With the Kingspan KoolDuct System, ventilation air flows over aluminium surfaces and does not have contact with any material containing loose fibres, making it ideal for high specification projects.

A total of 1,400 square metres of the Kingspan KoolDuct System was specified and installed; the ease and speed at which KoolDuct can be installed and the convenience of manufacturing the system on site made it the most ideal form of ducting for this project where time was of the essence.

Whereas traditional sheetmetal ducting is more complex and needs to be vapour sealed and thermally insulated as a second operation, the lightweight but strong Kingspan KoolDuct System requires only a single fix installation. This not only makes it a high speed operation for projects when time is critical but also provides a considerable space saving advantage.

A recent independent analysis by highly respected consultants Bucknall Austin USA concluded that the System can be installed up to three times faster than sheet metal ductwork.

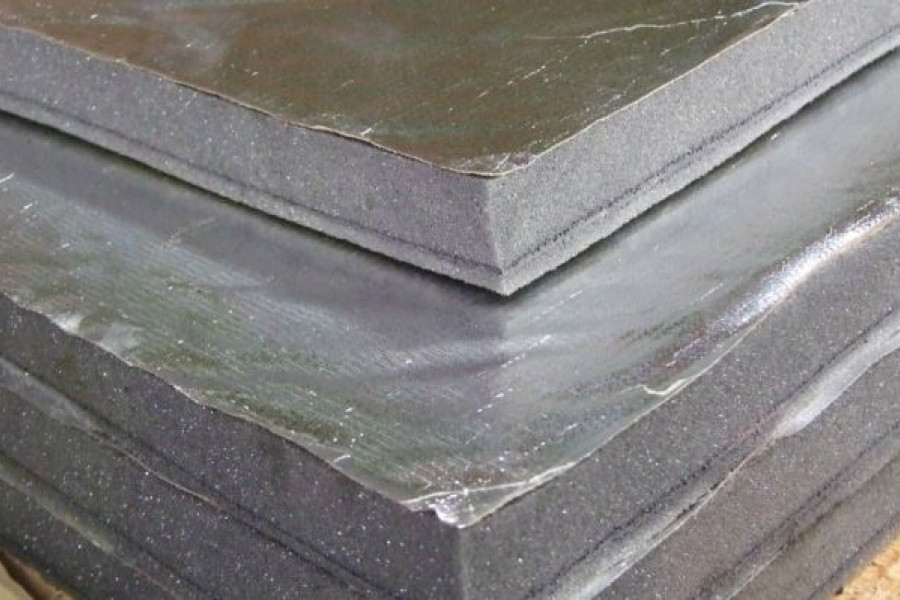

Kingspan KoolDuct is manufactured without the use of CFCs/HCFCs and has zero Ozone Depletion Potential (ODP). The rigid phenolic insulation panels are faced with reinforced aluminium foil on both sides, making the System very durable and also aesthetically pleasing in open to view applications.

Other benefits of ‘complete system technology’ enhance its appeal to specifiers. The system’s low level of air leakage and superior insulating properties can result in electrical consumption savings. Rigid phenolic insulation also offers several further advantages, including excellent fire resistance with negligible smoke emission and first class moisture resistance.

As part of Forman Building Systems Ltd’s commitment to combine product innovation with social responsibility, the Kingspan KoolDuct System is now also available in New Zealand. It has already been specified on several projects and has been installed in the ACC’s new building in Christchurch.

Case Studies

Case Studies

Popular Products from Comfortech Building Performance Solutions

Popular Products from Comfortech Building Performance Solutions

Posts by Comfortech Technical

Posts by Comfortech Technical Most Popular

Most Popular