The new $21million student accommodation village at Otago Polytechnic has been designed to cater to the tertiary institute’s growing number of domestic and international students. The building has a 6,500m² floor plate, which houses four and five level facilities with a capacity for up to 231 beds.

Sustainability was key in the building’s design; it is the largest timber framed building in New Zealand (by volume and height) and only FSC certified timber has been specified for the build. In addition, the designers looked to create a healthy building, with a focus on energy, water and waste conservation.

“We were looking to achieve an environmentally sustainable building, particularly in regards to heat loss,” explains Sam Cadden, Project Manager, Logic Group. “We wanted to reduce the amount of heat used within the building. That’s why we went for a highly efficient envelope on the building.”

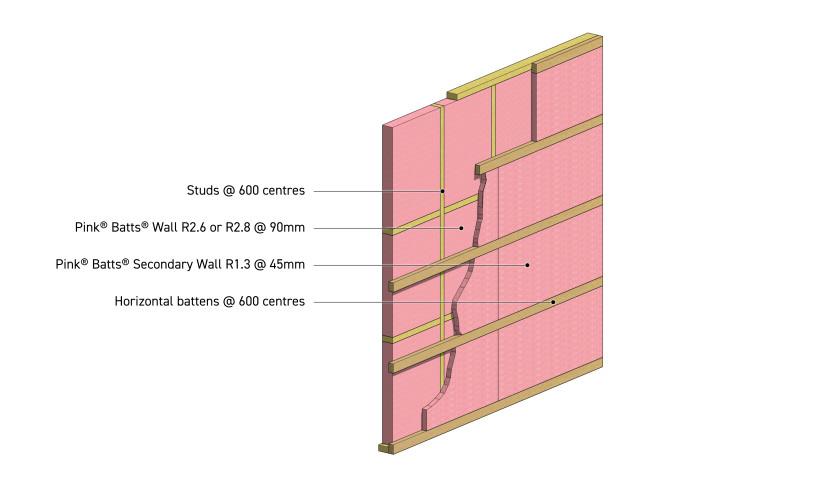

This highly efficient envelope was formed using three complementary products — an internal airtightness membrane, Pink Batts insulation, and a rigid air barrier. “These components all work together to form a system that makes the building very efficient,” says Cadden.

“Initially, we weren’t using Pink Batts, but we found that we couldn’t achieve the R-value required with the other products, and there were also issues with moisture control. That’s why we switched to the Pink Batts.”

In total over 2,000 bales of Pink Batts were specified and installed for the project. This included over 1,000 bales of Pink Batts R4.0 Ultra Ceiling insulation and over 500 bales of Pink Batt R3.2 Ultra Wall insulation — providing exceptional R-values for the building. Pink Batts R1.2 Masonry and R1.8 and R2.4 Wall Insulation were also used for different areas of the building.

With the project set to be completed in February 2018 and the Pink Batts now installed, Cadden is happy with the progress. “It’s warm and it’s quiet — no noise gets in from the outside,” he says. “We’ve exceeded the thermal building standards exponentially.”

Case Studies

Case Studies

Popular Products from Comfortech Building Performance Solutions

Popular Products from Comfortech Building Performance Solutions

Posts by Comfortech Technical

Posts by Comfortech Technical Most Popular

Most Popular