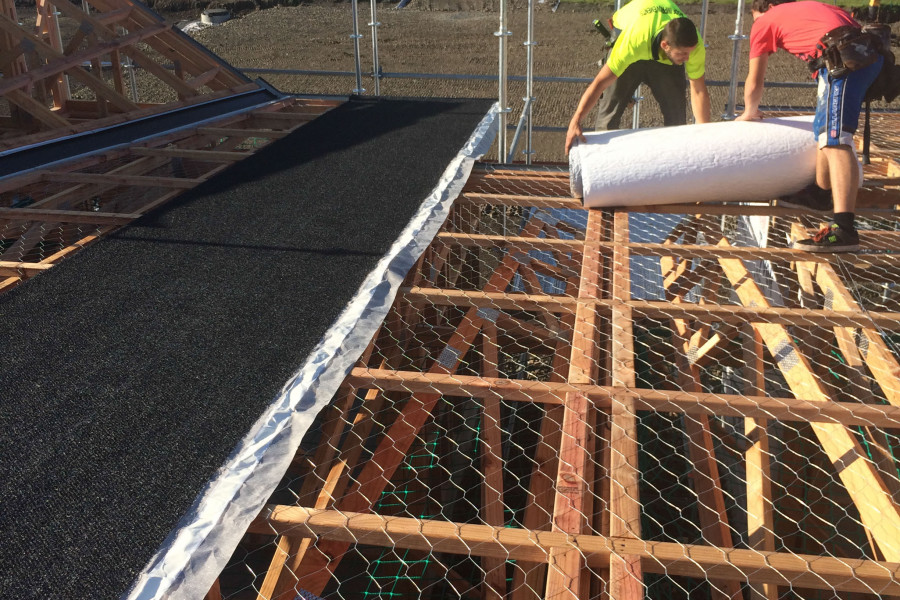

Air and water leakage at roof underlay overlaps is an age-old problem. The unique, built-in adhesive strip of DuPont Tyvek Supro Plus helps reduce air and water infiltration at overlaps to provide superior protection of the roof enclosure.

DuPont Tyvek Supro Plus is CodeMark certified to ensure compliance with NZBC E2/AS1, B2 and F2. It is recommended for use as a self supporting (R2) roof underlay on most roof pitches greater than 3º including the following roof cladding types:

- Concrete, clay and slate tile

- Profiled metal and pressed metal tile

- Asphalt shingle

It is not recommended for membrane roofs.

Other benefits of DuPont Tyvek Supro Plus Roof Underlay include:

- Fire retardant per AS 1530 part 2 (fire flammability rating of 3)

- Breathable (high Moisture Vapour Transmission Rate per ASTM E-96) which helps reduce condensation build up in roof assembly

- Suitable in NZS 3604 building wind zones up to and including extra high

- Non kraft paper based, meaning it may be exposed to rainfall during installation without affecting durability or performance

- Functional layer of 175 microns (up to seven times the thickness of other synthetics) which provides a robust, durable and UV resistant underlay to withstand job site conditions

- UV resistant for up to 120 days to allow plenty of time for cladding to be installed

DuPont Tyvek Supro Plus has similar performance qualities to DuPont Tyvek Supro which was originally introduced by DuPont to the building industry in Europe in the 1990s.

DuPont Tyvek Supro is now one of the most installed synthetic roof underlays in the world. DuPont Tyvek Supro Plus is made by laminating spunbonded high density polyethylene (HDPE) to a non woven polypropylene sheet. This manufacturing process provides a strong, weather resistant barrier with excellent moisture vapour permeability.

Building scientists refer to permeability as Moisture Vapour Transmission Rate (MVTR). Most scientists in New Zealand believe a building enclosure needs to be air and water tight, but vapour permeable. Vapour permeability allows buildings to dry from the inside out. This is significant when building materials often get wet during construction or later from occupant lifestyle choices. On metal roofs, the management of condensation is a key consideration.

DuPont Tyvek Supro was first introduced to New Zealand in the mid 2000s and has been installed on hundreds of residential and commercial buildings.

DuPont Tyvek Supro and DuPont Tyvek Supro Plus belong to the DuPont Tyvek Weatherization System. This system consists of synthetic wall underlays, synthetic roof underlays, 100% butyl adhesive flashing tapes, underlay cap fasteners and acrylic underlay seam tapes, manufactured and backed by DuPont, a 200 year old company.

Case Studies

Case Studies

Popular Products from Tyvek

Popular Products from Tyvek

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts