In last month's blog post, I discussed the different types of glass used in construction. As I continue this series on structural glass, this month I want to discuss the properties and behaviour of standard structural and laminated glass and the different factors that can cause glass failure.

Properties of glass

Glass density is similar to concrete’s density of 2500kg/m³.

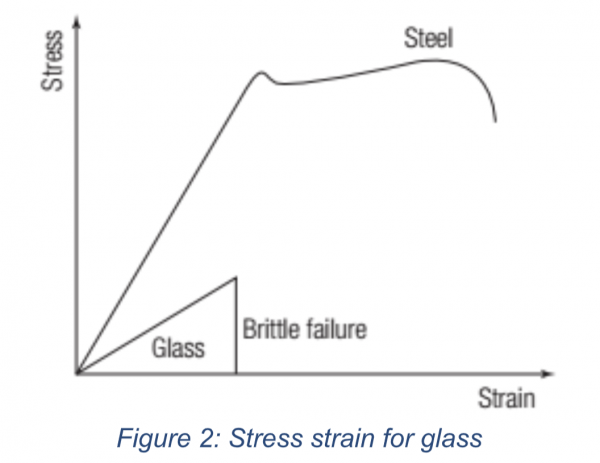

The modulus of elasticity of glass is 70MPa — about a third that of steel, and glass behaves linearly elastic until sudden “brittle” failure. As glass is a brittle material with the inability to resist crack propagation, it does not strain physically and cannot dissipate imposed stress, such as temperature shock. The compressive capacity of glass is estimated to be approximately twenty times that of its tension capacity.

To avoid stress concentration points, the designer must prevent any direct contact between glass and glass, or between glass and rigid structure (eg metal, concrete, etc). To avoid contact between such materials, appropriate separating materials should be used, such as elastomers and thermoplastics in accordance to DIN18008.

Glass is a non-combustible material and does not contribute to the building's fire load. However, glass will transmit heat and under certain temperatures can crack and break down — both characteristics could result in the continued growth of a present fire.

Glass strength is time-dependent. The linear behaviour of glass until its fracture shows that it does not experience fatigue, but Sedlacek (1) has shown that the strength of glass is time-dependent. Glass can carry more load for a short period than for a long period of time. This is what is called the fatigue of glass.

Analysing the behaviour of glass

When glass is subjected to small deflections, the stresses are predominantly due to bending and linear analysis is adequate to reflect the structural behaviour of the glass.

When the deflection is greater than the thickness, the membrane action (where stresses along a plane are predominantly in tension) becomes essential and could be dominant over the bending action. Because linear analysis overestimates the stress in the plane, a nonlinear analysis using finite element method would give a more accurate result.

Glass behaves as an elastic material. This means that the theory of elasticity is directly applicable for determining stress and strain. Typically for structural units of glass plates, the thickness is small compared to the in-plane dimensions. This may result in structural complication when a glass plate is loaded perpendicular to its plane, as there will be both bending and membrane responses.

All finite element results should be double-checked using simple analytical methods. A very good fit between numerical and analytical results can be expected.

Analysing the behaviour of laminated glass

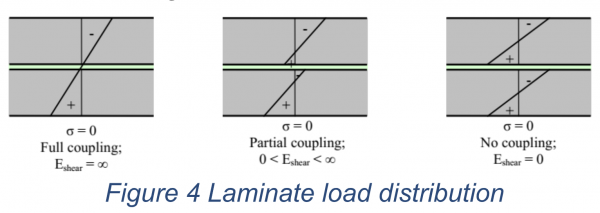

The behaviour of laminated glass is complex due to the behaviour of the interlayer which is variable according to load duration, material and temperature, and affects the load distribution between the glass layers in the laminate. Additionally, the use of different interlayers, types of glass, as well as variable plane thicknesses are other factors which make it difficult to determine the properties of laminated glass.

One of the potentially beneficial characteristics of Laminated Glass is that it is likely to remain intact upon breakage. The glass adheres to the interlayer which prevents fallout and resists penetration. This offers superior safety.

Edge delamination (interlayer bond losing its strength to hold glass planes together) is possible in all laminated glass products and is usually the result of interlayer breakdown by atmospheric moisture or degradation from contact with incompatible products. Exposing edges to moist and humid conditions can accelerate delamination, so it is recommended that edges be fully glazed and sealed wherever possible. The general rule of thumb is that edge delamination should not exceed 6mm from the edge.

Figure 5: Delamination effect (source ref 2)

Analysis of IGU

The primary functions of IGU’s are to provide thermal insulation for building envelopes. In colder climates, Insulated Glass Units are designed to reduce heat loss and allow some solar heat gain, whereas in warmer climates they are to reduce indirect air to air transfer from outside to inside. IGU's are also effective means of controlling solar heat gain through a suitable selection of glass such as tinted and/or coated glass.

In next month's blog post, I'll be discussing how to select the right structural glass for different applications.

Written by Khaled Eid

Engineering Manager

Metro Performance Glass, Auckland

References:

- The institution of structural engineers. Structural use of glass in buildings (Second edition) Sedlacek, G & Blank, K & Guesgen, J. (1995). Glass in structural engineering. Structural engineer London

- Edge Stability, Durability and Weathering, Curbell Plastics

Most Popular

Most Popular Popular Products

Popular Products