Passive fire protection involves the use of fire-resistant construction elements or barriers within a building to create fire separated “compartments”. Compartmentation in this way acts to contain or delay the spread of fire to other parts of the building, allowing time for the safe exit of occupants, and preventing the spread of fire between buildings.

A fire-resistant construction element is classified by a Fire Resistance Rating (FRR), determined by a Fire Endurance Test, with the result given as duration. An FRR will be shown in the format of 30/30/30 through to 240/240/240, where the numbers represent the minutes for which the element can withstand the following tests when subject to a standardised heating regime from AS1530.4:

- Resists collapse — Structural Adequacy

- Resists passage of flames and hot gases passing from the fire exposed side to the unexposed side — Integrity

- Limits the transfer of heat from the fire exposed side to the unexposed side — Insulation

As an example, an element with an FRR of 90/60/30 will resist collapse for 90 minutes, not allow any cracks or opening to form for 60 minutes and will limit heat transfer for 30 minutes.

When electrical, plumbing and ducting need to pass through these fire-resistant barriers, the fire resistance of the barrier is compromised, and the FRR needs to be restored. For ductwork, the NZBC in clauses C/ AS2-6 describes that any duct that passes through a fire separating element such as a wall or a floor, shall not reduce the fire resistance of the construction through which the duct passes. To achieve this, the NZBC references the use of either Fire Dampers, which close off the duct during a fire, or a Fire Resistant Enclosing Construction of the duct to effectively extend the fire compartment around the duct, and restore the FRR.

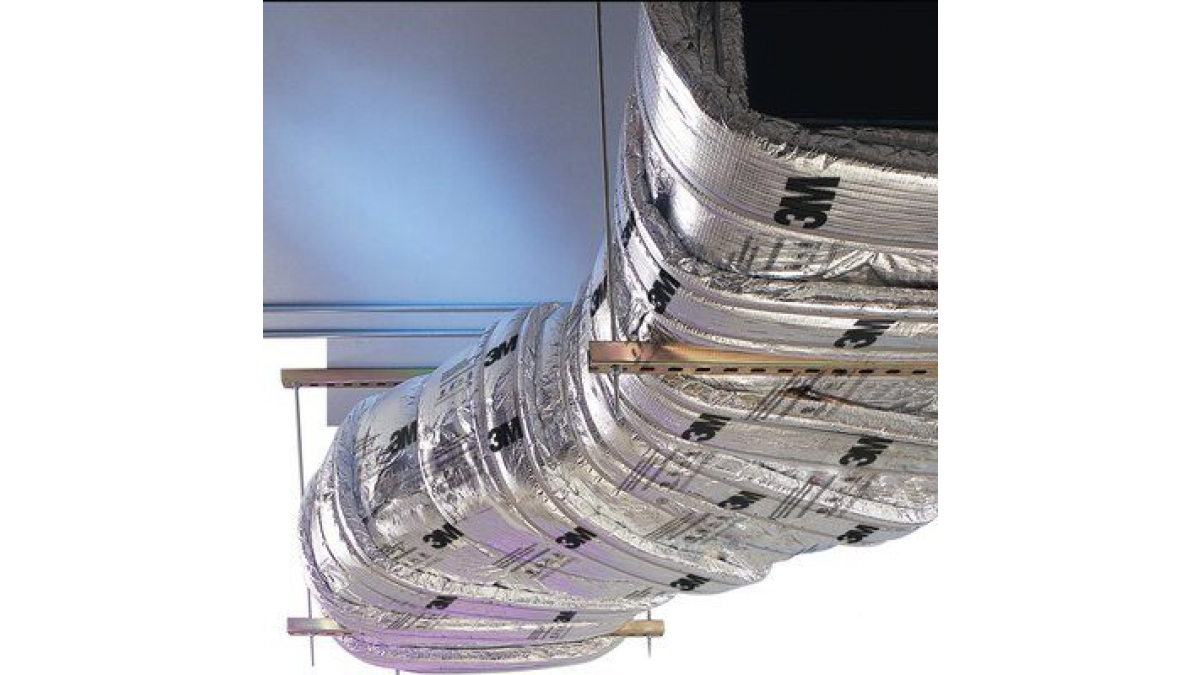

In some applications, fire dampers cannot be used to restore fire separation as described in AS/NS1668.1, due to potentially interfering with normal duct operation (eg. commercial Kitchen exhausts), or the duct must continue to operate and not “close off” during a fire (eg. zone pressurisation and smoke exhaust systems). The continued effective operation of smoke exhaust systems during a fire is particularly important for buildings such as convention centres, high-rise buildings and healthcare facilities, where compartment tenability must be maintained to allow safe egress of large numbers of occupants. For these applications, fire-resistant enclosing construction with 3M Fire Barrier Duct Wrap 615+ provides a clean, simple, lightweight and tested method of restoring the fire separation of compartments and protecting the ductwork from collapse or failure.

3M Fire Barrier Duct Wrap 615+ is manufactured with a man-made vitreous spun bio-soluble fibre, which provides low thermal transfer properties in a lightweight, low-profile, easy to apply product. The insulative properties of this wrap help keep heat, fire and smoke contained.

3M Fire Barrier Duct Wrap 615+ has been tested to AS1530.4 and can restore the FRR of fire resistant walls and floors penetrated by ducting up to 120/120/120.

Case Studies

Case Studies

Popular Products from 3M

Popular Products from 3M

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts