NEW

NEW

There is a misconception that an appropriate fire rating level (FRL) can be achieved for the timber infill of rib and infill floor-ceiling systems by simply changing the timber infill from a Group 3 to a Group 1. Often a Group Number change is being used in place of an FRL, and although the timber is an integral part of the tested floor-ceiling system, the timber itself has no protection against fire.

The problem with this is that the ISO 9705 test used to determine a Group Number finishes when flash-over occurs — at the time a fire has taken hold. It is at this stage that an FRL is required, and an FRL is determined using AS 1530.4.

ISO 9705 vs. AS 1530.4

The requirements for internal surface finishes of ceilings, walls and floors are controlled by the NZBC because certain types of finishes (e.g. wood and wood products) have been found to contribute significantly to an increase in fire hazard.

The ISO 9705 test involves a small bedroom-sized room lined with the test material on the walls and ceiling. A gas burner — representing a burning wastepaper basket — is placed in a corner very close to the wall surfaces.

In the 20-minute test, the gas burner provides 100 kW output for 10 minutes and then 300 kW for the second 10 minutes. The time at which the room reaches flash-over or full room involvement — defined as exceeding 1000 kW for this test scenario — determines the Group Number.

Changing the Group Number does not change the fire rating of a system as ISO 9705 is only used to determine when an interior finish/material will flash over.

The NZBC requires floor-ceiling systems to be tested using AS 1530.4, section 4 to determine the FRL.

A tested solution for fire rating timber infill

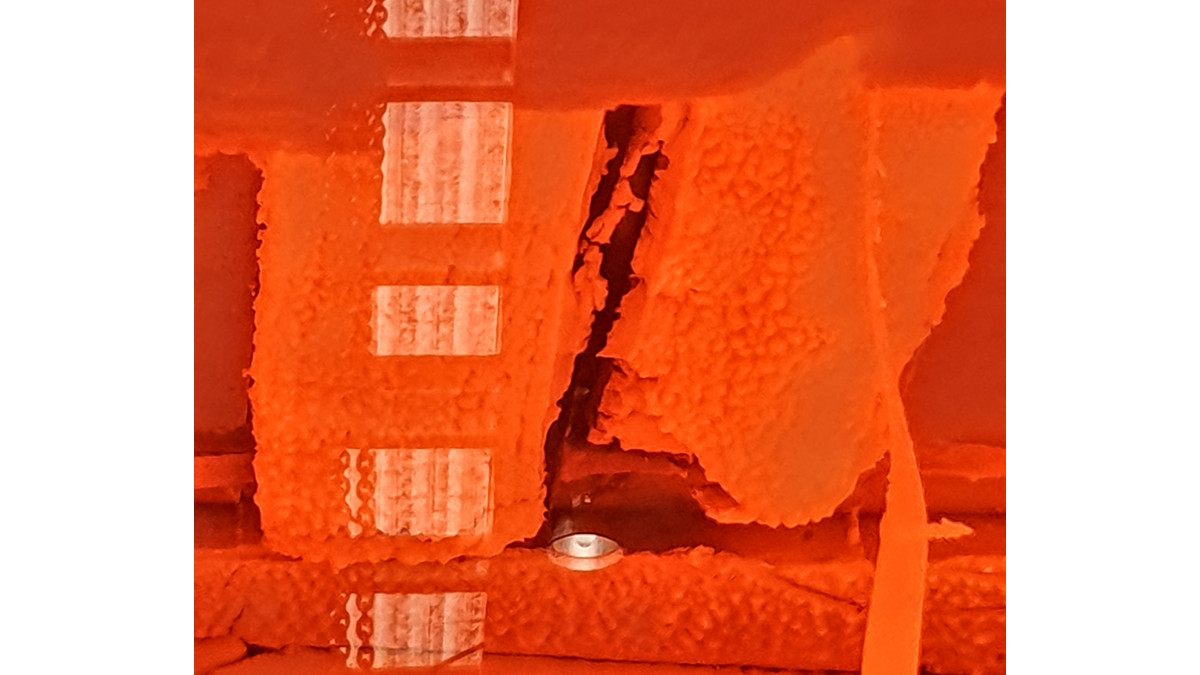

Tech Coatings conducted two tests at PFITS using AS 1530.4:2014 to determine the FRL of a floor-ceiling system with the addition of FBL-100 Multiple Substrate Intumescent Coating System:

- The first specimen was nominally 1400 x 1400mm of 25mm rough sawn pine topped with 75mm reinforced concrete. The timber was coated with 300µm of FBL-100, the DFT (dry film thickness) needed to change the Group Number to a 2-S. This system achieves an FRL of –/120/90

- The second specimen was nominally 1400 x 1400mm of 25mm rough sawn radiata pine topped with 75mm reinforced concrete. The timber was coated with 1000µm of FBL-100, the DFT used in other timber solutions. This system achieves an FRL of –120/120

Tech Coatings now offers two tested solutions, supported by endorsed reports, for the timber infill of concrete rib and infill floor-ceilings.

Case Studies

Case Studies

Popular Products from Tech Coatings

Popular Products from Tech Coatings

Posts by Shane Wyatt

Posts by Shane Wyatt

Most Popular

Most Popular