With sweeping views and an exposed ridgeline location, Hamilton designer Noel Jessop wanted a cost-effective way to protect the framing of this imposing new build.

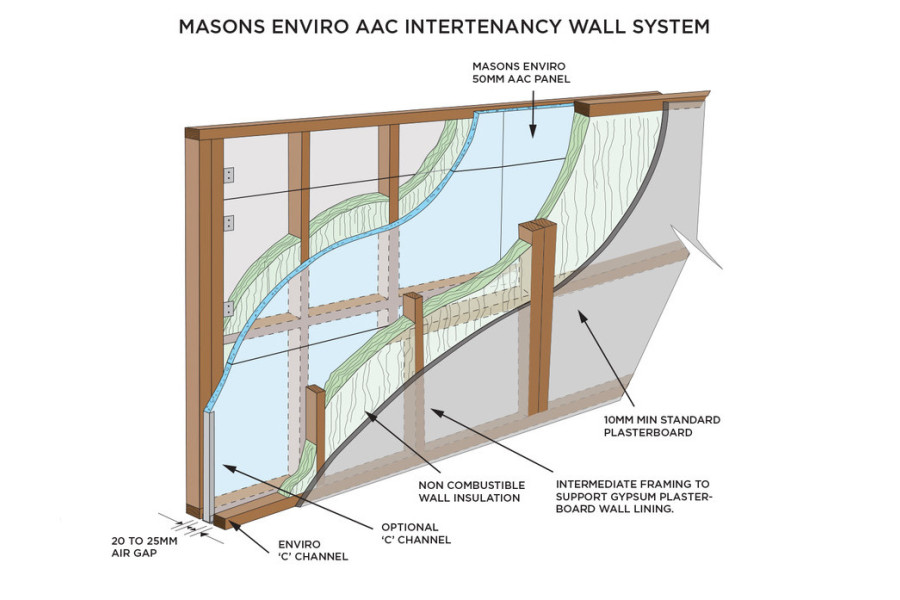

The wall assembly on this project calls for a water-repellent breathable drainage plane over timber frames, a cavity created with timber battens followed by compressed fibre cement sheet with negative detailing and finally a cedar rain screen. This complex build on an exposed site needed a weather-air barrier that could handle the elements on-site, was simple to use and would perform well both during the build period and for the life of the structure.

The UNI Flexible Air Barrier system was specified to provide a tough, resilient, highly water-resistant yet breathable weather barrier during the build and over the life of the structure. When installed with 40 below flashing tape and UNI cap nails, air and moisture are effectively excluded from the framing and insulation.

‘’Now seeing the product on-site, and having watched how this has been installed, I’m super impressed with the quality of the product, how UNI is easily installed and how its holding up to quite a wet and windy winter," says Noel Jessop, Principal, Noel Jessop Architecture.

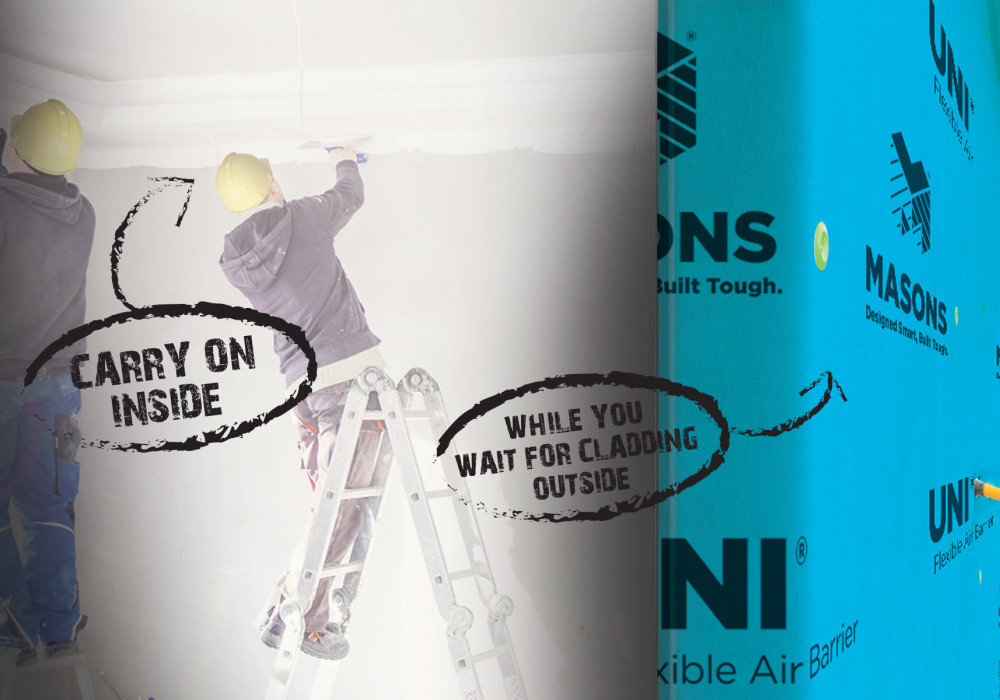

UNI is a proprietary system that offers temporary weather protection for up to 90 days. This allows interior works including lining and insulation to proceed without the exterior cladding in place. The system installs quickly with a minimum of components and offers a choice of fixing methods. It is suitable for all wind zones including Very High, with Extra high wind zones also possible with a specific fixing method.*

"UNI has been the perfect saviour for this project," says Joel. "There have been no delays due to weather and the builders and sub-trades have been able to proceed without any interruptions to the project. Seeing how well UNI has held up the wind has also impressed me — any other product wouldn’t have had this result."

Builder, Hayden Johnstone, had this to say: “We found the product easy to install and with the addition of 40 Below tape on the joins, UNI has prevented the ingress of water during a winter build. On the really wet days, it's great to have the option to continue working on the inside of the building without having to finish the exterior cladding. Dry builders are happy builders."

The UNI flexible air barrier system has a current CodeMark certificate for added assurance.

*In extra high wind zones only a specific fixing method must be used. This falls outside of the current CodeMark and is an alternative solution.

Thanks to Noel Jessop Architecture and Johnstone Building ([email protected])

Case Studies

Case Studies

Popular Products from Masons

Popular Products from Masons

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts