The construction industry, like almost no other industry sector, is responsible for a substantial negative impact on our environment: It is the biggest consumer of raw materials worldwide and produces massive amounts of waste.

Even though energy efficiency, CO2 savings and the use of renewable energies are now widely accepted as standard criteria for the construction of new buildings, in regard to the overall challenge the sector is facing, these measures are far from sufficient.

Many current building products still contain harmful substances. This is not only preventing these materials from being recyclable, but it also has a considerable negative impact on the quality of living, as we spend up to 90% of our time indoors.

We want to use passive fire protection as an example as passive fire solutions in general, and in particular intumescent coatings, have historically been known to negatively contribute to this issue — being comprised of countless harmful substances. Intumescent coatings were, per definition, the opposite of eco-friendly: toxic, foul smelling and carcinogenic.

Even though widely unrecognised, a lot has changed over the past decade and the new generation of intumescent coatings have grown up to the needs of today: being waterborne, halogen free and having low VOC.

We wanted to challenge ourselves and went on a quest to determine if we could achieve an environmental rating for a modern-day intumescent coating that would satisfy the rigid rules of an eco-label.

After all we thought: “If an intumescent coating could get an eco-label, so could every other building product.”

Eco-labels: Does green = green?

A certification would allow anyone to convert their internal approach and commitment to eco-friendliness into a shared, transparent, and standardised system. But the question arises: “Does green = green?”

Part of the answer somewhat unexpectedly presents itself in lists of countless eco-labels which exist around the world. Even if we narrow it down to New Zealand, companies can still choose from at least 39 eco-labels, and if narrowed down further to the certification of building products you still have up to six eco-certifications to choose from.

Many certifications base their process on a Life Cycle Assessment (LCA, ISO 14040) which evaluates the environmental aspects and potential impacts throughout the product’s life stages: from extraction of raw materials all the way through to their disposal.

All of these labels consider highly comparable environmental attributes which include toxicity, air quality, energy use, recyclability, VOCs, carcinogens, reducing water consumption, protecting waterways, use of sustainable materials and minimising material usage.

Despite these two factors, the certifications vary widely in their actual scope. Some are restricted to certain products, some focus only on a part of the Life Cycle (e.g., the production process), others widen their approach far beyond.

These broader approaches incorporate every aspect of the company such as general governance and the employees’ health, some even go beyond the boundaries that define a company and include the ecological impact on communities within the company’s reach.

If we take the above as a measure for the answer to our question, we must conclude that Green ≠ Green as the certification schemes vary too widely in their approach.

Which opens a further question, how do we choose the right certification for a company that is producing liquid fire protection?

Finding the right fit

Without a doubt it is essential to gain a sound understanding of what the specific certification offers, however, this understanding is only part of the equation.

Maybe even more importantly you need to understand your own motivation, sustainability goals and your commitment to environmental responsibility, if you want the eco-label you choose to truly represent your company’s values.

When engaging in this process your company has the opportunity to dive deep into their motivation, values and aligning goals. This can give you a chance to, eg. discover social challenges associated with environmental aspects you might not have been aware of.

The process that is triggered by this assessment offers consequently much more than a mere tool of analysis; it has the potential to become a highly educational exercise for every company.

This way the original assessment turns into a vehicle for creating a beneficial solution, offering new pathways and ways of thinking.

Environmental leadership

Every company should aim for making their impact on the community and the environment a measurement of their success.

Companies that are already incorporating environmental stewardship into their way of thinking are operating on a triple bottom line: profit, planet, people.

- Profit: Building a strong economy without harming the environment

- Planet: Reducing/eliminating the ecological footprint with transparent and ethical sourcing of raw materials, environmentally friendly practices in manufacturing, packaging and shipping, and diverting landfill waste at the end of the product’s life

- People: Social responsibility which is extending all the way to social fairness for the people aligned with economic processes e.g. employees, workers, suppliers

This ensures a thriving economy whilst integrating environmental consciousness into every aspect of these company’s identities. Often these companies are working to completely alter the landscape of the role that businesses play when protecting the Earth.

Benefits of going green

Besides the obvious ethical reasons there are many other benefits for companies that are willing to change their operating practices towards more environmentally friendly goals.

- Savings on utility costs through reduced energy consumption and increasing energy efficiency.

- Recycling reduces the strain on natural resources, creates less landfill, and is more energy efficient than extracting new materials.

- Environmental conscious practices can improve the brand image and deliver a clear competitive advantage in comparison to other players in the market

- Consumers are increasingly seeking to engage with eco-friendly companies and are willing to pay a premium for products that align with their values.

- Government policies increasingly recognise the environmental demands and are more stringent. The adaptation of more sustainable ways allows your business to easily comply with future governmental regulation.

It doesn’t matter what your motivation is to investigate an eco-friendly approach to your companies’ practices, the overall goal must be to work on a solution and not compound the problem.

A way forward

We are convinced that as a society, we no longer have the luxury to coordinate our activities to being just “a bit greener”, rather we must rethink our current systems and practices.

We need to not only not harm the planet, but actually have a net positive impact.

The question therefore is not “How to reduce our negative impact?” but “How substantial can our positive contribution be?”

An all-encompassing and truly holistic approach strives for a zero-waste economy and keeps materials and products in use as long as possible, minimises waste and pollution, eventually eliminating all negative environmental impacts and creating a positive ecological footprint.

Even though generating waste is almost unavoidable in industrial situations, this new thinking revolves around finding a solution to use this waste to create something else.

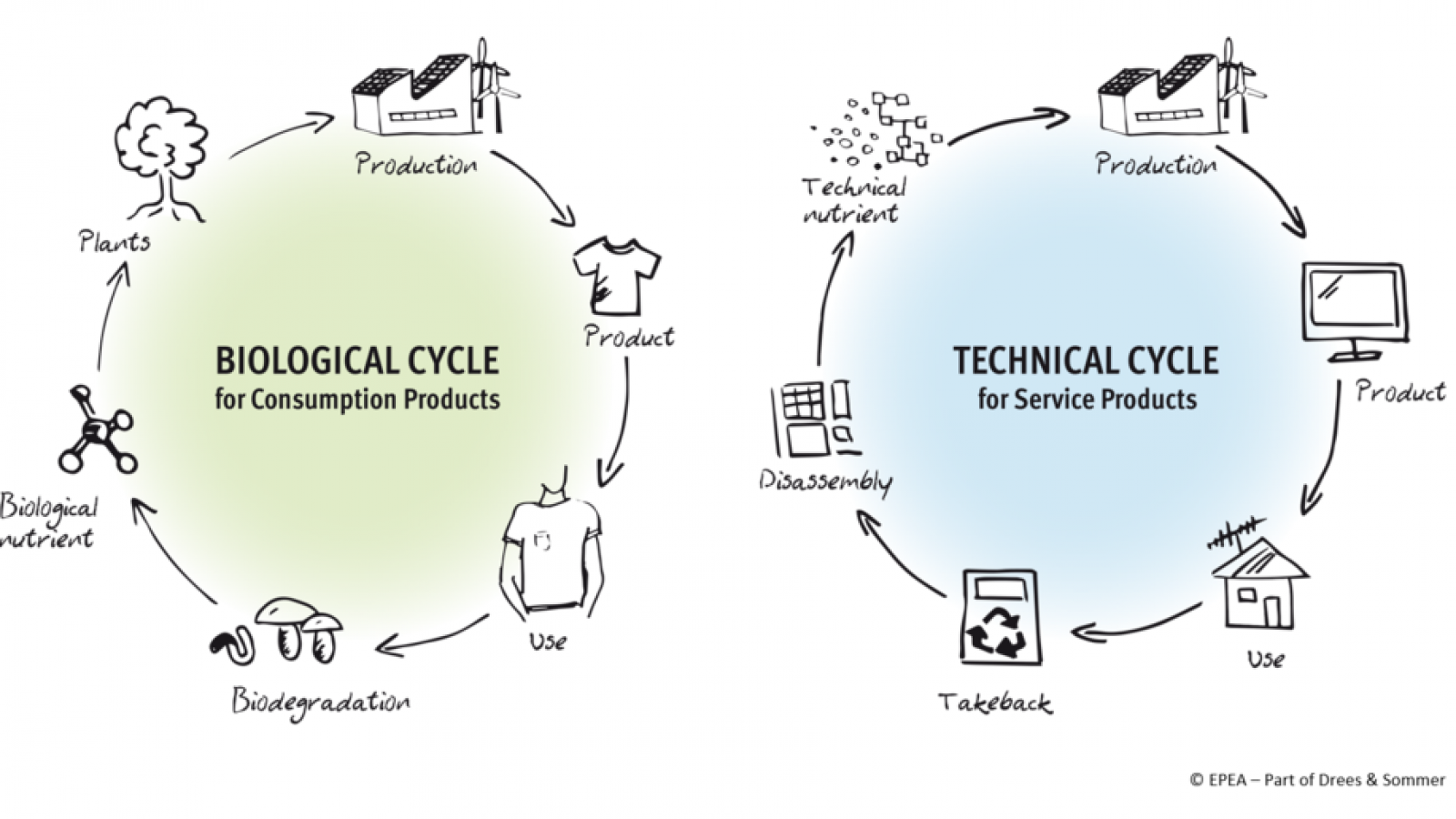

This requires our thinking to change — away form a linear towards a circular economy. Instead of the current “take, make, dispose" — from cradle to grave — mentality shift towards a circular — from cradle to cradle — philosophy.

Consequently, waste materials and energy become input for other processes through waste valorisation: either as a component or a recovered resource for another industrial process or as regenerative resources for the Earth (e.g., compost).

With this new circular approach we can:

- Turn buildings into durable and valuable material banks that release the resources again after the end of their lifespan.

- Contribute to a productivity enhancing and inspiring indoor climate.

- Create a positive ecological footprint, eg. by purifying the outside air or creating living spaces for plants and animals.

In the long-term buildings will be able to supply more energy than they consume — creating energy-positive buildings.

Conclusion

We have learned a lot from our discourse and one thing becomes strikingly obvious:

Offering a product to a customer that does not negatively impact on their health and is not harming the environment must be seen as the absolute bottom line.

We found that achieving an eco-label certification for an intumescent coating is possible. This goes to show that as long as we are truly committed to a change in our thinking and behaviour, towards more beneficial outcomes for the people and the planet, everyone can be successful.

Even if you are not striving for a certification for your product at this stage, there are so many other aspects that make it worth getting into an environmentally conscious approach for your company and see sustainability as an innovation opportunity.

We want to lead the way for a transformation towards environmental change in the passive fire industry and enable a healthy, safe, and sustainable future. But we cannot do it alone, we must build alliances with employees, communities, our customers and with other companies.

Are you with us?

Most Popular

Most Popular Popular Products

Popular Products