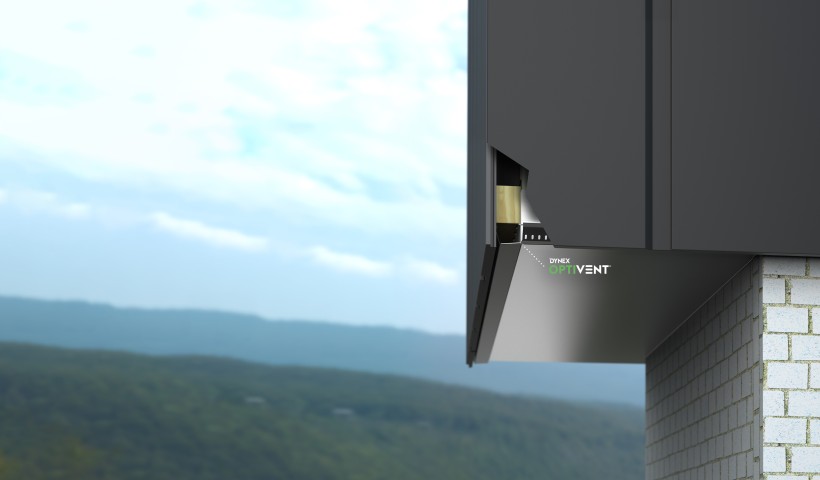

The team at DYNEXbuild has just developed a new range of Cavity Closers. This regularly requested product is also known as Vermin Strip, Vent Strip or Vented Cavity Vermin Strip. These products are used in association with a cavity in most building applications, and are compatible with Palliside's range of weatherboard systems.

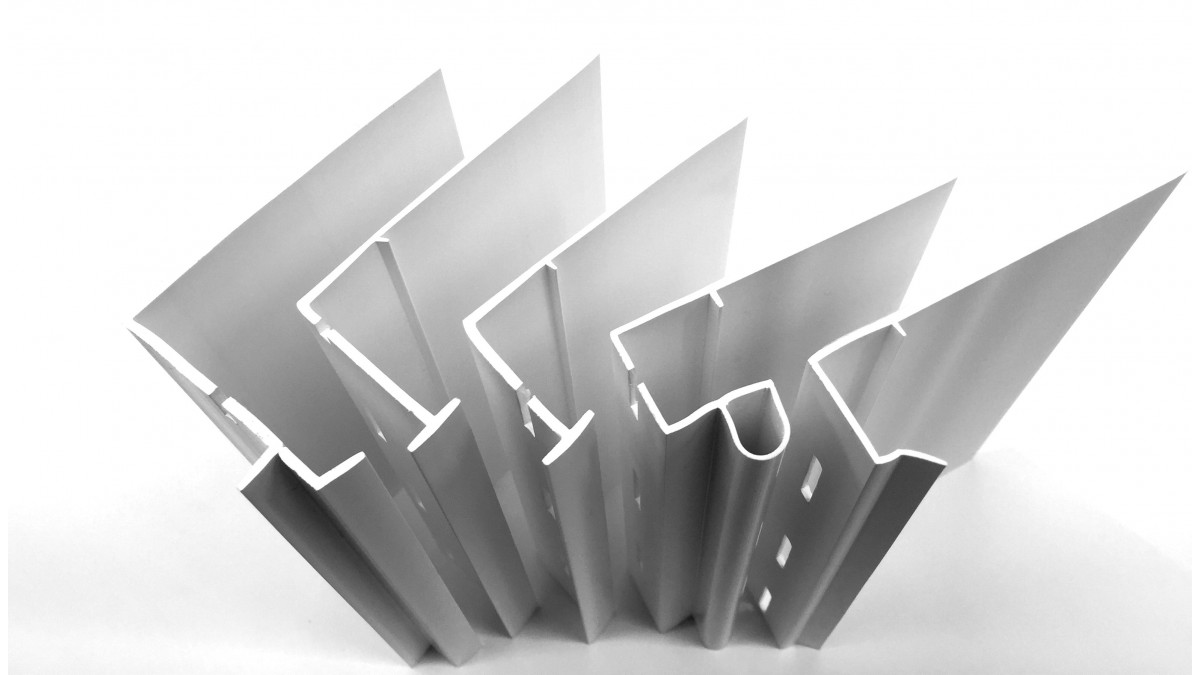

The team at DYNEXbuild has taken this relatively boring product and added some spice (innovation) to the mix. DYNEXbuild has added a cavity batten locator, tearaway strips, flexible tips and a unique bulb seal, all with the goal of making the product look better, but most importantly perform better than the competition.

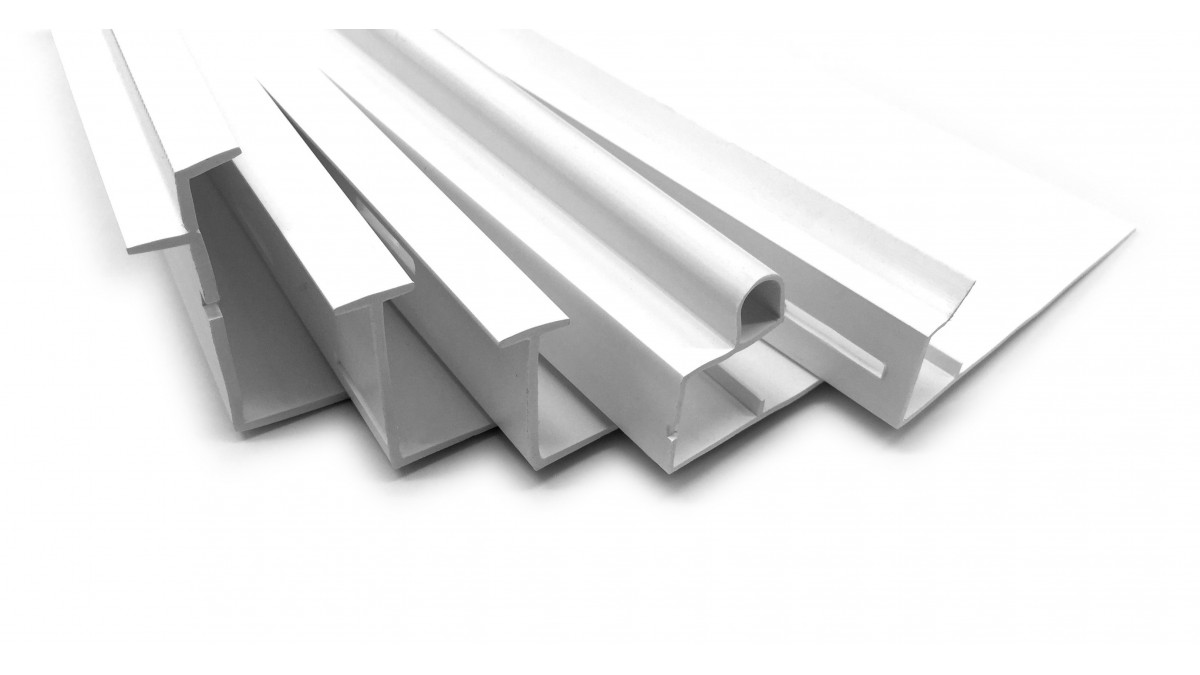

The five products in this range include:

- Raked Roof Closer

- 20mm Cavity Closer

- 30mm Cavity Closer

- 35mm Cavity Closer

- 40mm and 50mm Cavity closer

The Raked Roof Cavity Closer utilises a unique bulb design that allows the variable gap to be closed, meeting building code requirements. When trying to close up the variable gap created on an angled cut with weatherboards, this product's compressible bulb closes those gaps nicely. This feature will greatly enhance the vermin proofing on any raked roof design using weatherboards.

The 20mm Cavity Closer features a flexible seal that facilitates closing unsightly gaps created by variations in cavity thickness.

The 30mm and 35mm Cavity Closers have a built in cant strip, and as they are manufactured thicker and stronger than others, they won’t crush when the timber weatherboards are secured.

The two-in-one Cavity Closer allows a 50mm Closer to be reduced down to a 40mm Closer by cutting off the 10mm tearaway strip.

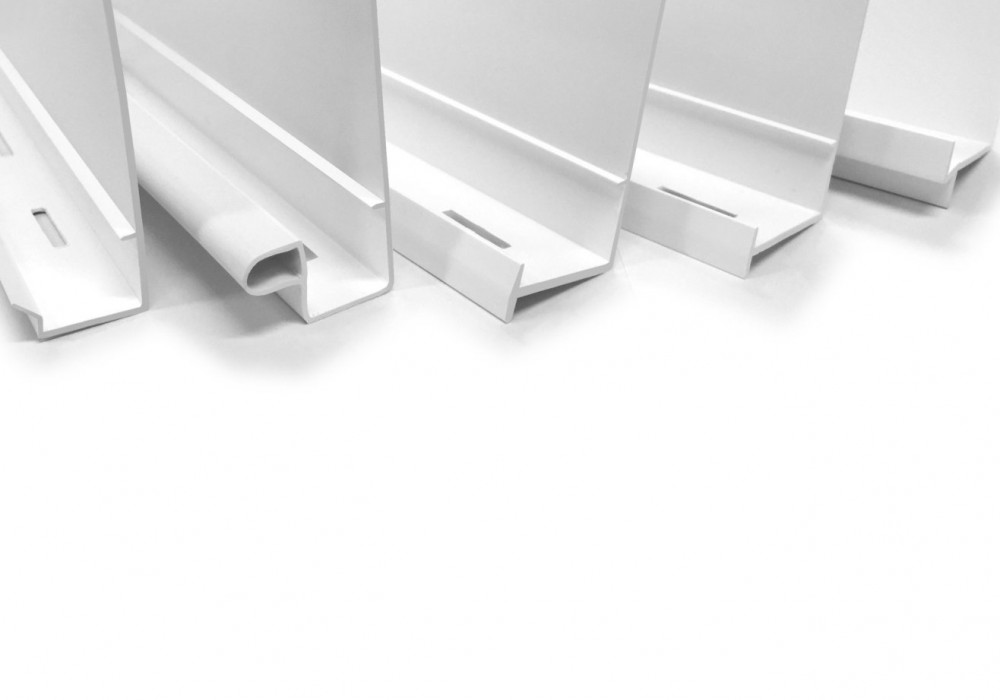

With the development of these innovative new products, the team at DYNEXbuild has uncovered some essential skills. With this knowledge the DYNEXbuild Development team has the ability to easily create any Cavity Closer for any given application. For unique designs or system requirements, please contact the helpful customer service team who will be able to develop a solution rapidly.

These products are all made in New Zealand using a high quality UV stabilised uPVC that is 100% recyclable. This range of products has all been BRANZ appraised and meet the requirements of NZBC Acceptable Solution E2/AS1, so designers can specify with confidence.

Case Studies

Case Studies

Popular Products from Dynex

Popular Products from Dynex

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts