Of the changes made to H1, window performance is the most significant. Unlike other building elements, the occupants of the building are really going to feel this change. But the feeling of comfort is not guaranteed, H1 is a blunt tool focused on thermal performance and energy savings.

Building designers need to understand the real-life implications that decisions on window selection have on the building’s occupants. Blindly following the glazing table in H1/AS1 Table E.1.1.1 and installing windows to E2/AS1 can lead to contrary outcomes.

Ideally a window should meet or exceed H1 requirements but with consideration to thermal bridging, and the risks of condensation and overheating.

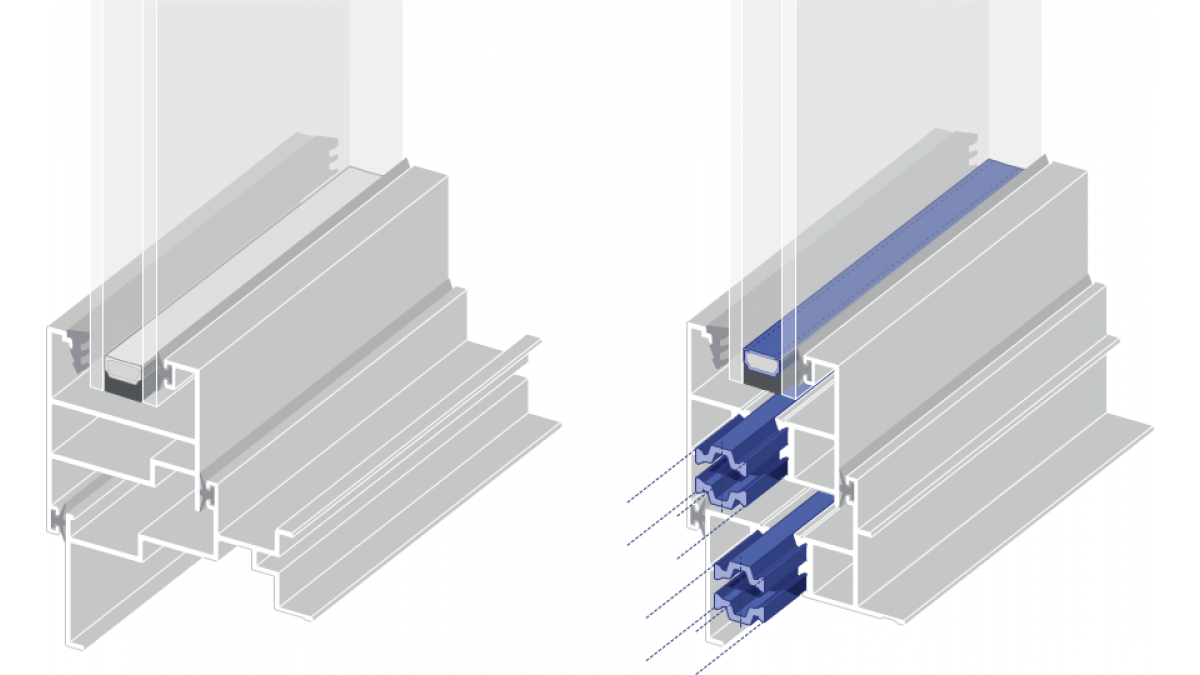

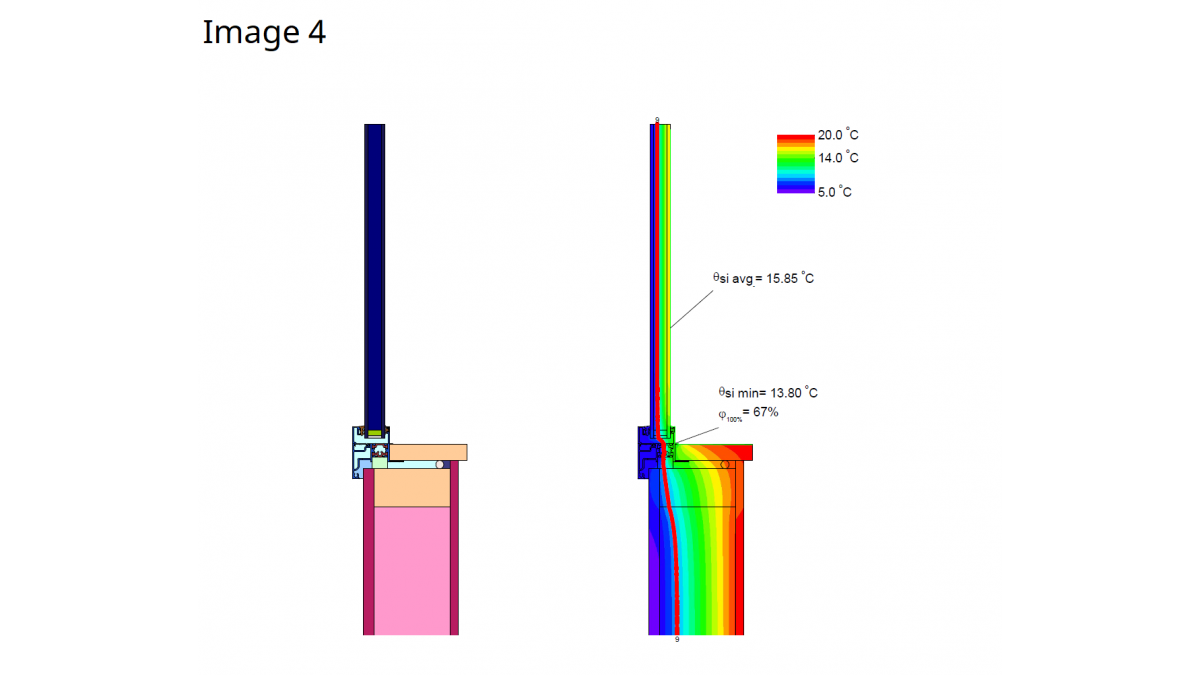

H1/AS1 allows the use of windows meeting an R value of R0.37 m²·K/W in climate zones 1 and 2. By following the schedule method, window performance can be selected based on the table found in section E.1.1.1. From this table an aluminium frame and double glazing with a Ug of 1.1 and a warm edge (thermally improved) spacer meets the minimum requirement (see image 1 in carousel).

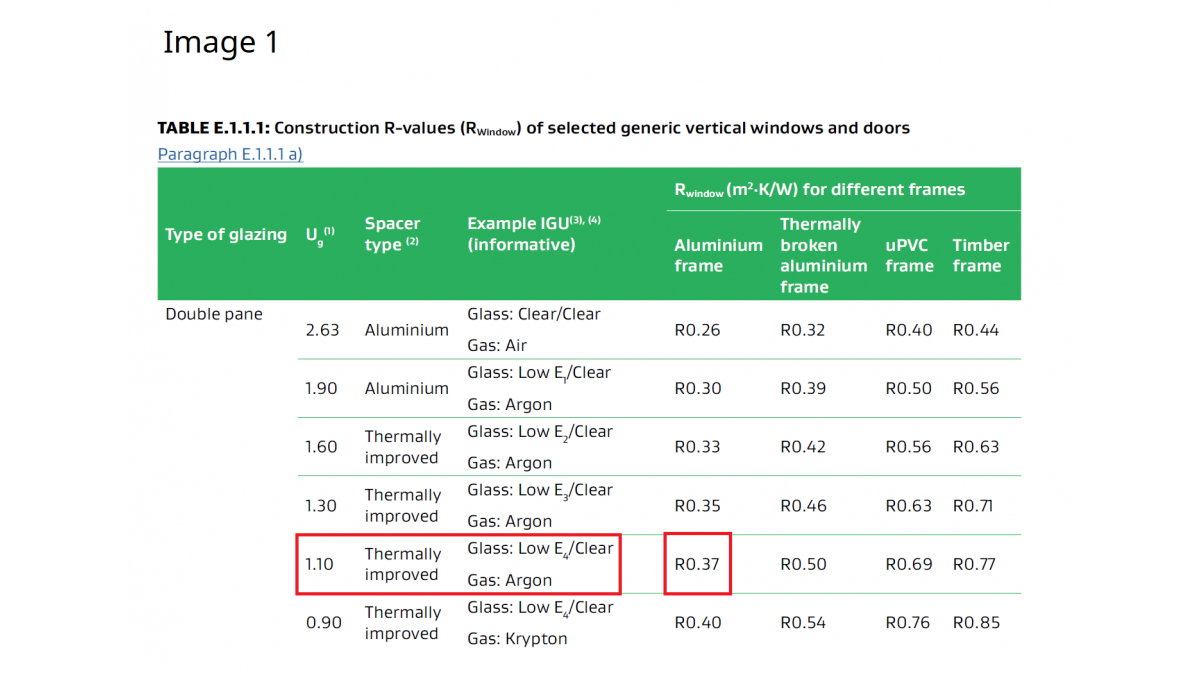

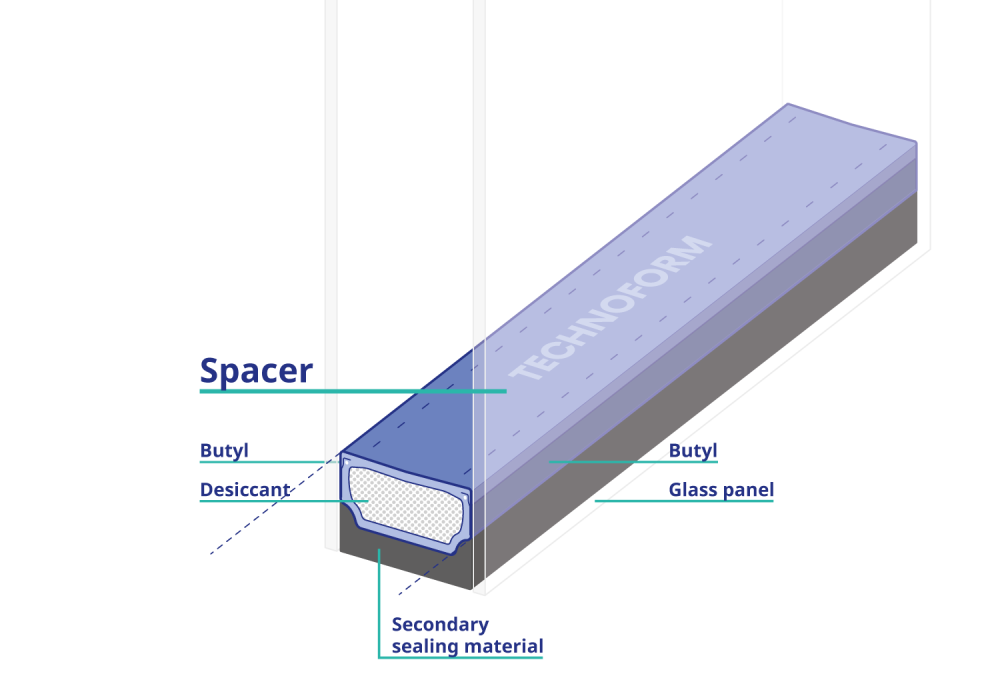

However, meeting the minimum requirement does not necessarily result in a good outcome for the occupants of a building. Using thermal analysis software, it is possible to look at cross sectional details of window junctions to check how a window performs under specific conditions. The details in image 2 show an R0.37 window selected from the table installed to E2/AS1. The detail to the right is the same window modelled with 5°C external temperature and 20°C internal temperature.

This model identifies the minimum surface temperature at the window junction being 7.9°C. The thick red line running up the window represents a theoretical dew point temperature at 9.0°C (a room heated to 20°C with 50% relative humidity). The red line is visible on the aluminium frame which means there is a high risk of condensation forming. This is not a good outcome for the occupants.

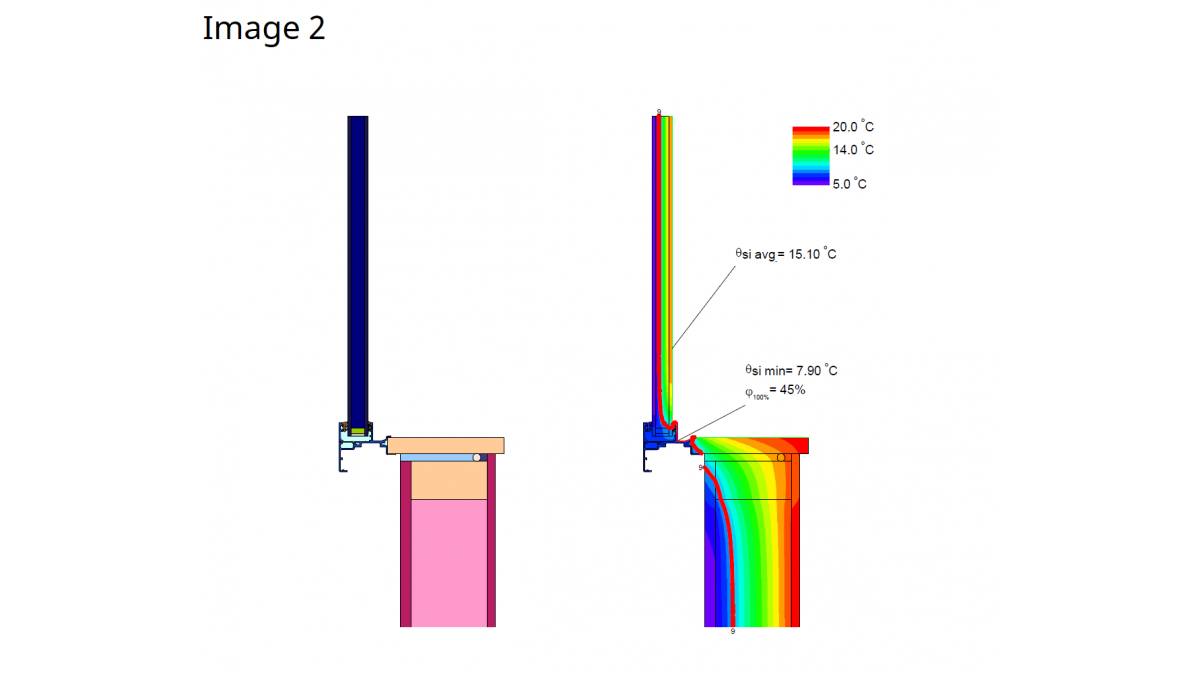

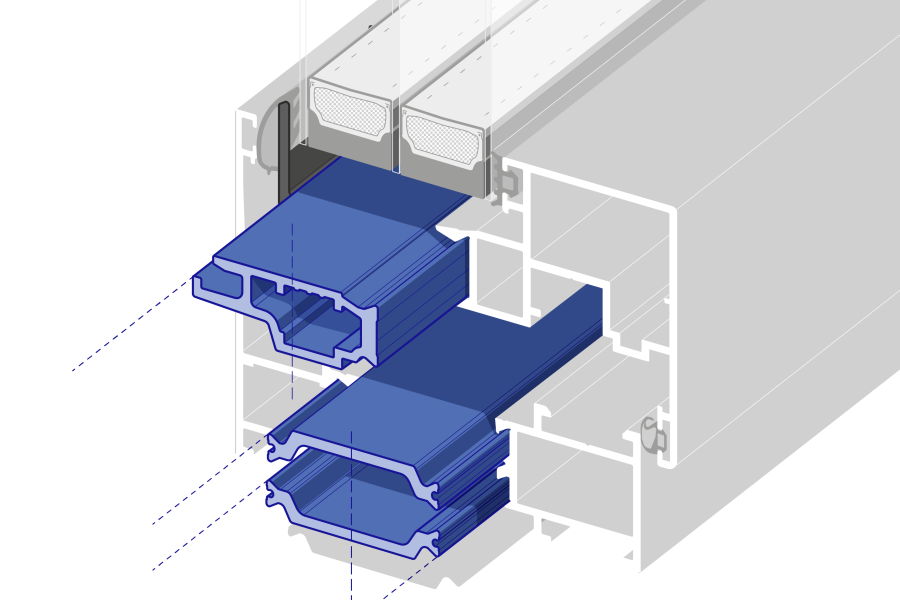

Alternatively, a balanced approach to thermal performance should be taken. Using the same tables, it is possible to specify a thermally broken aluminium frame with a lower performing double glazed unit (see image 3). An exception made is for the use of a thermally improved spacer rather than an aluminium spacer. This window has an R value of 0.39, virtually the same performance as the previous example (in fact slightly better) but it has been installed recessed into the structure and in-line with the insulation layer.

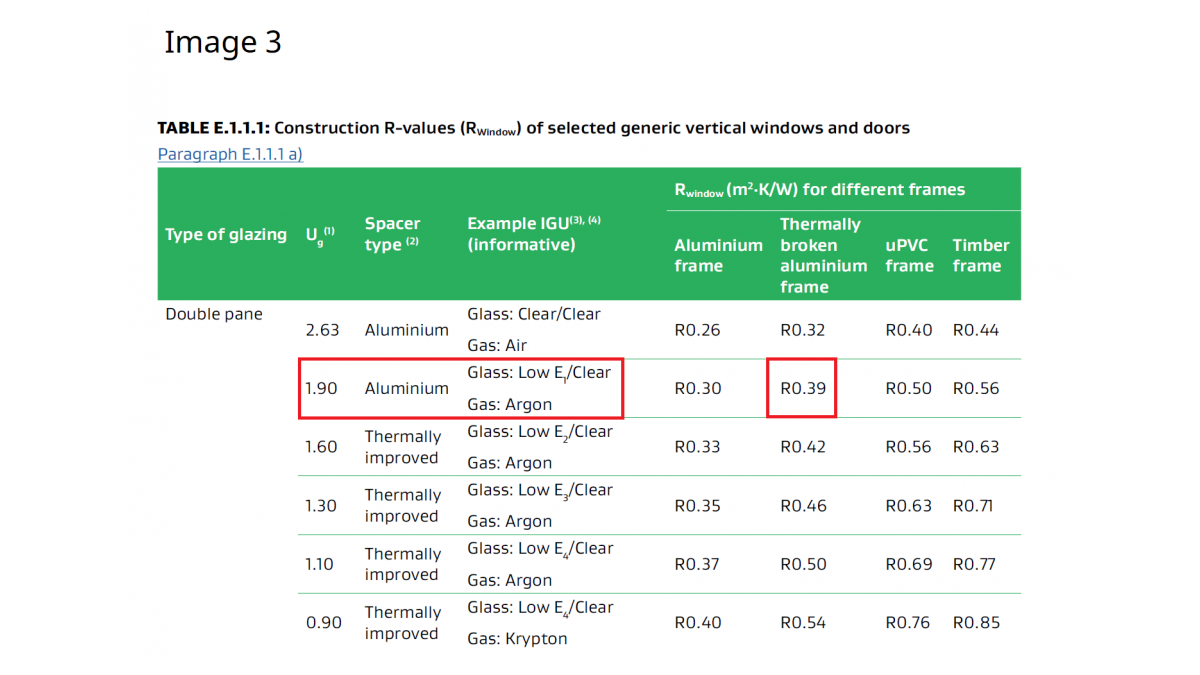

The minimum surface temperature at the window junction is now 13.8°C (see image 4) and at 50% relative humidity there is very little risk of condensation forming on the surface of the frame. This window specification and installation detail will significantly reduce the chance of mould growth and increase the perceived comfort of the occupants.

On paper windows may appear to have almost identical thermal performance, it’s critical to have this information at hand so informed decisions can be made.

Case Studies

Case Studies

Popular Products from Technoform

Popular Products from Technoform

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts