The old Fonterra storage facility was recently converted into a processing plant for NIG Nutritionals, manufacturers of goat milk products. The switch to food processing at the plant meant that floors needed to be decontaminated to meet food safety requirements.

Gilt Edge Industries Ltd provided their expertise and assistance throughout the project, from formatting the Masterspec Specification, using Gilt Edge Industries sections within the Masterspec Library, right through to overseeing the project and providing the full system warranty. They worked closely with the vinyl supplier and installers to ensure the sheet floor and wall vinyl installation would not be compromised.

“We needed to make a flat and level subfloor out of what was essentially an old, unlevelled and contaminated concrete floor,” explains Ian Williams, Commercial and Architectural Consultant at Gilt Edge Industries. “We had to decontaminate, prime and level to a high standard, to enable the flooring contractor to install the Jacobsens commercial sheet vinyl without any subfloor preparation on their part. The end result was a superb vinyl installation for the sterile environment required by NIG Nutritionals to process their foodstuffs on.”

Step One: Prep and decontaminate the floors

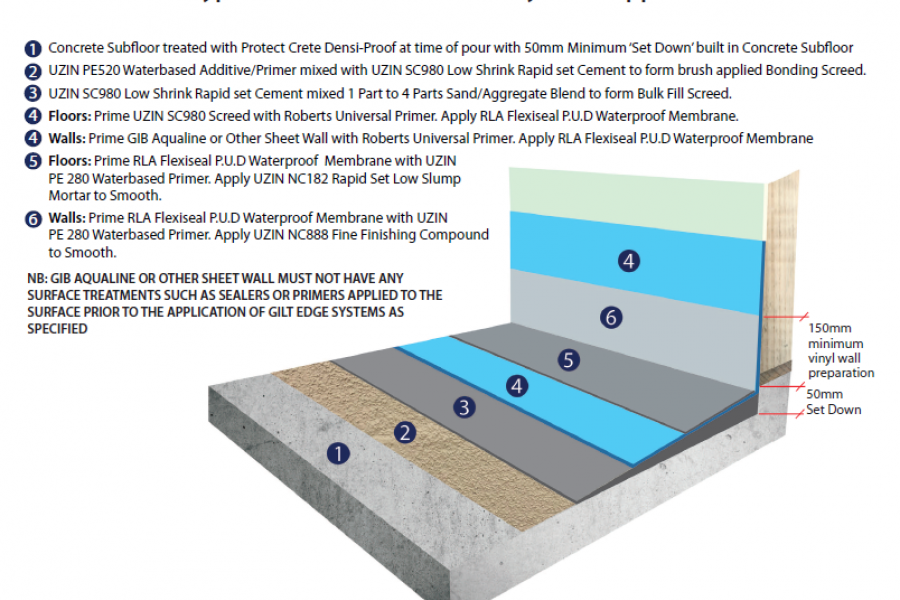

First, control joints were chased out and filled with a blend of Gilt Edge Silica Sand and UZIN PE460 2-Part Epoxy to block any possible moisture ingress.

Following this, floors were decontaminated using Protect Crete Densi Proof, a special treatment that pushes all contaminants out, while helping to harden the concrete floor and control moisture. The subfloor was then ground to remove any purged contaminants.

Step Two: Level the floors

Levelling was critical to creating a safe environment for the plant’s machinery and equipment. Gilt Edge Industries Ltd specified UZIN PE280 primer, followed by an application of UZIN NC170 Level Star. “It’s a high-quality levelling compound poured over the subfloor,” explains Ian. “It flows to gravity, so it goes really level and true.” This solution achieved an outstanding finish and impressive commercial density of 35MPa.

Step Three: Vinyl installation

UZIN KE2000s single part acrylic adhesive was used for the vinyl flooring, providing the excellent adhesion needed for the plant’s heavy contract commercial environment.

In addition to the flooring, Gilt Edge Industries Ltd specified the adhesive system for the walls for vinyl installation and supplied Gradus stair nosings for the stairwells.

The Result

The Seamless Flooring System specified by Gilt Edge Industries Ltd resulted in a cost-effective, high-standard food grade flooring environment for NIG Nutritionals. “Everyone was happy with the final result,” says Ian. “It needed to be of a high-standard, fit-for-purpose, heavy contract commercial floor. It ticked all the boxes.”

Project credits:

Flooring system: Gilt Edge Industries Ltd

Floor and walls: Tarkett commercial sheet floor and wall vinyl by Jacobsens

Flooring supplier: Carpet Court Pukekohe

Flooring contractor: Surfprep

New Products

New Products

Popular Products from Gilt Edge

Popular Products from Gilt Edge

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts