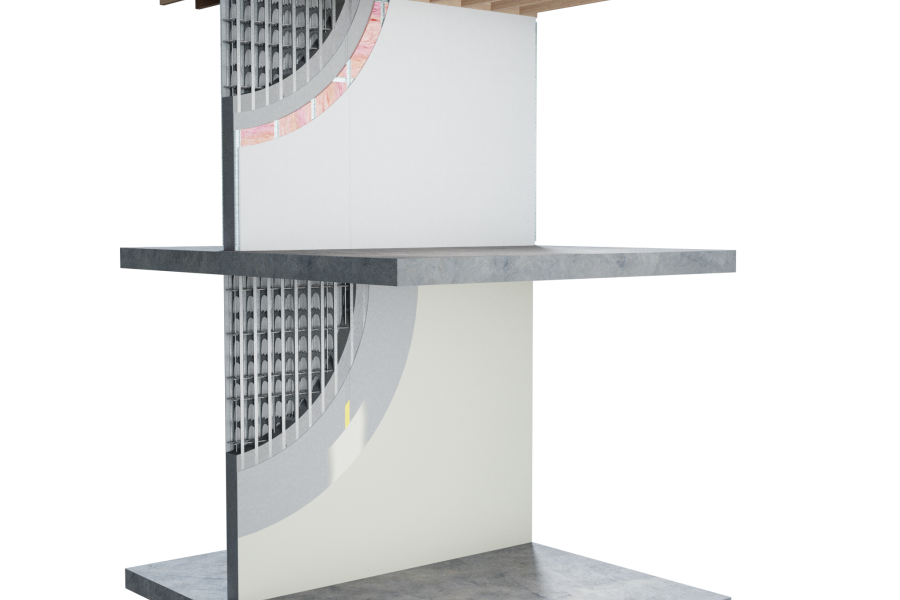

AFS Rediwall is a smart alternative to blockwork that can help keep projects on track. The system is ideal for basement and retaining walls in apartments, retirement villages and high-end residential projects. The light weight of Rediwall’s components also makes it an excellent solution for buildings on tight or sloping sites where access can be difficult.

Here’s a look at how Rediwall can help you save time on site:

Fast and easy installation

Rediwall is over two times faster to install than traditional blockwork construction due to its modular installation method. The lightweight PVC formwork is manufactured offsite by AFS, and delivered to site ready for install. On site, the panels simply clip or slide into place, and are then braced and core filled to provide a robust basement or retaining wall in less than half the time required for blockwork.

Reduces trades on site

The Rediwall system is lightweight and easy to handle, and can be installed by the builders on site — meaning one less trade on site.

Ensures greater control over the build programme

With no risk of delays while waiting for the blocklayer subtrade, Rediwall gives builders more control over the construction programme. The AFS team works closely with the design and construction team right from the start of the design process to factor in project timelines and ensure that the Rediwall components are delivered to site right when they’re needed.

A proven time-saving solution

Rediwall has brought time savings to hundreds of projects throughout New Zealand. Recently AFS has been involved in a large development for the Huapai Country Club, where Rediwall was specified for structural load-bearing basement walls. Over 450m² of Rediwall was erected, reinforced and corefilled in just three weeks — saving significant time over less efficient blockwork methods, and keeping the project on track.

Learn more

To learn how Rediwall can bring greater efficiency to your projects, get in touch with AFS.

Case Studies

Case Studies

Popular Products from AFS New Zealand

Popular Products from AFS New Zealand

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts