Written by Jon Davies

Technical Sales Support and Education Manager, Pro Clima New Zealand

Building envelopes are often missing three out of four key elements. In this article I'll describe an overall theme of connectedness and describe how we can connect windows more effectively.

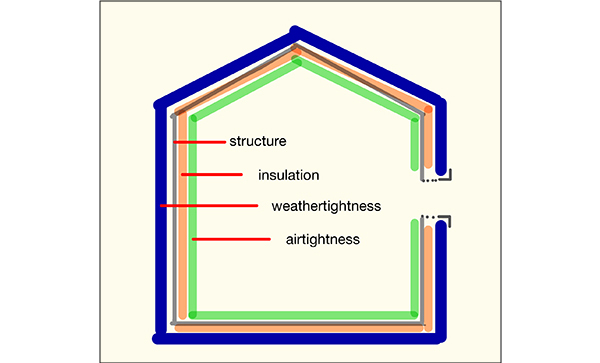

The four key layers are:

- Continuous structure

- Continuous insulation

- Continuous weathertightness

- Continuous air control

Fig 1. Fingerprint

The basic expectation of a building includes it being able to stand up unassisted, therefore we can confidently say that (new) buildings have a continuous structure — a combination of framing, maybe a floor slab, all connected together.

What we cannot say for certain is that the other three critical layers exist in continuity.

Insulation

In our experience, insulation is rarely connected at a number of junctions, including floor to wall, ceiling to wall and window to wall.

Weathertightness

Weathertightness layers such as a flexible wall and roof underlay (as the last line of defence) are rarely connected at floor to wall, wall to roof, window to wall or underfloor junctions.

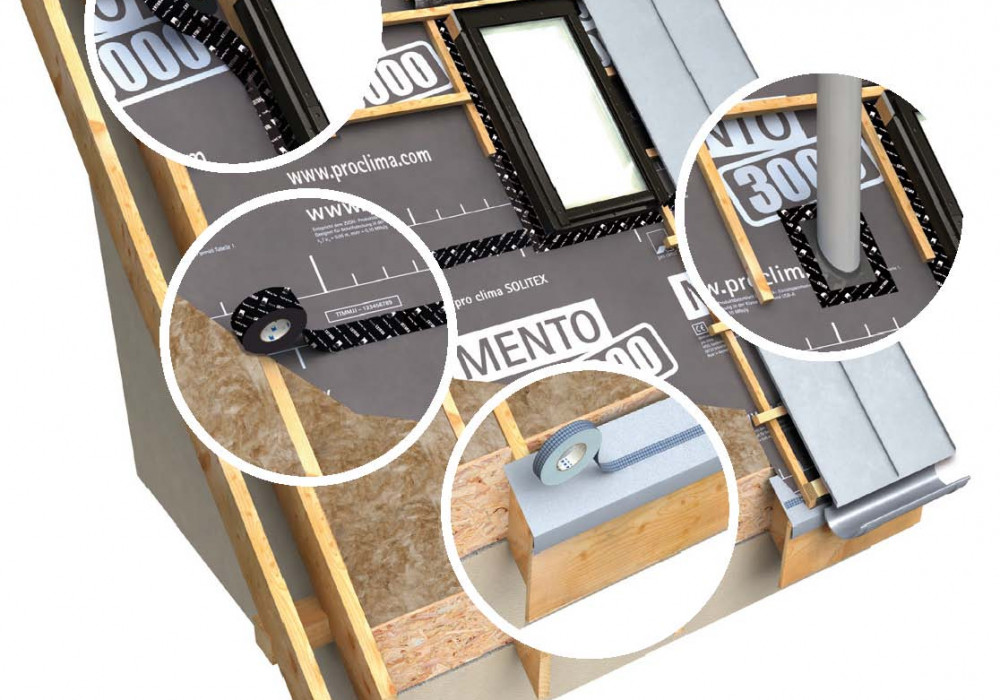

Air Control Layers

Traditionally plasterboard has been used as an air control layer which might be ok if we didn't poke holes in it to run power points, light switches, data points, extract pipes, plumbing gas and drainage pipes, not to mention windows and doors. The connection is missing for this critical 'draught stopping' element at these junctions: floor to wall, ceiling to wall, window and door seals (unit) and flooring to flooring.

Window and Door Performance

So what to do? Let's pick on one area that is 'low hanging fruit' for the performance of our buildings in general — windows and doors.

- Structural connection is relatively easy: Fix it to the building.

- Insulation should line up: The position (depth) within the wall makes the biggest difference. Aside from the fact windows are ten times weaker in thermal performance than the wall they sit in, the IGU should run in the same plane as the wall insulation and this gives lots of scope for positioning. The 'highest performance' window will still perform poorly if it is hung outside the building/insulation line. Bring windows inside.

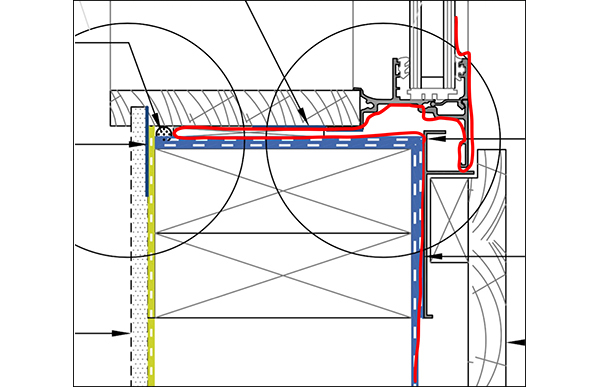

- Weathertightness layer should connect at the outside: we can't keep relying on a temporary product 'system' like PEF rod and foam to provide adequate weathertightness performance. I encourage you to pick up a pencil and draw where the weathertightness layer actually goes in a standard detail — it may surprise you to see how many corners you'll end up making as your line wriggles all the way in to the PEF rod and out again till you get the glass (see fig. 2 with red pencil line below). Compare this with the Altus 'Smartfit' window and its weathertightness connection which is in a straight line with the wall underlay. We offer multiple solutions for connecting weathertightness at the outside for all types of windows.

- The 'air control' layer (airtightness) can be connected to the inside in a very similar fashion to the external side and the additional benefit is the ability to insulate further between those two layers.

Fig 2. Red pencil

Outcome

What is the gain? Improve the performance of windows for H1, E2, E3 and B2 performance requirements.

What is the loss? Condensation. Drafts. Mould. Fear of water ingress if we bring windows inside the line of the building envelope.

Written by Jon Davies

Technical Sales Support and Education Manager, Pro Clima New Zealand

Most Popular

Most Popular Popular Products

Popular Products