With most building systems, failure is often likely at the interface with another system. With Below Grade Tanking (BGT) systems the risk of failure is exponentially higher. In the event of a failure, a remedy is either extremely expensive or may even prove to be impossible.

The common saying “You only get one chance to get it right” is true for most BGT projects.

Where a BGT system connects with a Damp Proof Membrane (DPM) is a detail that many designers have drawn without fully understanding how these dissimilar membranes are connected.

For context, imagine where a DPM (in most instances Polythene) is installed into a footing. The chances of it being exposed and clean, and free of punctures and splits is unlikely. Add in the winter weather (and all that mud inside a footing) and the chances of achieving the goal of a 100% watertight tanking system will be slim.

In reality, there are no membranes that can achieve this connection without some risk of failure. The WMAI has developed a solution that is accepted by all of its members as the only way to best achieve this common detail.

It is a simple solution to execute but relies on the site foreman’s understanding and the correct sequencing. Note, the below solution does not apply to Bentonite systems.

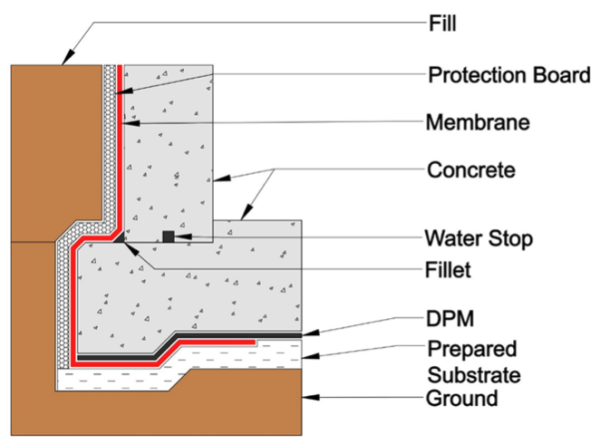

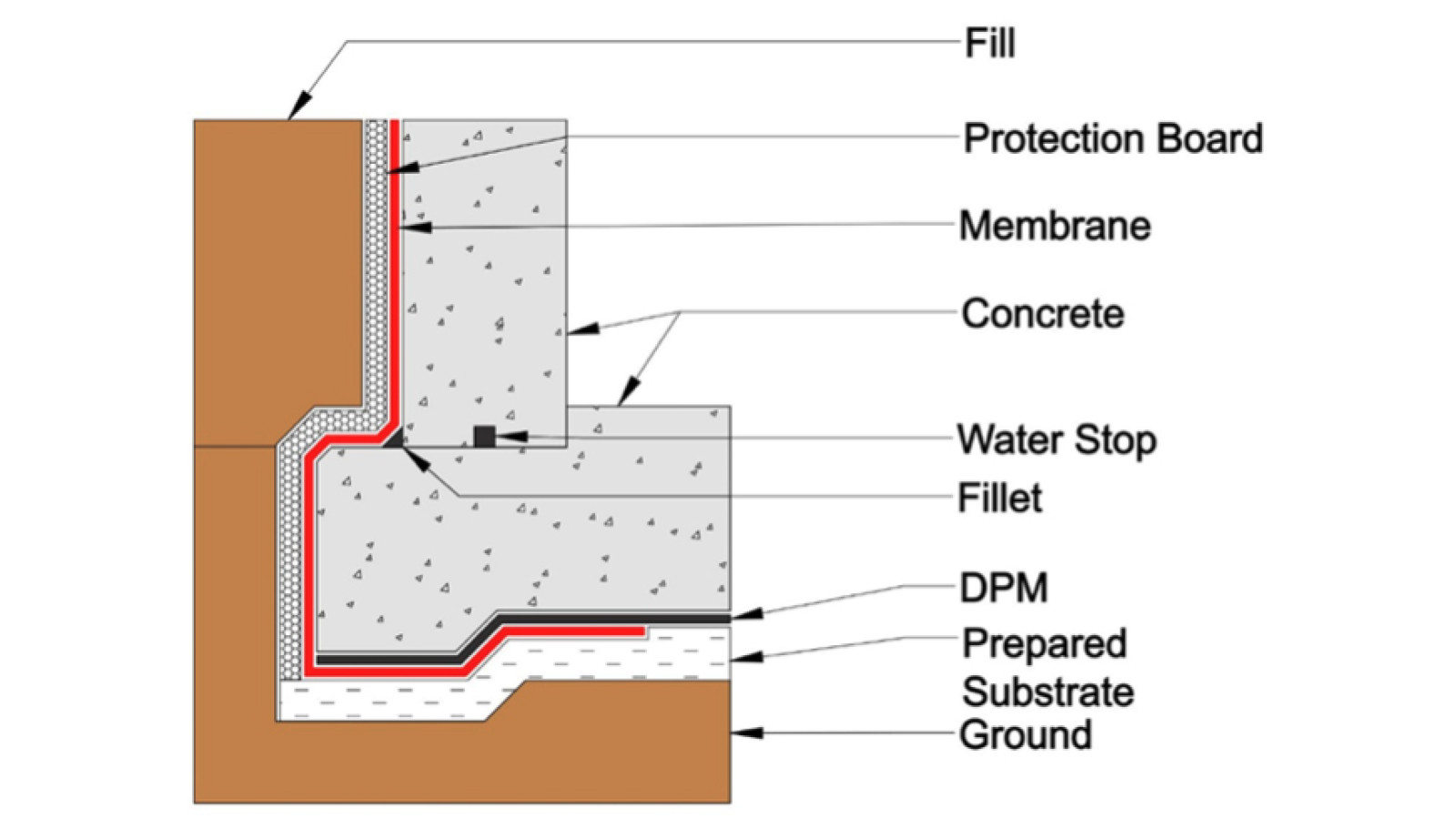

Fig 1. Footing with BGT membrane to DPM, 300mm minimum lap.

The membrane is installed under the footing with a 300mm lap to allow for the DPM to be lapped over the membrane. The weight of the concrete will achieve a tight seal which will allow the system to resist rising damp.

Should there be any chance of a rising water table or the inability for the water to quickly drain away, then the entire footing and under slab must be fully tanked.

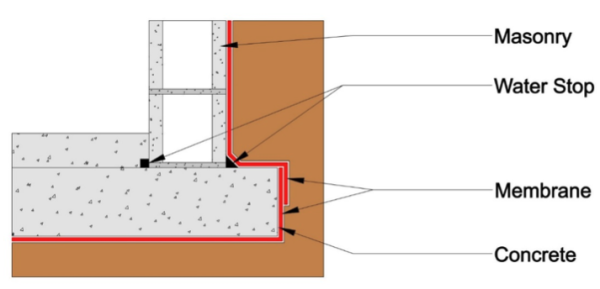

Fig 2. Footing for areas of poor drainage and/or hydrostatic pressure and for all Bentonite systems.

Bentonite tanking systems work differently to other membrane systems in that they rely on water to activate the Bentonite clay that is encapsulated within the fabric. The system is confined by the back fill. When moisture contacts the Bentonite, it swells and expands into all crevasses with such pressure that the water can no longer pass.

If water can migrate between the Polythene and the footing and not activate the bentonite there is a chance that water may get into the under-slab of the system.

For this reason, Bentonite systems should only be installed as described above.

Note all drawings are representative only. All suppliers will have specific product details.

The full copy of the “Below Ground Tanking Code of Practice” (BGT) is available from the Waterproofing Membrane Association Incorporated website: www.wmai.org.nz

Most Popular

Most Popular Popular Products

Popular Products