Material choice:

Ventilation providing drying should occur outside the weathertightness envelope. This conflicts in part with Stuart Thomson's excellent article 'Ventilation of Attic Spaces'? [MRM SCOPE, issue 35]. Users all want buildings to perform better and last longer. The conflict in opinion and information is largely due to material choices, and expectations of their performance.

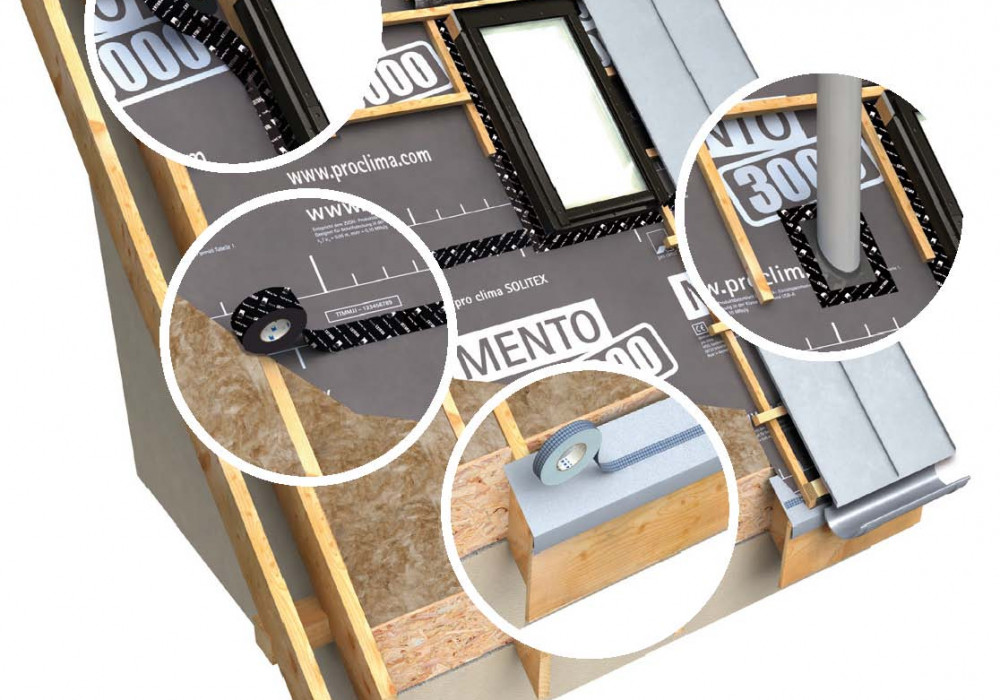

Convective air movement around insulation is not required for drying when using non-porous SOLITEX roof underlays.

Gap theory:

The commonly accepted 25mm air gap above the insulation is to avoid wicking moisture through 'old-technology' of porous roof underlays. This can occur at the wall/roof junction in a trussed roof or continuously in a skillion roof. However the resulting convective air movement reduces the performance of the insulation.

A better approach is to firstly protect the insulation from this wind movement (wind-wash), reduce the moisture loading into the structure from internal sources, and still allow for drying of the structure by diffusion.

The '25mm air gap' went against acceptable solution E3/AS1 Internal moisture Clause 1.1.4.b until this clause was deleted in 2014. It stated 'For the construction to be acceptable: …b) 'Insulated cavities shall be enclosed with no ventilation.' On face value a 25mm gap seems like common sense but is not always applicable or easily achievable.

No wonder designers are confused: a standard wall construction still follows the 'enclosed' (still-air) principle with no cavity. At what angle does a wall become a roof?

Drying capacity: A design issue? Or a materials and design issue?

Designing accurately is not possible if we rely on wind pressure and infiltration to provide drying capacity. As Stuart points out "…the designer's judgement will determine the success or failure of the ventilation design."

The safest approach is to reduce the amount of internal moisture allowed to infiltrate the building envelope.

Downlights are chimneys, plasterboard is diffusion open, and so is the paint attached to it. A structure allowing moisture ingress needs to allow for even greater drying capacity. At this point the challenges and complexity overtake the construction’s predictable performance. For example, the latest 'gap' being recommended is in the roofing underlay at the apex/ridge, due to a lack of initial moisture control from internal spaces.

Design:

So let’s start by designing (roofs) with insulation, airtightness, and ventilation in mind. Insulation creates a difference between inside and outside climate. Airtightness prevents significant air and moisture infiltration through the fabric of the building. Ventilation should deal with the moisture generated inside the home.

We can stop relying on unpredictable factors such as wind speed and infiltration to provide drying and 'ventilation' of internal spaces.

Paragraph three of Stuart Thomson's article 'Ventilation of Attic Spaces' states: "Many were labelled as leaky homes when they were not leaking from the outside!"

Just as he had "ideas about how to do things better", and "came up against the 'old-school' attitudes of his father" [MRM Scope 38] in 1951, Pro Clima is glad there was then, and is now, the uptake of useful technological advancement.

It is needed.

Case Studies

Case Studies

Popular Products from pro clima

Popular Products from pro clima

Posts by Pro Clima Technical

Posts by Pro Clima Technical

Most Popular

Most Popular