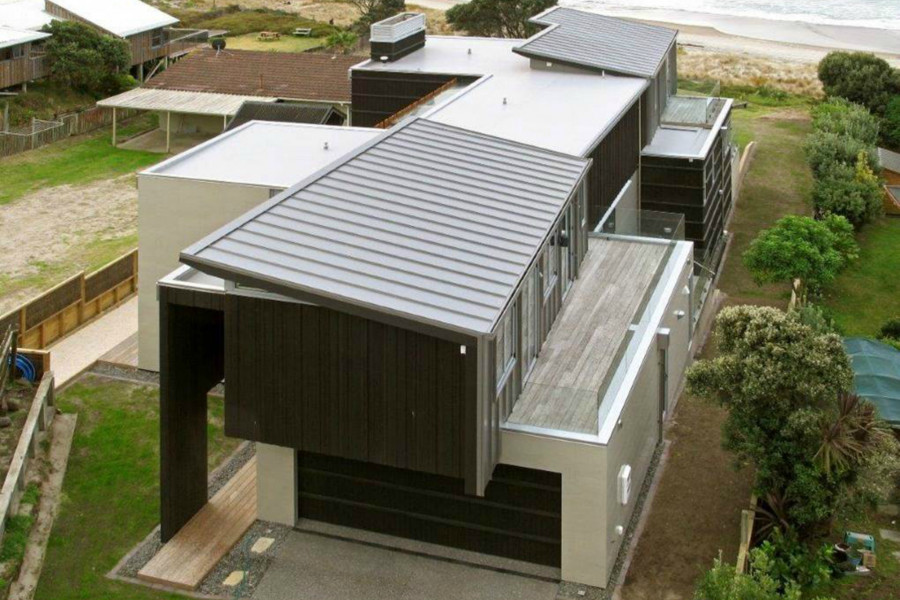

The redevelopment of the 45-year-old science precinct building at the University of Otago has finally come to a close after three years. The 50 million-dollar revamp included a new exterior design, recladding, and a new roof system with detailing complexity that would send the faint-hearted running a mile.

Using clause E2/AS1 of the Building Code as a benchmark, the architect specified that the dead flat (zero-degree) concrete slab roof substrate be clad with a roofing system sloped to a minimum of two degrees. The roofing system needed to be robust and possess the design flexibility to successfully waterproof the 200-plus penetrations of various sizes made by the significant extraction systems used to ventilate the faculty’s precious equipment. Alternative cementitious screed systems were considered for creating the required falls, but they would have been too heavy and were considered less practical in terms of the application required in these circumstances.

Viking Roofspec’s WarmRoof system provided the University of Otago with a fully-tapered polyiso insulated sheet scheme, specifically ‘shaped’ for this 1400m² roof using Kingspan’s custom-tapered service from the UK.

Viking Enviroclad’s heat-weldable accessory range, with particular reference to its pipe seals and other penetration sealing system called ‘pourable pockets’, made Enviroclad the obvious membrane choice for the needs of this challenging roof. An added bonus is that Viking Enviroclad’s puncture resistance protected the polyiso sheets from the unavoidable large amount of foot traffic from other trades during construction.

One of the key reasons behind the success of this project was the skill and professionalism of the Approved Applicator Company installing the tapered warm roof system. Construction materials only look and perform as well as their installation. As a materials supplier, Viking Roofspec aligns itself with the industry’s best contractors while having invested heavily in its three-staged licensing programme to ensure its materials are installed with pride and to specification.

Additionally, to ensure the success of this complex tax-payer funded job, the communication required between the multitudes of stakeholders needed to be frequent, technically correct, efficient and positive. Stakeholders included the University procurement staff, the architect, the construction company, project managers, council, shipping lines, storage companies, Kingspan NZ, Kingspan UK, the Approved Applicator and Viking Roofspec. The finished result would indicate that this was achieved.

Case Studies

Case Studies

Popular Products from Viking Roofspec

Popular Products from Viking Roofspec

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts