NEW

NEW

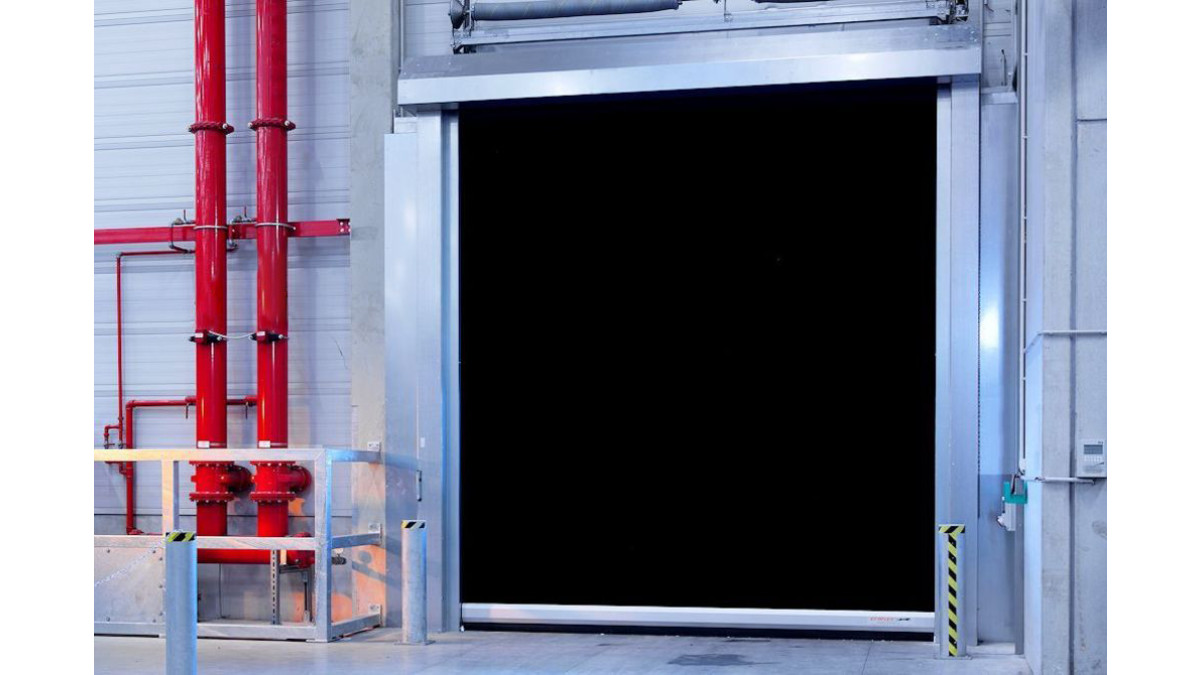

With increasing compliance demands in hazardous industrial environments, ensuring safety, high performance, and installation efficiency has never been more critical. Efaflex’s EX Series doors combine ATEX-certified engineering with high-speed operation, delivering a robust solution for explosion risk zones — designed to work seamlessly across both new and existing infrastructures.

Built for high-risk environments

Industries such as pharmaceuticals, petrochemicals, food processing, and manufacturing face constant exposure to explosive atmospheres. The Efaflex EX Series, including the EFA-SST-L EX (spiral door) and EFA-SRT-EX (roll-up door) is purpose-built to meet these challenges. Both models comply with the ATEX Directive 2014/34/EU and are approved for use in gas explosion protection Zones 1 and 2, and dust Zones 21 and 22.

Self-supporting and intrinsically safe

Engineered for permanent industrial applications, the EX Series features a self-supporting structure and intrinsically safe components. This design allows for integration into existing facilities without the need for significant structural alterations, supporting upgrades and extensions with minimal planning complexity.

Explosion protection by design

Each aspect of the EX Series has been carefully engineered to perform safely in hazardous zones. Safety light barriers, contact edges, and emergency stop systems are all explosion-proof. The door’s control system is housed outside the hazardous zone in an IP65-rated steel cabinet which includes a microprocessor with integrated frequency converter. All electrical components are ATEX certified, and the mechanical systems are adapted to their intended zone classification.

Quiet, fast and durable operation

With opening speeds of up to 1.0 m/s and closing speeds of 0.5 m/s, the EX Series doors minimise air exchange and exposure times between critical zones. The EFA-SST-L EX offers contactless spiral-guided motion for silent, wear-free operation, while the EFA-SRT-EX utilises tensioned guides for stability and wind resistance. Optional transparent infill panels and anodised aluminium finishes provide flexibility to meet site-specific needs.

Smart installation, smart compliance

Delivered pre-engineered with precision-fitted components, Efaflex doors require minimal onsite configuration. The doors meet rigorous EN standards, including EN 12426 (air permeability, Class 2) and EN 12424 (wind load resistance, up to Class 4) easing the compliance process for designers and facility managers.

Project support from design to delivery

Efaflex offers comprehensive support across every project phase. From initial specification and compliance guidance to installation support, architects and engineers have access to complete technical documentation, BIM assets, and local expertise to ensure alignment with New Zealand Building Code requirements and project goals.

Case Studies

Case Studies

Popular Products from EFAFLEX

Popular Products from EFAFLEX

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts