When purchasing a newly built home, buyers typically do not expect to encounter issues such as condensation or mould — problems generally associated with older, poorly insulated houses. Unfortunately, these problems can arise quickly in new homes due to common construction flaws. To promote healthier and more energy-efficient living environments, it is essential to improve insulation techniques and utilise advanced materials.

This article will step you through current H1 energy efficiency wall performance and introduce thermally improved design solutions to enhance energy efficient designs.

Current wall performance standards

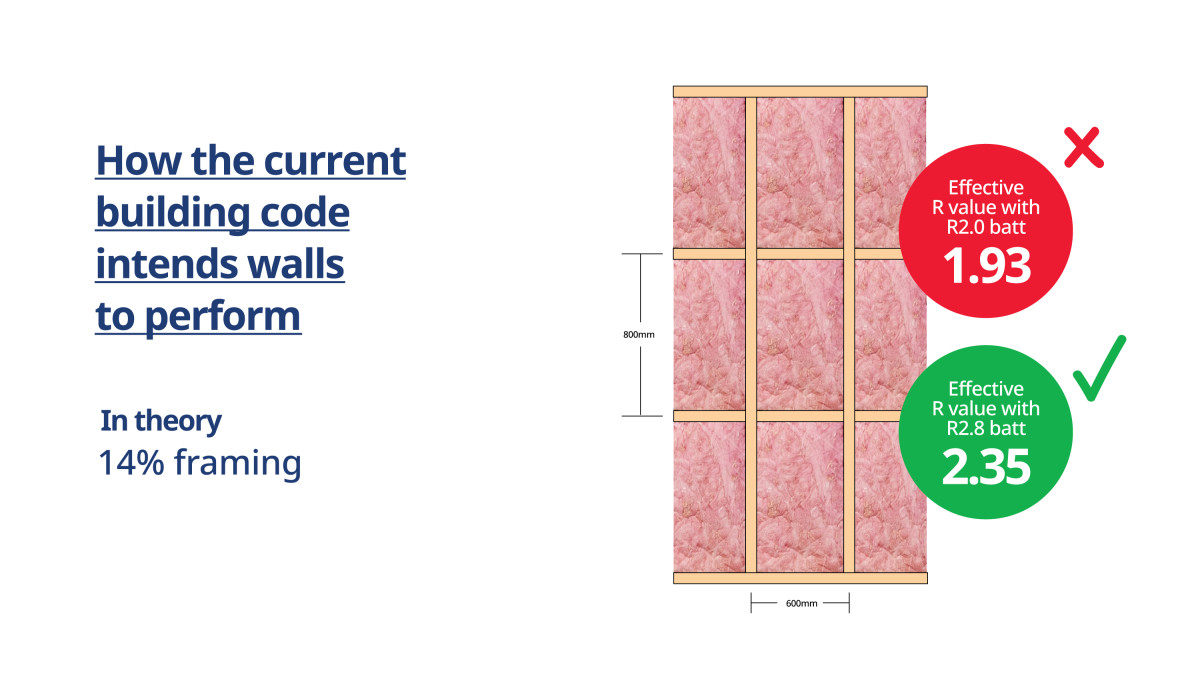

New Zealand's building code, specifically Clause H1, Energy Efficiency (H1 AS1), requires that walls have a minimum effective R-value of 2.0. This value is currently determined based on a theoretical wall framing fraction of 14%, which represents the ratio of timber to insulation. However, in practice, thermal performance frequently deviates significantly from these theoretical expectations.

R-values with a 14% framing fraction:

- An R2.0 batt delivers an effective R-value of just 1.93.

- An R2.8 batt, under optimal conditions, achieves 2.35.

Refer to image 1 in the gallery above

Council inspections: Challenges in wall construction

Construction standards still face further hurdles, as shown by information from Auckland City Council building inspectors.

- 27% of pre-line inspections fail. There are various reasons for these failures, however, when it comes to walls, the primary causes relate to inadequate insulation or unverified R-values.

- 31% of final residential inspections also fail. Once more, there are various reasons for inspection failures. However, concerning walls, the main causes are linked to improper insulation installation, including gaps, folds, or excessive moisture in the framing.

Insights from Research on Housing Performance

BRANZ research concluded that over half of New Zealand's housing stock does not meet minimum insulation standards. This leads to widespread under-heated homes and higher heating costs. According to research by Rochelle Ade and Michael Rehm (2020), even newly constructed social homes in Auckland spend approximately 64% of winter below 18°C, far from the warmth needed for comfort and health.

Poorly selected or insufficient insulation can lead to damp and cold indoor environments in New Zealand's temperate climate. When insulation fails to maintain consistent temperatures, condensation becomes a recurring issue. This moisture creates a perfect breeding ground for mould, particularly in walls, ceilings, and underfloor spaces.

According to IAQ Research Centre New Zealand, compounding moisture build up in New Zealand homes is the 'lack of adequate ventilation built into the New Zealand building code' BRANZ (2019). Lack of adequate ventilation traps humid air indoors, preventing the moisture from dispersing. Without proper airflow, damp conditions persist, further encouraging mould growth. Over time, these hidden mould problems compromise air quality, health, and the structural integrity of buildings.

Alarmingly, according to the Asthma + Respiratory Foundation, New Zealand has the second-highest rate of asthma-related deaths in individuals aged 5–35 among high-income nations, primarily linked to the living conditions in our homes. Respiratory diseases cost New Zealand $8 billion annually and affect one in 11 hospital stays, underscoring the pressing need for better housing solutions.

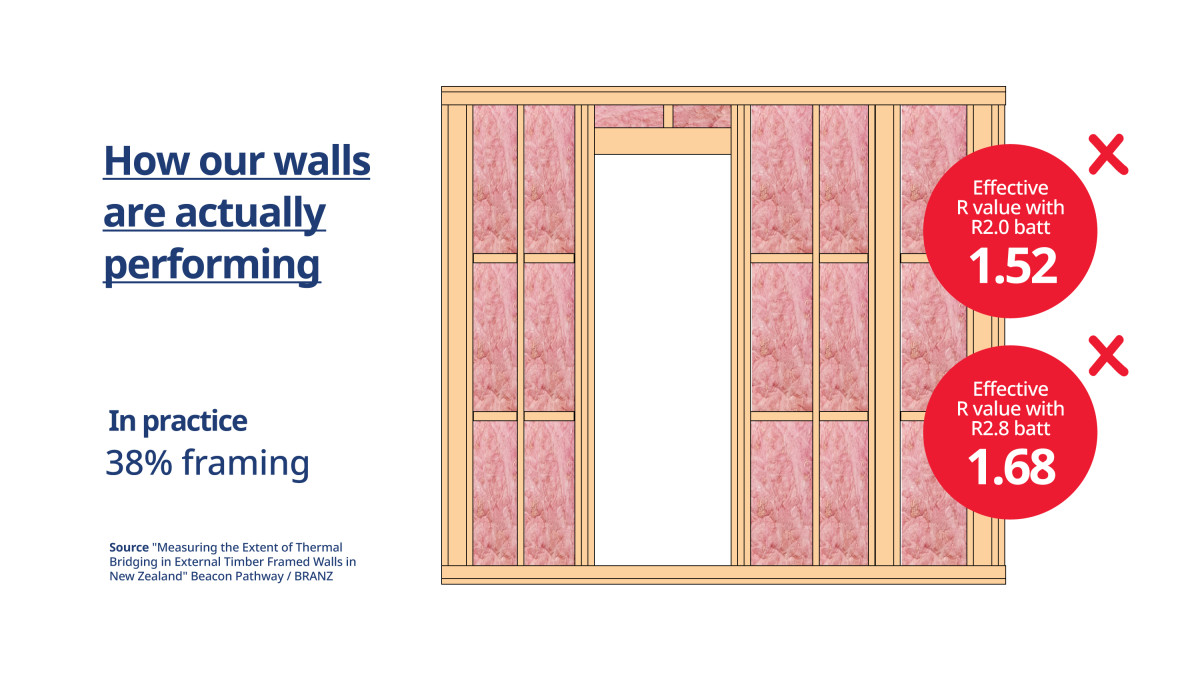

Discrepancies in framing fractions: Bridging the gap between models and reality

Research by BRANZ and Beacon Pathway (2020), supported by insights from Placemakers Framology software, revealed that wall framing fractions average 38% — a stark departure from the currently expected 14%. In December 2024 MBIE proposed an increase to 38% for wall framing fractions in H1 energy efficiency clause.

This proposed shift to a 38% wall framing fraction has critical implications for wall insulation performance.

90mm framing:

- R2.0 batt achieves an actual R-value of just 1.52.

- R2.8 batt achieves an actual R-value of just 1.68.

refer to image 2 in the gallery above.

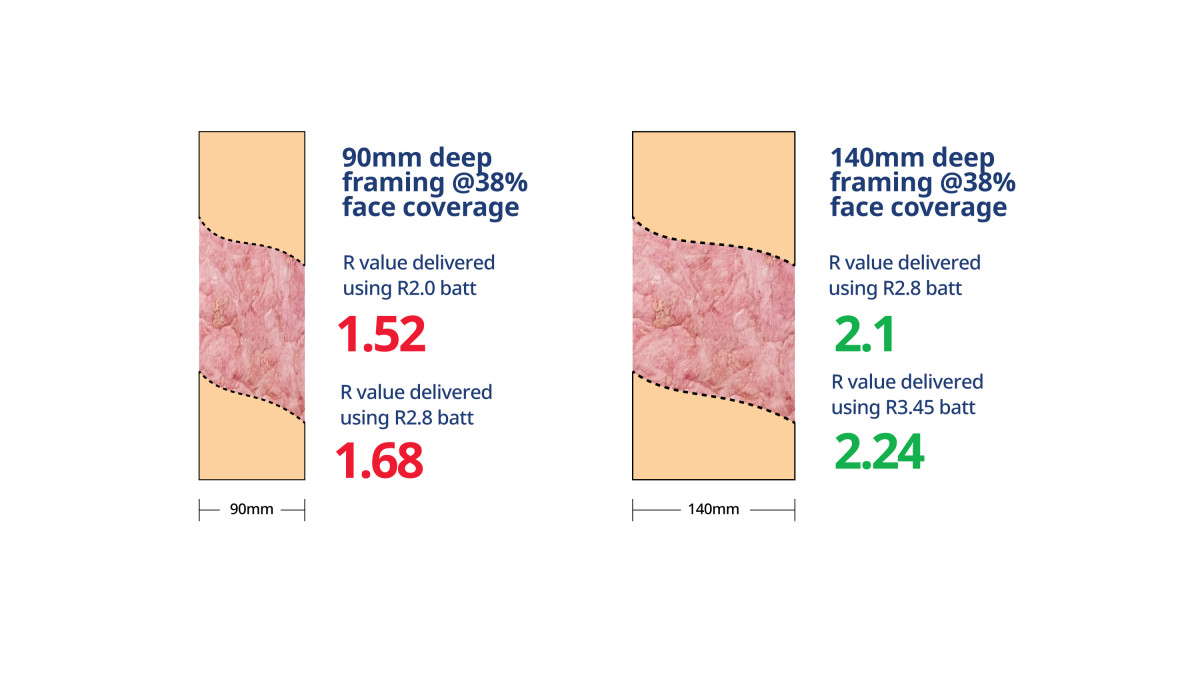

140mm framing:

- R2.8 batt improves performance to R2.10.

- R3.4batt improves performance to R2.24.

refer to image 3 in the gallery above.

Interstitial condensation, the unseen enemy

Buildings in New Zealand are become more airtight and interstitial condensation occurs when warm, moist air penetrates a wall and meets a cooler layer, causing the moisture to condense inside the wall cavity MBIE, (2020). Over time, this trapped moisture creates an environment conducive to mould growth, often hidden within the structure. The mould thrives in damp, dark spaces, releasing spores that can affect indoor air quality and pose health risks, all while remaining unseen until significant damage occurs.

This indicates that the selection and installation of substandard insulation, coupled with outdated construction methods, can have serious consequences:

- Decreased thermal efficiency

- Mould and mildew growth

- Health problems

- Rising household costs

- Surface staining and odours

- Sustainability challenges

- Structural damage

Embracing advanced materials and construction strategies is no longer optional — it's essential.

Separate critical wall layers

The performance of a building greatly depends on how well its wall assemblies manage different roles. Keeping the critical layers of wall assemblies distinct provides a robust strategy for enhanced energy efficiency and durability. Here's how these layers contribute:

- Layer 1. Exterior Cladding: Acts as a rain screen, protecting against environmental elements.

- Layer 2. Dedicated External Insulation Layer: Boosts thermal resistance.

- Layer 3. Rigid Air Barrier or Weather-Resistant Barrier: Adds protection against air and moisture infiltration.

- Layer 4. Structural Framing: Supports the assembly while providing space for services, minimising thermal performance impacts.

These layers create a high-performing, durable building envelope for externally insulated facades.

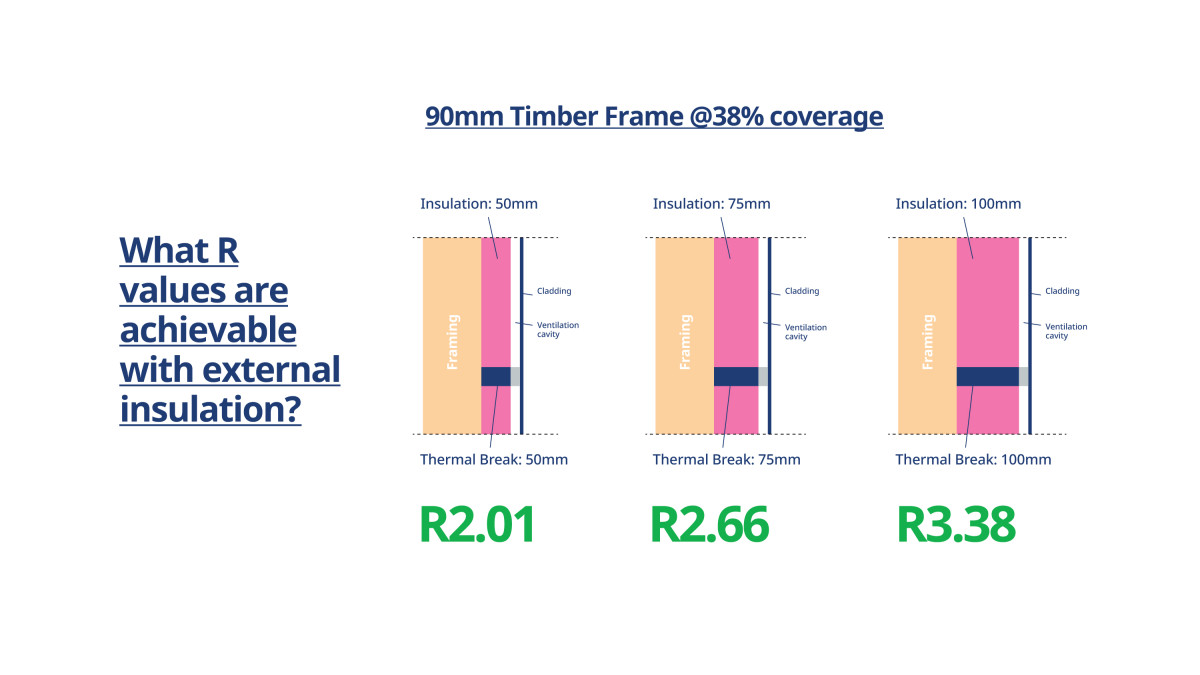

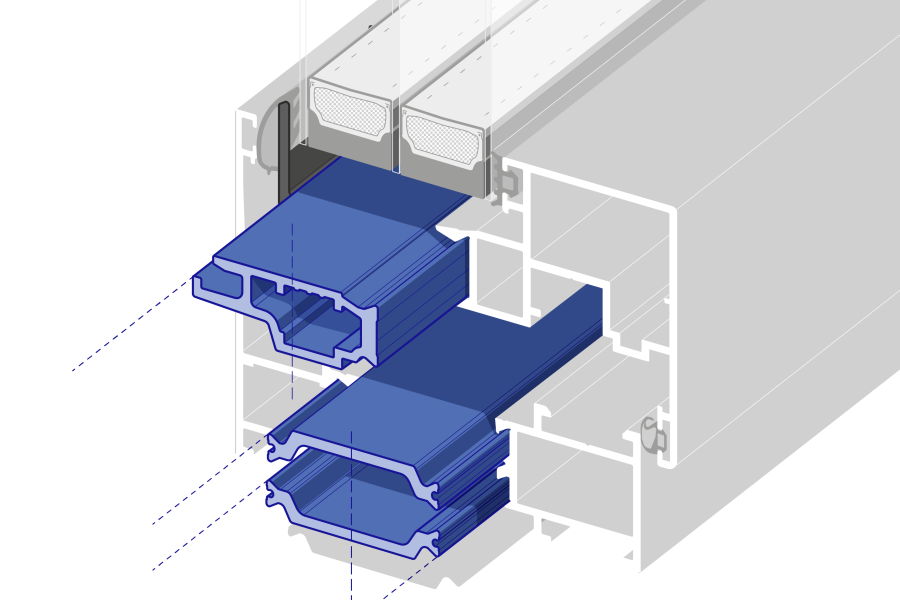

Externally insulated facades

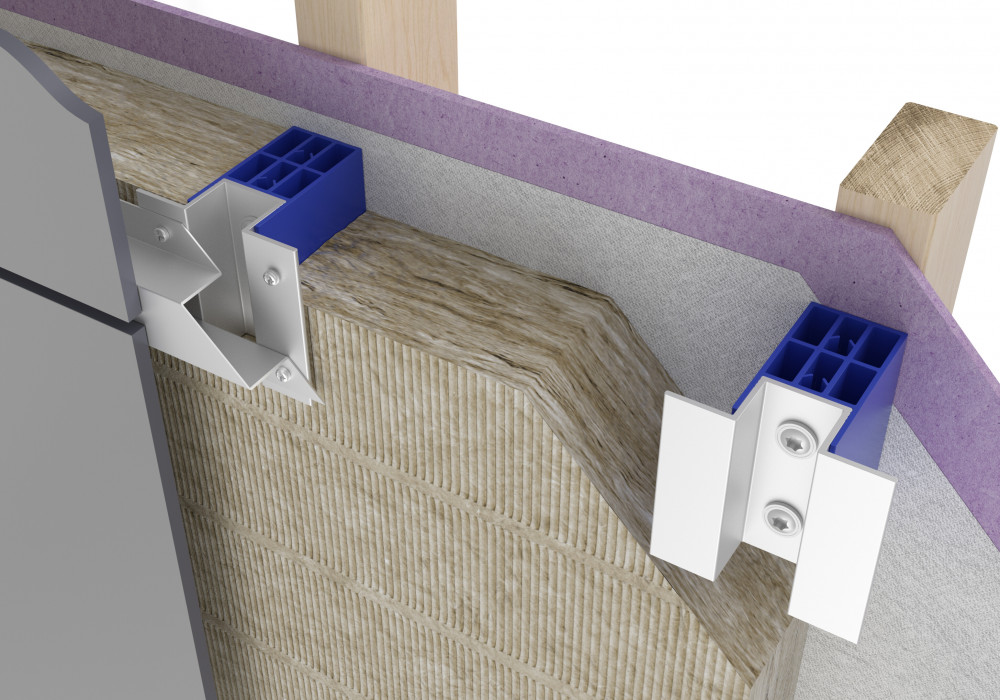

External insulation systems offer advantages by providing a continuous thermal barrier. However, point thermal bridging — a common challenge — often compromises performance. This issue occurs when traditional metal clips or fasteners penetrate the insulation layer, creating weak points in the building's thermal envelope.

Introducing thermally isolated clips:

- Made from polyamide, 40% glass-reinforced nylon, the clips are significantly less conductive than aluminium.

- Reduce point thermal bridging to maintain the effectiveness of the insulation.

- Improve overall wall performance by maintaining the dew point outside the structural layer, thereby reducing the risk of condensation.

External facades achieve improved thermal resistance by incorporating thermally isolated clips and addressing common issues such as mould and moisture.

90mm timber framing with 38% wall framing fraction:

- R2.01 for external insulation with 50mm thermally isolated clips

- R2.66 for external insulation with 75mm thermally isolated clips

- R3.38 for external insulation with 100mm thermally isolated clips

Refer to image 4 in the gallery above.

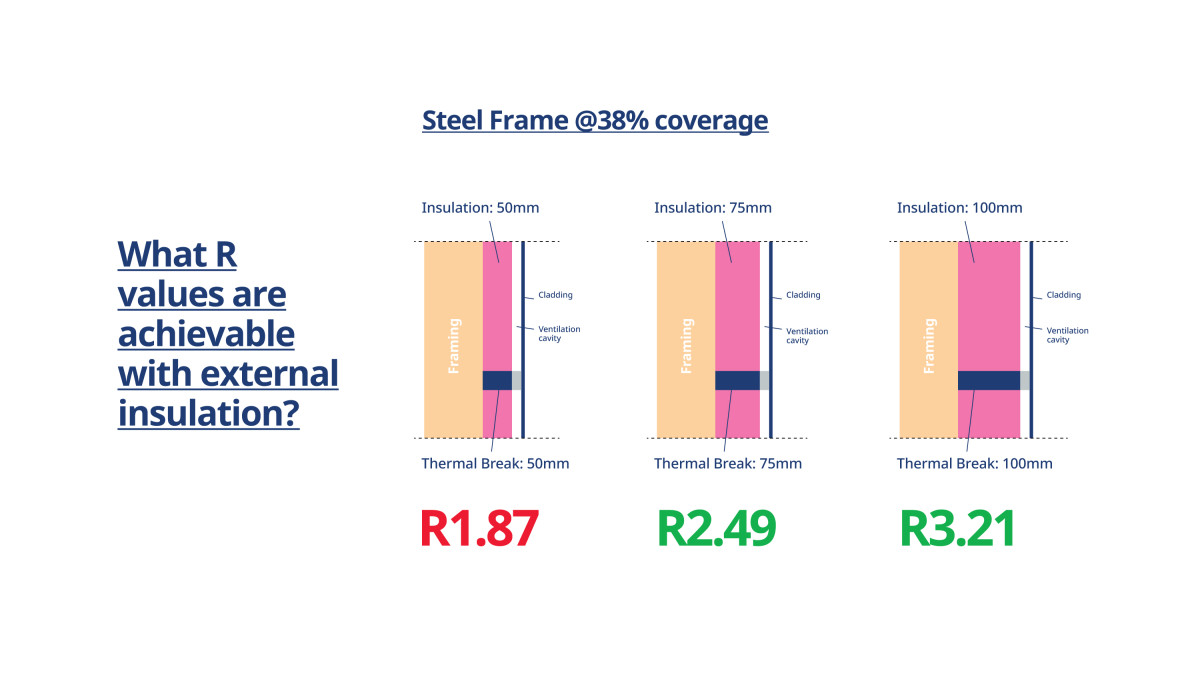

Steel framing, known for its high thermal conductivity:

- R1.87 for external insulation with 50mm thermally isolated clips

- R2.49 for external insulation with 75mm thermally isolated clips

- R3.21 for external insulation with 100mm thermally isolated clips

Refer to image 5 in the gallery above.

A Call to Action

Architects and designers play a vital role in shaping the future of building performance. Guiding clients toward solutions like external insulation and thermally isolated clips helps to deliver:

- Healthier living spaces: Reduced risks of condensation and mould.

- Sustainability: Lower energy use and carbon footprints.

- Lifecycle cost savings: Long-term benefits for developers and homeowners.

Remember the best time to invest in the thermal envelope is during construction. While external insulation systems may involve higher upfront costs, their long-term savings and benefits make them a worthwhile investment. By advocating for these innovative practices, architects and designers lead the charge toward better-performing homes that meet and exceed New Zealand's energy goals.

Regardless of whether you are designing a granny flat, or an 11-storey apartment building, external insulation with thermal isolator clips will work for your project.

Let's create buildings that deliver on their promises — offering health, comfort, and sustainability for future generations.

To learn more about these R-value calculations, get in touch with Technoform's technical team.

Case Studies

Case Studies

Popular Products from Technoform

Popular Products from Technoform

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts