In these days of increased compliance in the building and construction industry, the spotlight is falling increasingly on the fire-retardant properties of building materials in general. The Grenfell Tower disaster in London highlighted the issue of fire-retardant cladding materials but increasingly the focus is also on non-exterior building materials. These can include interior wall and ceiling linings as well as materials used in internal commercial fit-outs and general fabrication.

For many years IPS has been selling its Ezyliner polypropylene wall and ceiling substrate into many different areas such as cool rooms, laboratories, freezing works and most significantly into the mining industry both in NZ and overseas. Originally the requirement was for a smooth, hardwearing, easy to clean product that was easy to install. Over time, however, the demand for a product that was also fire-retardant began to increase significantly. At the same time, IPS also had a specific request from a client for a fire-retardant polypropylene that was suitable for the construction of laboratory fume cabinets and other fabricated componentry.

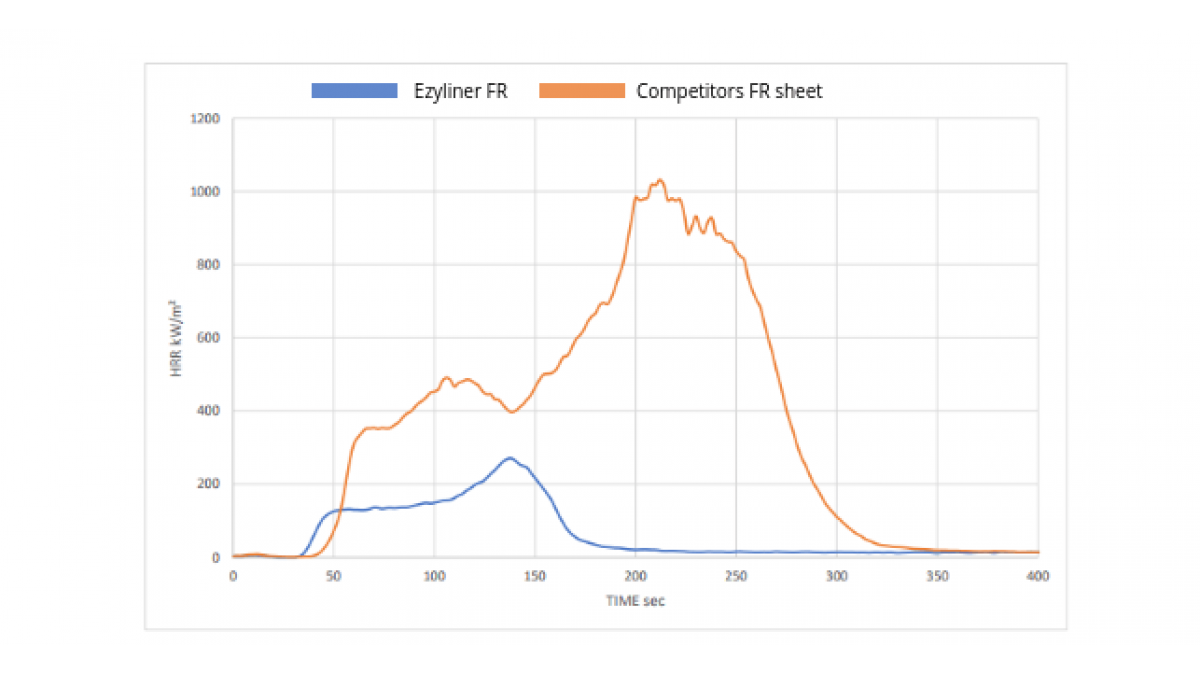

After significant research into both the NZ and Australian markets, IPS decided they required a material that in addition to being fire-retardant, was also suitable for general fabrication, welding and thermoforming. The fabrication qualities were easily tested, but the fire-retardant properties of the material needed to be tested in accordance with a particular standard. Further research indicated that testing in accordance with AS5637.1.2015 and ISO5660 would be appropriate, both for wall and ceiling linings as well as the construction of fume cabinets and other laboratory plants.

After working with a suitable manufacturer, IPS placed a small trial order and testing was conducted at the BRANZ facility in Wellington. The key aspects of the testing were heat release, smoke production and mass loss. Samples of IPS fire-retardant material were tested in tandem with standard polypropylene as a point of reference so that significant differences in performance could be detected. After extensive testing proved the superior fire retardance of the new material over standard polypropylene, Ezyliner FR was finally born. Tested in accordance with the standards mentioned above, Ezyliner FR achieved a Group 3 fire classification.

At a price point that is only slightly above that of standard Ezyliner, the FR grade has now become the material of choice in many industrial wall lining installations. The material has also proven its excellent fabrication qualities and is now being used extensively in a product that is exported throughout Australia and Asia. The material has an exceptionally smooth, clean surface and is masked on one side for extra protection prior to installation or fabrication. A sheet size of 2400 x 1200 x 3mm white is available ex-stock, but almost any size and thickness is available on indent. Indent quantities and colours other than white are subject to a strict minimum order quantity.

Copies of the BRANZ testing method and certification are available on request.

Case Studies

Case Studies

Popular Products from Mulford

Popular Products from Mulford

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts