Selection of a membrane roof system involves consideration of many factors including in service usage, required robustness, membrane redundancy, environmental standards, system support, history of use, thermal insulation, condensation points and construction risks.

Within the area of construction risks, specifiers must consider what fire risks are involved with the selected system. Other construction risks include health and safety, fumes and project delays because of poor installation windows.

Membrane roof systems are specialised by nature, so it is always recommended that components/products, such as waterproofing, vapour control, insulation and substrate, that have been proven internationally are used, and that they are supplied by one supplier as a complete system. That way, the specifier has all the appropriate warranties and one point of contact for the entire system.

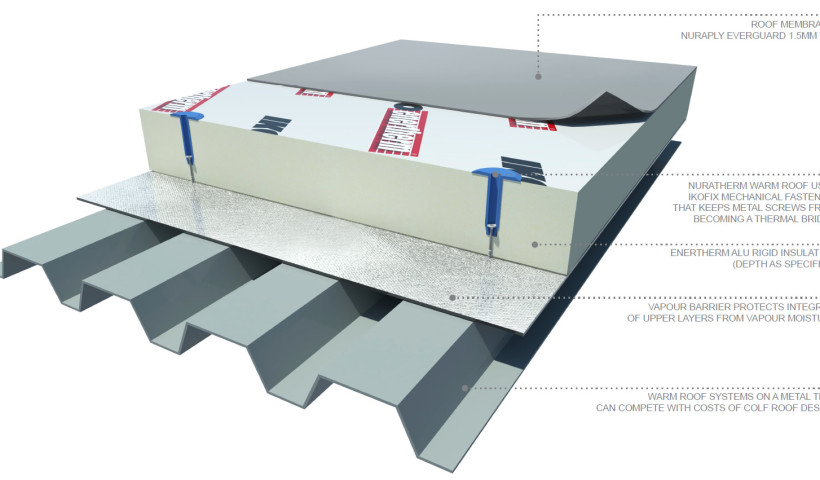

Nuralite’s leading system is the Nuratherm Warm Roof. The complete system has been tested by Warrington Fire and achieved an “in use” rating of Group Number 1-S on 0.75mm NPM900 metal tray deck.

The key to the system's success is that all the elements are designed to work together to produce a bulletproof waterproofing system with all risks fully mitigated.

Metal Tray

Nuralite recommends using steel purlins to support their NPM 900 profiled metal tray. This metal tray is mechanically screw fixed in the pan of the profile to the steel purlin. The purlins can then be spaced from 2 to 4m centres depending on wind loading. Once the metal tray is installed the building is 99% weathertight.

Primer for Metal Tray

The next component is the primer for the metal tray. This helps with the adhesion of the vapour blocker (the next component). This primer is typically water-based bitumen emulsion, or where cold climate conditions dictate, Nuralite provides the option to use a solvent-based bitumen emulsion. Care must be taken when using any solvent-based product on construction sites and they need to be fully cured before proceeding to the next stage.

Vapour Barrier

The next component to be installed is an aluminium faced vapour blocker (MVTR 5000+). This product is self-adhered and requires no hot works to install it. The installers simply remove the release film from the back of the product and apply it to the primed surface.

Insulation Layer

This stage of the roof buildup requires the installation of a rigid PIR insulation board. This has aluminium foil facings on both sides with a bulk density of 32 kg/m³.

Enertherm PIR is a high performance, closed-cell and fibre-free insulation product, with high compressive strength. The insulation has a low smoke emission rate and does not melt or drip, in short, it displays excellent fire performance characteristics. The insulation complies with NZ 2122.1-1993 for flame propagation.

The PIR insulation board is either glued with an adhesive or mechanically fixed, using a thermally broken screw fastener through to the metal tray substrate.

Membrane System

Once the insulation layer is installed, the contractor will then apply the first layer in the bitumen-based Nuraply 3PM membrane system. This 3mm thick layer is self-adhered to the rigid PIR insulation board, which means no naked flame is used for its installation.

When this base sheet layer is installed, the roof is then fully waterproof and airtight.

From this point onwards, Nuralite believes it is safe to use a gas torch for the application of the 4mm thick granulated finish cap sheet. Nuraply 3PM includes Graphite technology to resist the incipient spread of flame and to self-extinguish.

“Cap sheeting” as it is known, is carried out by highly skilled personnel who use a gas torch to heat and melt the upper surface of the base sheet and the lower surface of the cap sheet, forming a homogeneous, fully welded bond. Due to the application of the base sheet there is very little risk of any flame coming into contact with other construction materials within the building.

Case Studies

Case Studies

Popular Products from Nuralite

Popular Products from Nuralite

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts