Established in 1985, Nu-Wall is one of New Zealand’s leading aluminium cladding specialists, with products and systems designed and manufactured in New Zealand, enabling a reliable and resilient supply chain. Nu-Wall Cladding is a high-performance, low-maintenance and non-combustible BRANZ-appraised cladding system, with a 100-year base metal durability warranty. Nu-Wall are committed to providing innovative product designs that market needs in terms of aesthetics, functionality, and sustainability.

Design and construction considerations

Some key design considerations so you can get the best out your Nu-Wall cladding.

1. Nu-Wall Compliance Path

The Nu-Wall system has three configurations that have been appraised by BRANZ as an alternative solution for use up to 2.5Kpa wind zones. The product is supplied as a system with components supplied as a kit set. Nu-Wall have extensive independent tests that are available to aid compliance for more complex designs and applications (E2/VM2- structures to 25m height, seismic racking, NZS4284, commercial face load tests).

Please view the Nu-Wall General Product Statement, which details the various compliance path options.

2. 2D CAD details

Nu-Wall offers an extensive resource library of CAD files, specifications, compliance, and technical data to ensure the optimal application of Nu-Wall products in diverse architectural applications. Plus, all CAD detail sets have recently been updated.

To make compliance easy, always refer to and follow these appraised details in Nu-Wall's CAD Library.

3. Framing accuracy

Ensure framing is manufactured and installed to NZS3604 standards and specifications. The straightness of the framing will impact the installation accuracy and final product. Out of plumb framing is a major contributing factor to cladding misalignment which can cause various problems over time.

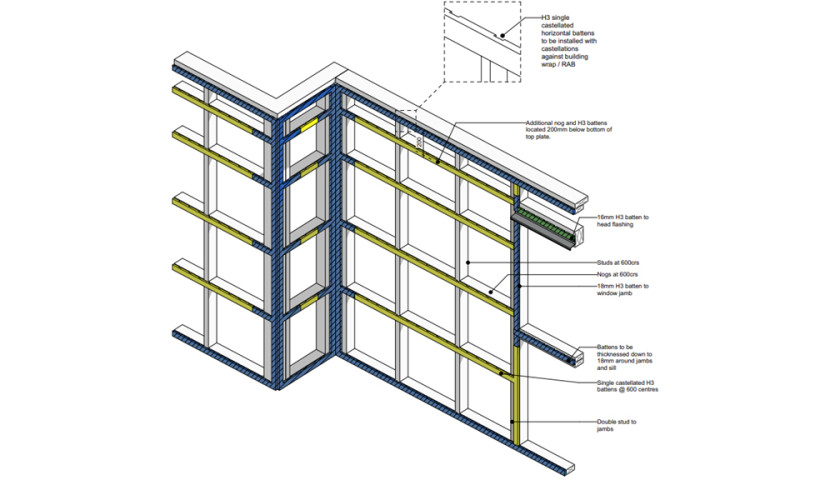

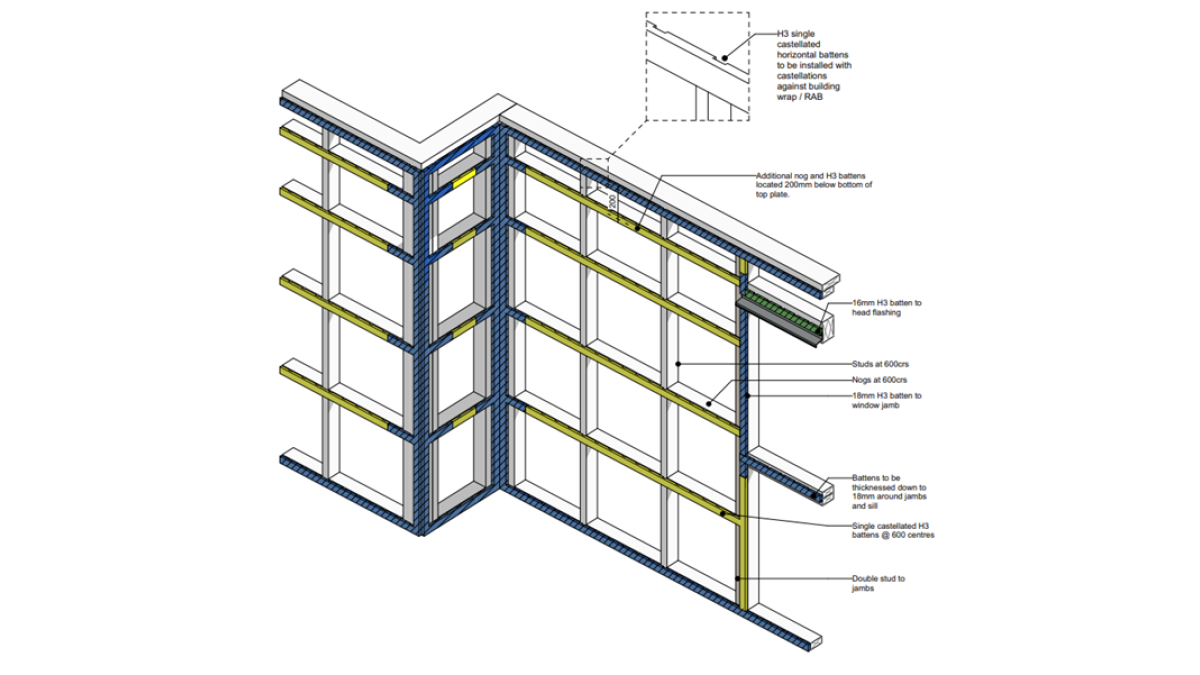

4. Cavity batten selection

Nu-Wall vertical cladding can be installed over 20mm single castellated, 45mm single castellated structural timber battens, or 20mm AliBat structural, non-combustible, aluminium batten.

Nu-Wall offers an 18/20 single castellated cavity batten set (18mm and/or 20mm battens). This system allows for back-flashing buildup while still achieving a flat cladding surface.

The 18mm battens are depicted in blue in the graphic above.

5. Thermal movement

All metal cladding products are subject to the effects of thermal change and the design needs to allow for this expansion and contraction.

The Nu-Wall system is designed to allow free board movement, when subjected to thermal movement.

Lightweight accessories such as signage, bulkhead lights and residential gutters, should be fixed to the Nu-Wall only — and not penetrate through to the structure, which would prevent free board movement.

The through-cladding fixing of decks, pergolas, louvres and window shrouds, need to be specifically detailed to allow free board movement and we encourage a discussion with technical team.

View the Nu-Wall Wall Requirements and Seismic Movement Guide

6. Specific Design Considerations

The following design elements require additional detail to show compliance.

- Curved, raked and angled surfaces

- Inter-storey joint placement

- Tight joinery to corner placements

- Parapet, saddle flashing junctions

- Cavity depth variation that require custom fabricated flashings

- Recessed windows

- External insulated walls

7. Technical support

Nu-Wall's technical team is recognised for its practical, solution-oriented expertise in compliance and detailing. They support specifiers from concept through construction with guidance that helps avoid RFIs and ensures smooth council processing.

Take advantage of this free service to achieve design clarity and build confidence from the outset.

For more information, visit www.nuwall.co.nz.

Project pictured by Box Build

Photo ©Sophie Heywood

Case Studies

Case Studies

Popular Products from Nu-Wall Cladding

Popular Products from Nu-Wall Cladding

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts