The idea of a new house build embracing Litecrete lightweight precast concrete and recycled materials might seem somewhat incongruous on paper. In execution, however, the results of this particular new build, sympathetic to the implementation of recycled materials throughout, is simply stunning.

The house doubles as a race car workshop. Sited adjacent to the Hampton Downs Race Park, the house walls were constructed using 220mm thick Litecrete precast panels, many with black oxide colouring. The 220mm thickness has in-built insulation which complies with the Building Code H1 requirements.

Manufacturers, Wilco Precast, concocted a release agent to achieve the required "derelict" surface colouring to the exterior of the concrete panels. A weatherboard precast finish was also featured on the south facade panels while a band-sawn timber finish was used on some of the internal concrete surfaces.

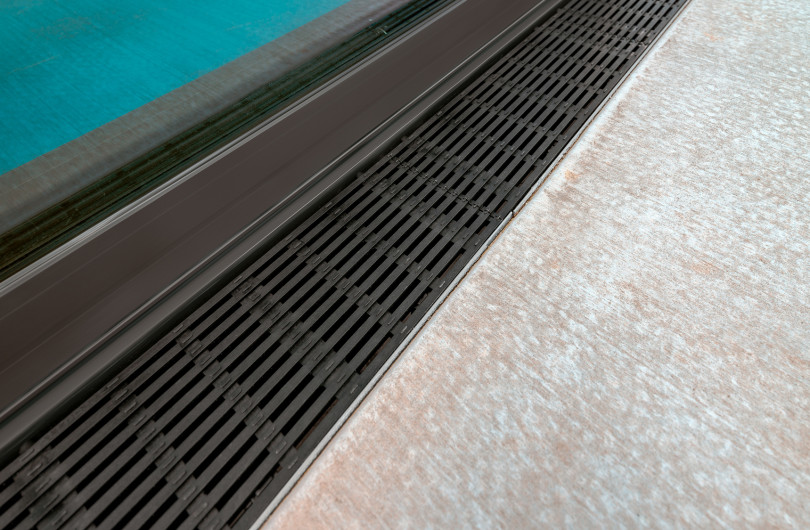

The home features open plan living, framed by a three-bay workshop space at one end and an elegant large-scale covered outdoor area at the other, accessed by glass and aluminium sliding doors. The glass extends to the full height of the roof, letting in masses of light and showcasing a recycled brick dividing wall that is so perfectly imperfect as to look as if it has been lifted wholesale from an early 1900s Otago wool store.

The sleeping space includes a separate master bedroom as well as an all-important dormitory room for the race crew.

Designed by the owners in conjunction with Mark Rantin from MRA Limited, the house was built by Mainline Construction. The attention to detail is impressive and it is the small details which stand out; copper plumbing fixed to the walls; industrial factory light shades; rustic benches and tables and a classic Kiwi polished-pine radiogram in the lounge.

The materials used throughout the building have come from far and wide. The trusses, made of Australian hardwood and sourced from a demolished wharf were re-manufactured for the project in Clyde; the refurbished heavy-duty internal roller door mechanisms are originally from an old barn in the United States via Masterton; the kauri sarking in the ceiling and the heritage fire surround came courtesy of Ward Demolition.

Who said the old and the new don't work?

Case Studies

Case Studies

Popular Products from Litecrete

Popular Products from Litecrete

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts