There are a lot of design aspects that make the “Boat Shed House” in Lyttelton unique such as the externally insulated CLT walls that help this project achieve a 9 Homestar rating, but often it is the very small details, most often overlooked, that really help to make a home warm, dry and healthy.

Aluminium windows are by far the most commonly used window frame material in New Zealand and for very good reasons, the only downside is that aluminium is highly conductive. On an average build the window frames (excluding the glazed area) will make up less than 2% of the building's total envelope yet they are responsible for over 15% of a building's heat loss as well as exposing the building to a very high risk of internal surface condensation.

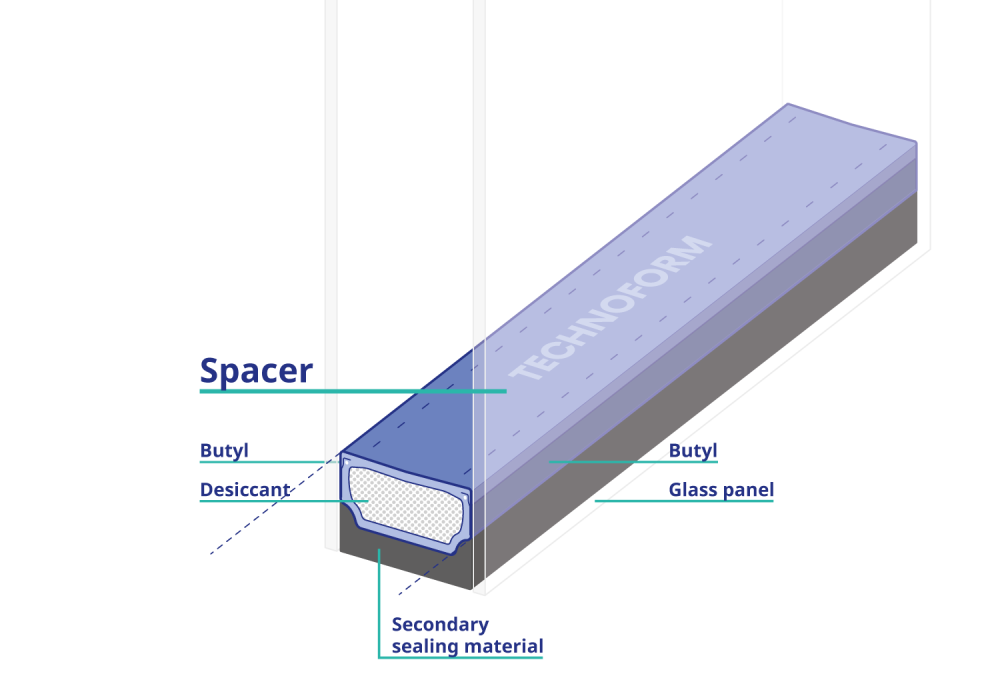

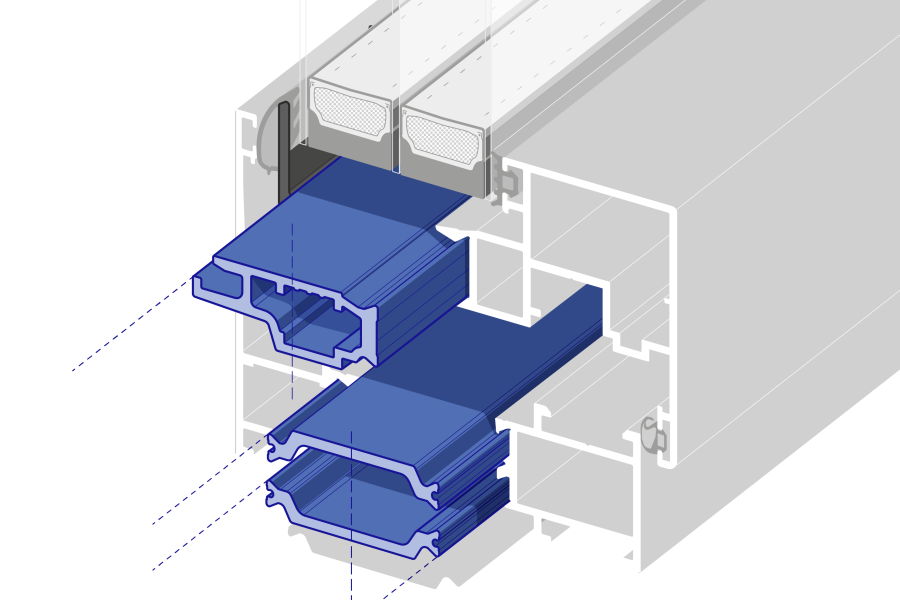

For these reasons, a thermal break supplied by Technoform and used in APL’s ThermalHEART Metro Series window suite was specified in this project. The polyamide thermal break extruded with glass fibre reinforcement thermally separates the aluminium window frame into an outside section and an internal section. This means that heat energy cannot flow easily to the outside in winter or to the inside in summer.

Another added benefit of using a thermal break is that it maintains a warm internal surface temperature in winter meaning that the risk of condensation is greatly reduced provided the relative humidity in the room is maintained at a comfortable level.

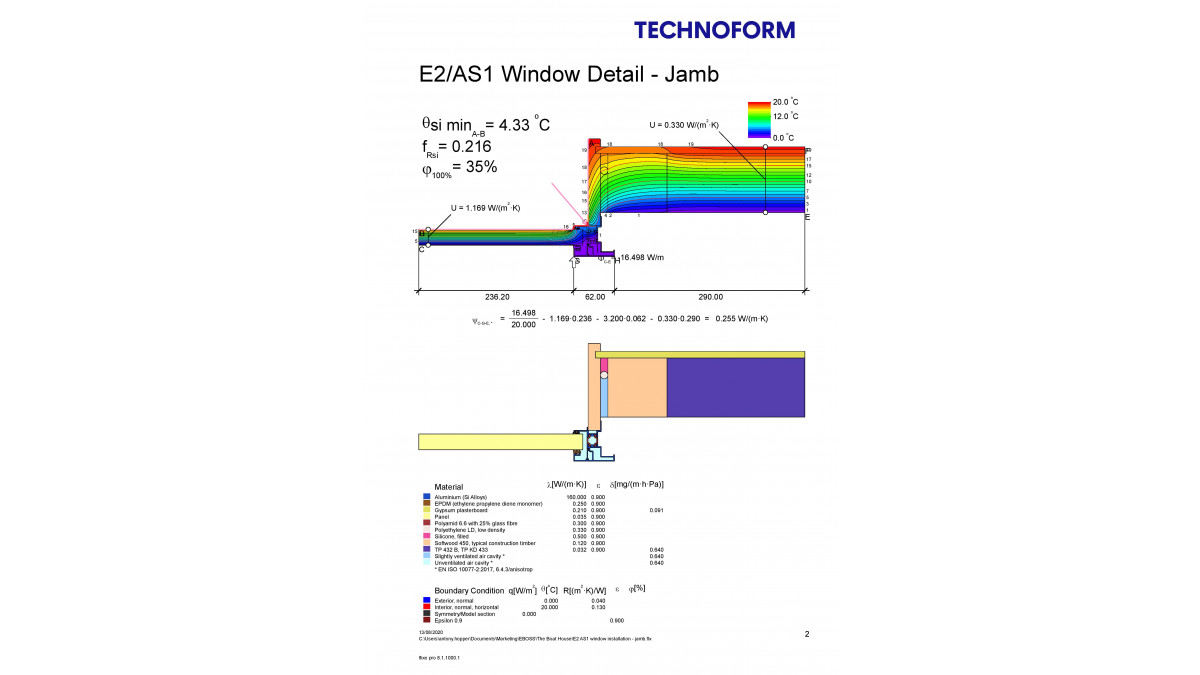

However, small details that are often overlooked can negate many of the positive benefits a thermally broken window offers to a home focused on energy efficiency. The biggest problem is with the way we install windows in New Zealand according to E2/AS1; in this situation the thermal break is situated in a ventilated cavity. Cold air can easily bypass the thermal break and will penetrate as far back as the window seal at the reveal.

A simple thermal analysis of the E2/AS1 detail shows that on a cool 0°C day in Christchurch you can expect an internal surface temperature of 4.3°C (high condensation risk) and a year-round reduction in thermal performance of the window of 10% to 25% depending on window size.

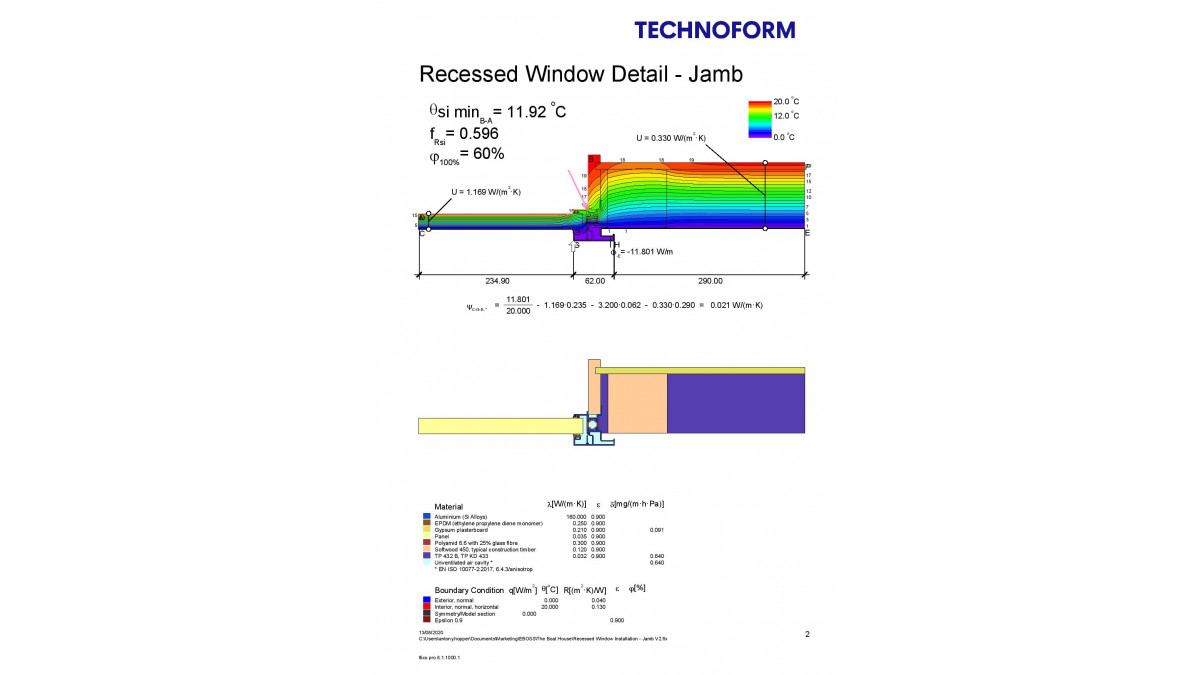

Thankfully the designer and owner of this project Julie Villard (Design Advisor at Christchurch City Council) knew of these issues and decided to recess the window back in line with the insulation layers instead of sitting it out in the ventilated cavity.

The thermal analysis of the recessed window detail shows that on the same 0°C day it is now possible to achieve an internal surface temperature of 11.9°C with an enhanced thermally performing window resulting in a warmer, drier and healthier home.

Please see the thermal analysis reports in the image gallery above for more details.

Case Studies

Case Studies

Popular Products from Technoform

Popular Products from Technoform

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts