Woodspan PLT Midfloors are an efficient solution ideal for terraced housing, apartments and other multi-residential projects. Prefabricated off-site using advanced CNC technology, the midfloors are fast and easy to install, ensuring excellent time savings on site. By manufacturing the panels locally from 100% NZ radiata pine, Woodspan has excellent control of their supply, resulting in reliable lead times and improved project efficiency.

How can PLT Midfloors improve design efficiency?

Woodspan PLT midfloors bring improved efficiency through their excellent spanning capability and height savings. “As the grain runs in one direction, the midfloor panels can achieve wide spans up to 4340mm,” explains Jared Wilson, Sales Manager, Woodspan. “And the panels also bring advantages in terms of height savings, with our PLT midfloors not requiring the same depth as a traditional joist system.” A Woodspan PLT midfloor or roof can save significant height in a multi-level build — ideal for projects with restrictions around overall height, such as when daylight envelope rules are a limitation.

How can PLT Midfloors reduce time on site?

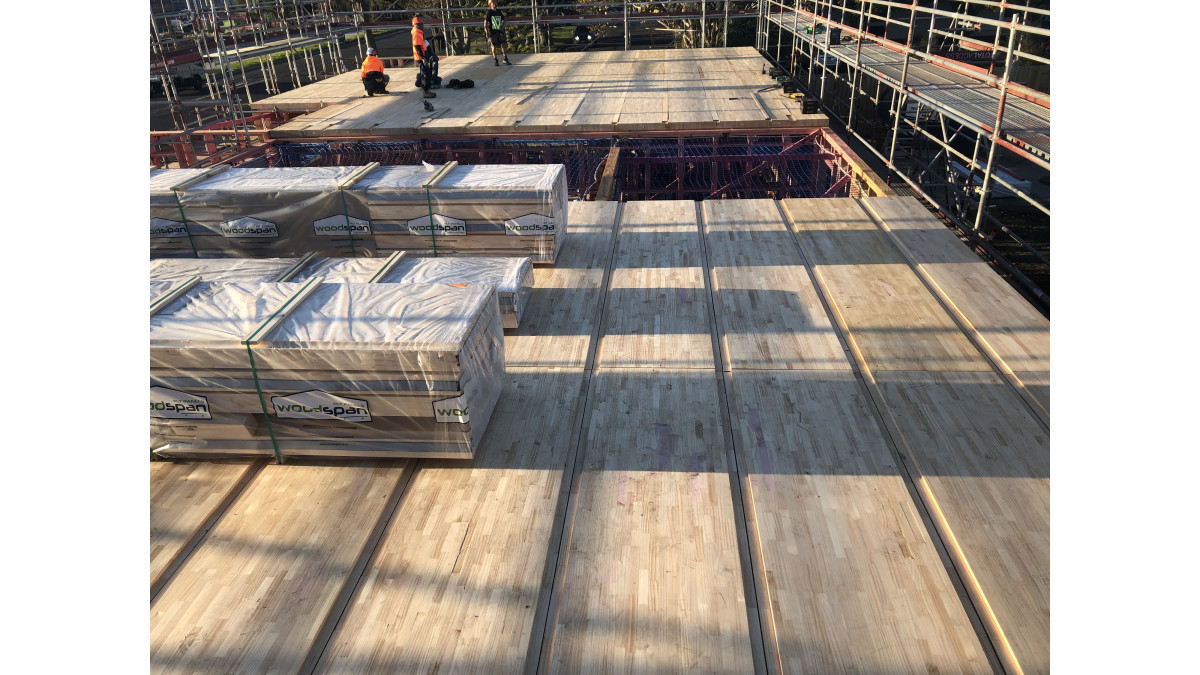

Woodspan PLT Midfloors save time and labour on site by eliminating the measuring, cutting and fixing involved in traditional midfloors. “Our systems are a far less labour-intensive way of installing a structural floor,” says Jared. “Panels arrive on site packaged up in order of install, so for builders it’s as simple as dropping them in place and screwing them down.”

The simplicity of the system can significantly reduce the time involved in installing midfloors. On a recent three-level apartment project in Auckland, a 288m² midfloor was installed in just over a day with a team of six. And on another project — the extension of an eight-unit hotel in New Plymouth — a 171m² midfloor was installed in just one day with only three builders on site.

How does Woodspan help reduce waste?

Precise manufacturing by the Woodspan team means very little waste on site, with no offcuts or excess product. The use of 100% NZ radiata pine from sustainably managed forests also reduces transport emissions and further minimises the environmental footprint of the panels.

How does Woodspan keep their lead times low?

Woodspan engages with architects early in the design stage, assisting with design and panel layout to ensure a smooth specification process. This involvement early in the project means they are able to build lead times into their manufacturing process so panels are delivered right when they’re needed on site.

Talk to Woodspan to learn how their PLT Midfloor systems can improve efficiency on your project.

Case Studies

Case Studies

Popular Products from Woodspan

Popular Products from Woodspan

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts