the Guesstimate podcast where he talks with interesting people ideas on how we can improve as an industry and as businesses within it.

Most Popular

Most Popular Popular Products

Popular Products