In recent years the residential construction sector has seen continued growth. This growth has had widespread repercussions that include both significant innovation and new challenges. As complex construction materials and technologies witness growing use, residents of multi-residential developments are demanding more services within their living space. Coupled with strong developer interest in increasing the lettable area, the question of fire compliance has become increasingly complex.

As a result, the industry now more closely scrutinises trades and subtrades, many of which are commonly falling short of compliance requirements relating to the fire rating of multi-residential apartments. This in turn extends deadlines and significantly increases project costs.

Throughout the industry, there is growing awareness of the risk of incorrect or inadequate fire separation, and builders and trades are accordingly growing more responsible and seeking innovative, effective and reliable solutions for passive fire protection.

Let’s explore the key barriers to achieving compliant fire ratings on large buildings — particularly high-rise apartments — in today’s construction climate and look at an alternative method to overcome these.

Understanding the problem

In the past, the major construction trades (being electrical, air conditioning, plumbing, data, fire, and internet) often applied their own passive fire protection after installing their services.

Whilst many builders use a Passive Specialist Applicator (a specialist trade that fire rates other trades’ penetrations) in the interests of costs and externalising risks, it’s also common for many subtrades to be accountable for the passive fire rating of their own work. This may provide a perceived shift of responsibility away from the builder, but it also poses a significant risk in terms of ensuring the adequacy of fire rating. ‘Approved’ systems can fail due to incorrect product specification or failure by the installer to follow strict installation guidelines.

Installation error is a major threat to passive fire protection since it is difficult to monitor the work methods of every subtrade. Depending on the varying skills levels of each installer, there is always a possibility that the subtrade will misinterpret installation guidelines, particularly where the fire rating system is complex or unfamiliar. Difficult installation contexts are becoming increasingly common, particularly in high-density apartments where space above the ceiling is at a premium.

As a consequence of developers seeking to maximise lettable area, the ceiling space height in multi-residential developments is often decreasing, while the complexity of technical services into each apartment is increasing — thereby further complicating the whole firestopping challenge. Without destructive inspections, it’s difficult to identify a passive detail after installation as physical aspects are not visible.

In addition to physical complications, the number of materials that must be protected within the tight confines of today’s multi-residential apartments is increasing. Residents now expect more services than ever in their living spaces, many of which use multiple cables and pipes, and trades must now engage with the latest in pipe material innovation and the myriad of plastics used for different pipe applications (such as PEX, PEX-AL, PP, PP-R, HDPE, uPVC, cPVC, and more) as well as mechanical bundles that include paircoil, cables, and lagged or unlagged metal pipes.

When it comes to cable types, the possibilities feel endless, and the ‘Standard Configuration’ becomes hard to work to when all the possible variables, sizes and quantities are considered.

Unfortunately, the vast majority of fire rating technology available does little to simplify the product selection process, and the impracticality of understanding all tested systems on the market makes it difficult correctly install one hundred percent of the time.

How the industry has responded

Growing concerns regarding fire safety have also prompted a general movement in the industry toward investigating new, innovative fire rating technologies. In conjunction with the rising popularity of multi-residential apartments, these concerns mean that industry now seeks solutions that can bundle multiple services in tight spaces and at the same time reduce the risk of installation error.

In short, the industry needs fire rating solutions that ensure compliance, reduce cost, and eliminate the risks.

Innovative tested solutions

In response to growing demand for fire rating technologies that overcome the challenges typically associated with passive installation, BOSS Passive Fire developed the BOSS Fire Transit Box which provides a new method for firestopping services into apartments and units in residential buildings.

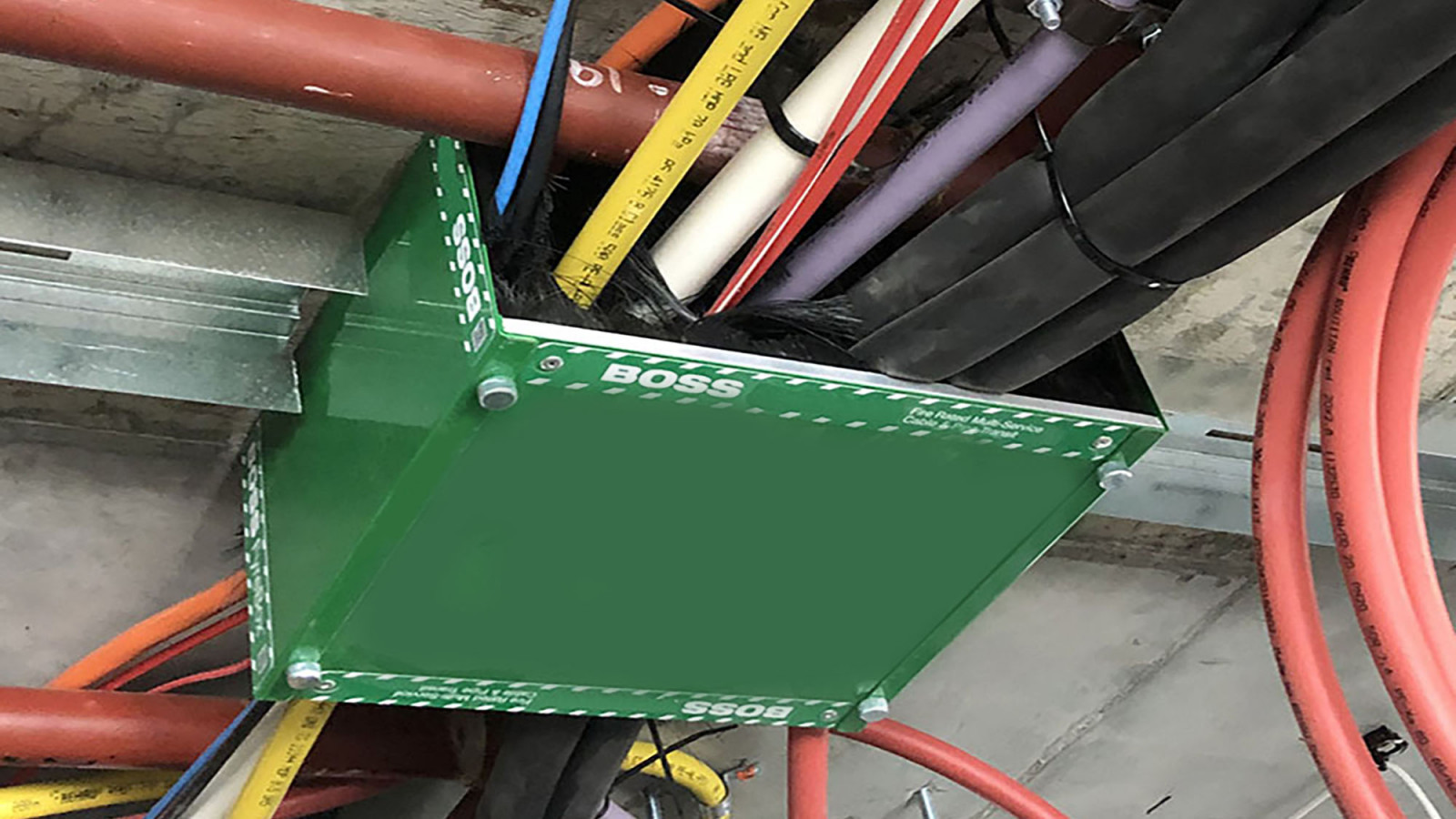

The benefit of a fire transit box is that it “bundles” services into a single solution, so there’s no need to individually treat pipes and cables with traditional sealants, wraps, collars and backing rods. Use of a multi-service pipe and cable transit lowers overall build cost, simplifies the installation process and eliminates risk involved with other life safety passive fire practices to achieve building compliance.

In the case of the BOSS Fire Transit Box, which comprises a steel chassis, HPE expanding intumescent and an innovative BrushSeal that allows trades to simply “pass through” pipes and cables in one small compact product, building code compliance is met including AS1530.4:2014 and AS4072.1-2005 with an FRR of up to -/120/120 on the widest range of services. In most applications, there is no need for any additional thermal wrap, as the system meets all the requirements of AS1530.4, AS4072.1 and the NZBC.

Multi-service transit boxes can be installed before any walls are constructed — often fixed into place by the first trade onto a newly formed floor, such as the dry wall partition installer or fire sprinkler contractor. This makes scheduling a breeze, removing the traditional requirements that dictate the order of process amongst trades. Independent contractor assessments estimate that use of a multi-service transit such as the BOSS Fire Transit Box reduces up to 90% of labour costs compared to traditional methods, and significantly reduces overall build time and cost.

Beyond this, use of a fire transit box eliminates the scope for error. Services trades simply slide their pipes and cables through the box and get on with what they do best — their trade. The mounting method for services is exactly the same as that for a non-rated wall, and removes the possibility of installation error due to poor workmanship, incorrect product selection, or misunderstood instructions. Where other methods of passive fire protection are accompanied by complex or hard to interpret instructions, the straightforward installation of multi-service transit boxes leaves little room for mistake.

This single, streamlined product ensures compliance at the time of installation meaning project sign-off its simple and transparent. And with periodic checks made just as easy, the ongoing inspection requirements of AS1851 (Maintenance of Fire Protection Systems and Equipment) are significantly streamlined.

Most Popular

Most Popular Popular Products

Popular Products