Written by Richard Hollard

Specification Manager, pro clima New Zealand

2011 was a big year for New Zealand. The All Blacks hosted and won the Rugby World Cup (finally), local lasses Lorde & Lydia dominated music charts and Golf Majors, a house cost half of what they do now (but still weren’t very affordable), and the Ministry of Education released the first version of its Weathertightness Guidance document for Architects and Designers.

The Weathertightness Design requirements were put together to ensure that our track record of weathertightness remediations, which are disruptive to schools and costly for the taxpayer, become a thing of the past. If we cannot build learning environments that are safe, healthy, and durable, what penalty are we imposing on the kids trying to learn in those environments?

The MOE’s Weathertightness Guidance document (referred to as ‘the document’ from here on) was updated in 2014 with a focus on Durability. Then Version 3.0 was released in September 2020 as the ‘Weathertightness Design Requirement for School Buildings’, with as the title suggests, more focus on design aspects. Version 3.0 represented a change introducing new systems such as warm roofs. The document was revised again in September 2023 as Version 3.1, with its scope being broadened to include new school buildings and extensions and additions while excluding buildings requiring weathertightness remedial work.

In this article we look at some of the elements included from Version 3.0 of the document onwards which would be deemed ‘above code’, and discuss the whys, hows and wheres of their practical application.

Walls/cladding

The requirements step away from a reliance on sealants for weathertightness, with mechanical flashings preferred for cladding system junctions. Durability and product compatibility would be the main drivers here, as physical flashings will always be more robust and durable than a line of sealant which can be more installer-dependant and may have more maintenance required.

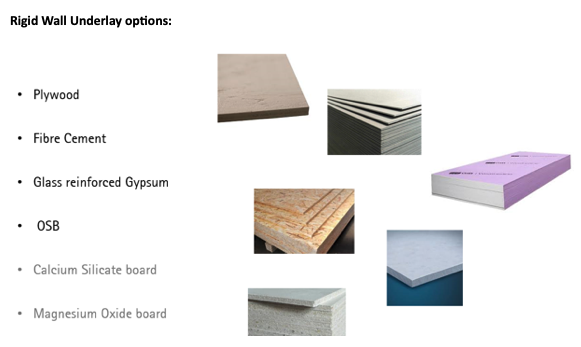

Rigid wall underlays (RWUs) behind claddings became mandatory from Version 3.0, no matter the wind zone or building location. Rigid wall underlays are a multi-purpose building control layer, as they may provide fire resistance, bracing, weathertightness and acoustic benefits in one layer. Proprietary rigid wall underlay systems (such as JH RAB, GIB Weatherline, CHH Ecoply Barrier) typically include taped joints. However, some RWU products require a full-coverage self-adhesive underlay to be applied in lieu of tapes where rainscreen claddings are used, or in SED/ high wind load applications.

In high seismic zones, a fibre cement rigid wall underlay must be overlaid with a flexible wall underlay, or BRANZ appraised self-adhesive underlay to ensure the integrity of the weathertightness layer is maintained in case the RWU is damaged during a seismic event. This gives the client (the MOE) peace of mind that the weathertightness of the building envelope will more likely perform as intended following an earthquake, as the RWU cannot be easily inspected for damage. Self-adhesive wall underlays are a ‘belts and braces’ approach for all buildings, as the full coverage of the RWU surface ensures all screw holes, cracks and joints are covered, and potential water ingress through holes is limited due to the underlay being fully adhered to the RWU surface. pro clima’s SOLITEX EXTASANA ADHERO self-adhesive underlay is suitable for this application.

Roofing

One of the major changes in Version 3.0 of the document was the type of materials allowed for roofing. For metal roofing, the roof underlays used must be BRANZ appraised, have side and end laps of 150mm or more, have all penetrations and laps sealed, and be an absorbent, vapour-permeable synthetic self-supporting type compliant with table 23 of E2/AS1. Despite requiring underlays to be self-supporting, a mesh is still required to be used to avoid sagging of the underlay if not already positioned over a rigid sheathing or rigid insulation. pro clima’s SOLITEX MENTO 3000 connect is suitable for this application, with the connect adhesive strips providing quick and effective sealing of the laps without additional tape.

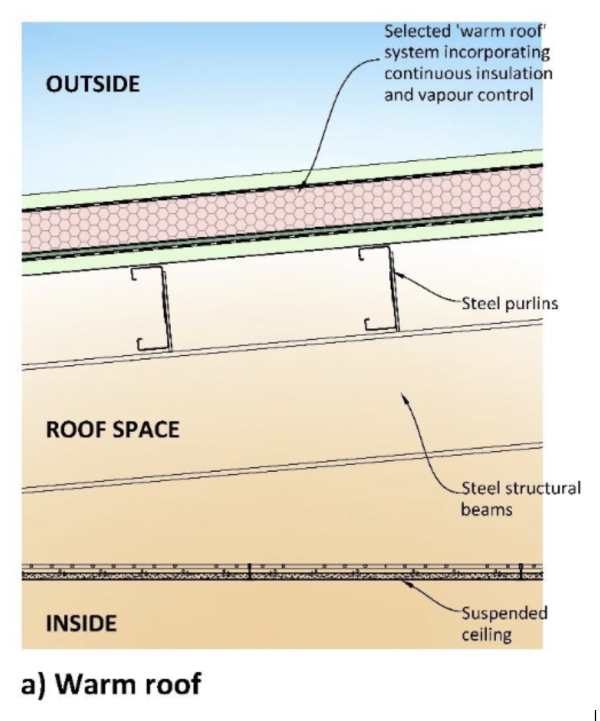

For school buildings constructed from steel framing, the roof must be a warm roof system. A warm roof is where all the insulation is placed to the outside of the structure so that steel structure stays warmer and above the dew point. Steel is much more conductive than timber (500-1000x), so the risks of interstitial condensation, corrosion and dampening of surrounding materials is much higher if the steel framing is cold, which it will be if bridging between inside and outside the building’s thermal envelope. There are now several suppliers of warm roof systems on the market, with a variety of roofing profiles available to meet both practical and aesthetic requirements.

Warm roof image from the document

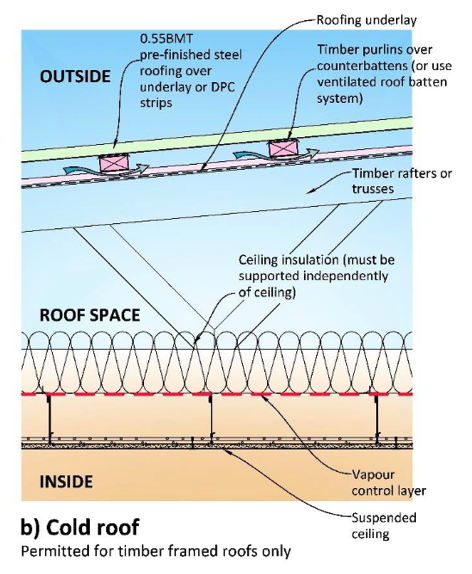

Cold roofs (where the insulation layer is within ie. skillion roof- or below the roof framing) are still permitted under the current version of the document, but only with timber trusses or rafters. As mentioned above, timber, while still being more conductive than insulation, is much less conductive than steel. The cold roof detail shown in the current version of the weathertightness document is a cold roof, but not as you may know it. The design of the permitted cold roof goes over and above standard practice, or what is shown in E2/AS1, to ensure more efficient removal of heat in the hotter months and better moisture management in the cooler months.

Cold roof image from the document

Like the pro clima Construction Details for roofs, the example given in the MOE document shows the roof underlay being fixed directly to the timber rafter or truss, with a vertical counter batten running up the rafter which lifts the purlin off the underlay to provide a clear ventilated path between the underlay and the metal roofing. Like the top venting of wall cladding cavities required in the document, the vented roof cavity provides inlets at the soffit/eaves, and outlets at the ridge to provide the air change and moisture removal.

Additionally, the roof cavity must also be vermin proof, so it requires selecting vent strips or perforated flashings, which allow plenty of air flow but not the pesky vermin.. For more information on ventilated cold roof systems, check out our ASV Technical Articles.

The ‘roof’ or attic space needs to be independently ventilated, as shown on the pro clima Truss roof detail, as it is a cold air space outside the insulation layer. A continuous vapour control layer is required in the MOE detail below the ceiling insulation layer. School classrooms have a high occupancy compared to a residential building, so the potential moisture loading into the building envelope is high. Vapour control layer INTELLO PLUS massively reduces the loading of moisture into the envelope. This keeps the insulation dry and minimises the risk of mould growth on moisture sensitive elements.

All in all, the design requirements set by the Ministry of Education represent a significant step towards protecting our future school assets. They have intentionally provided guidance and details that are above current building code requirements to avoid the mistakes of the past.

If you would like to discuss how pro clima can assist with the application of these requirements on your next school project, give us a call on 0800 PRO CLIMA or email [email protected]

Most Popular

Most Popular Popular Products

Popular Products