Machinery such as heating, ventilation and air conditioning (HVAC) systems can generate strong vibrations and radiating noise when operating. These strong vibrations can have a detrimental effect on occupants of a building, as they can cause high levels of irritation through noise radiation. Vibration can also shorten the service life of machinery.

According to a 2013 report compiled by the RMA Quality Planning Resource (p. 4), in addition to the most obvious detrimental health effect of noise induced hearing loss (NIHL), other effects of excessive noise levels include general annoyance, speech interference, performance, mental health and sleep disturbance.

One new technology assisting in vibration isolation and mitigation is Pyrotek Noise Control’s Sylomer, a specialised polyurethane elastomer material.

The elastic polyurethane material deforms under tension and compression loads, but always returns to its original form. Through this action, Sylomer isolates and reduces the vibrations that can have negative effects on people, the environment and materials.

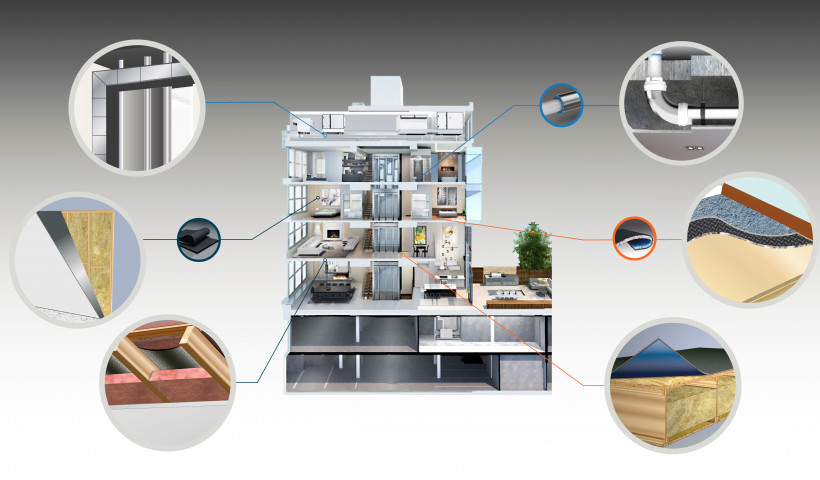

The isolation and reduction of structure-borne noise by Sylomer reduces not only the primary system noise level but also reduces secondary structure-borne noise within a building.

Product Features and Benefits

Features of Sylomer include the reduction of vibration and quieter system operation, reduction of secondary airborne noise and therefore overall reduced noise levels inside buildings, increased working comfort, and extended service life of equipment and machinery. Bearings are maintenance-free and easy to install, can be adapted to suit existing designs and are chemical, oil- and water-resistant.

The installation of Sylomer will effectively reduce vibration-induced noise from HVAC machinery, enabling rooms within buildings to meet the recommended noise reverberation times listed in the Australia/New Zealand Acoustics—Recommended Design Sound Levels and Reverberation Times for Building Interiors (2000).

Applications

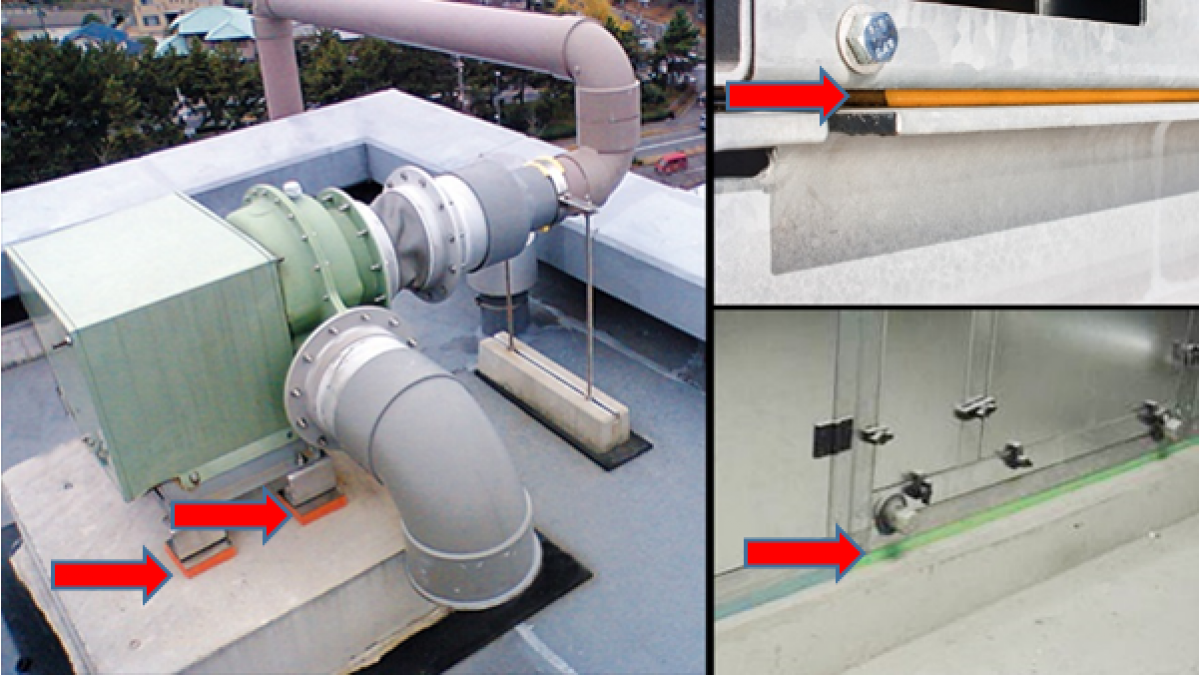

Used in commercial applications, Sylomer can be used for the bearings of HVAC systems, decoupling of fans, elastic bearings of compressors, elastic compensation layer and decoupling in pipework, machine mounts for various load situations, elastic decoupling of screw connections.

According to the RMA Quality Planning Resource (2013, p. 7), mechanical plant equipment was one of the main sources of excessive noise emissions in commercial buildings, however, improved technology means better control of noise emissions through lower sound output from modern mechanical sources (such as compressors, pumps, motors and fans). Sylomer works to reduce the impact of commercial noise.

Reference List

- Australia/New Zealand Standard, 2000, 'Acoustics – Recommended Design Sound Levels and Reverberation Times for Building Interiors'.

- The RMA Quality Planning Resource, 2013, 'Plan Topics: Noise Management in Mixed-Use Urban Environments', retrieved 29 September 2014, here.

Further Reading

- enHealth Council, 2004, 'The Health Effects of Environmental Noise – Other Than Hearing Loss'.

- Getzner Wekstoffe, 2014, 'Materials', retrieved 25 September 2014, here.

Case Studies

Case Studies

Popular Products from Pyrotek

Popular Products from Pyrotek

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts