This is certainly a topical question and an important one at that. Ventüer spent some time crunching the numbers and while they're not sharing them here, not yet anyway (they want them to be independently verified first) they did want to talk about carbon in aluminium in general.

Why? Because there are some important differences we feel do need highlighting because it's possible to make an informed choice when it comes to specifying aluminium louvres. That’s because not all aluminium is the same, and knowing where the aluminium in your louvres comes from can have a big impact on the planet, and the sustainability credentials of your building.

Black aluminium vs green aluminium

The bond between aluminium and oxygen is especially strong, much stronger than that between steel and oxygen. Accordingly, a lot of energy is required to split the bond to form the metal. In fact, 211 GJ per tonne is needed.

This makes the smelting process of aluminium electricity-hungry, and it’s the source of that electricity that makes the aluminium you specify either good or bad (relatively speaking). At the bad end of the scale is what’s known as Black Aluminium. This is so-called because the smelting process for this aluminium relies on electricity derived from the burning of fossil fuels.

At the good end of the scale is Green Aluminium. Here, the smelting process relies on electricity sourced from hydropower. The Tiwai Point smelter is a good example of this, and is widely recognised as producing green aluminium with arguably the lowest carbon footprint in the world.

The difference in the cradle-to-gate emissions (t C02e) between black and green aluminium is significant. A report by the Energy Research Consultants at Wood MacKenzie, highlights this difference, showing that where aluminium is produced in a smelter such as Tiwai, the emissions are typically around ⅓ of those from smelters powered by coal.

There are some outliers to the typical variance and at the extreme end of the scale is black aluminium sourced from China. The cradle-to-gate emissions from aluminium produced in China are up to 5 times higher than the green aluminium made locally in New Zealand. In fact, the pollution from aluminium smelting in China is so bad that a London based think-tank concluded that the collective emissions from China’s aluminium production emitted more greenhouse gases than Indonesia. For reference, Indonesia is the 8th largest emitter of greenhouse gases in the world.

It can be hard to conceptualise just how big the difference between aluminium made in New Zealand and China is, so here’s another way to look at it. One tonne of aluminium smelted in New Zealand will produce about the same emissions as three return plane trips from New York to London. One tonne of aluminium smelted in China will produce about the same emissions as 15 return plane trips from New York to London.

This difference is affecting demand and Tiwai, despite the uncertainty about its future, recently signed an agreement with a large Japanese trading house for low C02 aluminium. That aluminium is destined for a motorcycle manufacturer who wanted the product from New Zealand because it’s widely acknowledged as some of the cleanest in the world. A fact they can use in their marketing, offering a point of difference for their products.

The Carbon Cost of Aluminium Transportation

Aside from the carbon cost associated with the actual production of the aluminium itself, there’s the cost to transport it. Shipping might appear to be a ‘green option’ for transport, and in many regards it is, but the fact remains that even a relatively low carbon transportation method adds up when it's needed to ship aluminium all over the globe. The maritime industry accounts for up to 4% of all climate change emissions and the World Bank says this makes shipping the 6th largest greenhouse gas emitter in the world, ranking just behind Germany.

This means that black aluminium not only has a large carbon footprint to begin with, but it gets bigger every step it takes to transport it from the smelter to its end destination. If that end destination is New Zealand, the footprint is certainly significant enough to be of concern.

Where Ventüer aluminium comes from

Ventüer has taken steps to make sure our aluminium ends up on your building with the lowest possible carbon footprint. They source only green aluminium from Tiwai. That might change in the future of course, given the question mark hanging over Tiwai’s future, but for now it means their green aluminium is as clean as it can be. As Tiwai is also local to Ventüer (especially our manufacturing base in Invercargill) it means they've also dramatically reduced the Carbon cost of the distribution chain.

In simpler terms, when you specify Ventüer louvres you can be assured the aluminium comes with the smallest carbon footprint possible.

Circling back to the start of this article, this becomes important because not all aluminium louvres on the market in New Zealand use green aluminium. Many use black aluminium sourced from China.

We should note, as soon as we have a reliable method for calculating the carbon in our louvres, we’ll publish that data. For now, all we can say is we know that, comparatively speaking, Ventüer louvres carry a significantly lower carbon footprint than most. If your project build has a sustainability focus, it makes Ventüer the best choice.

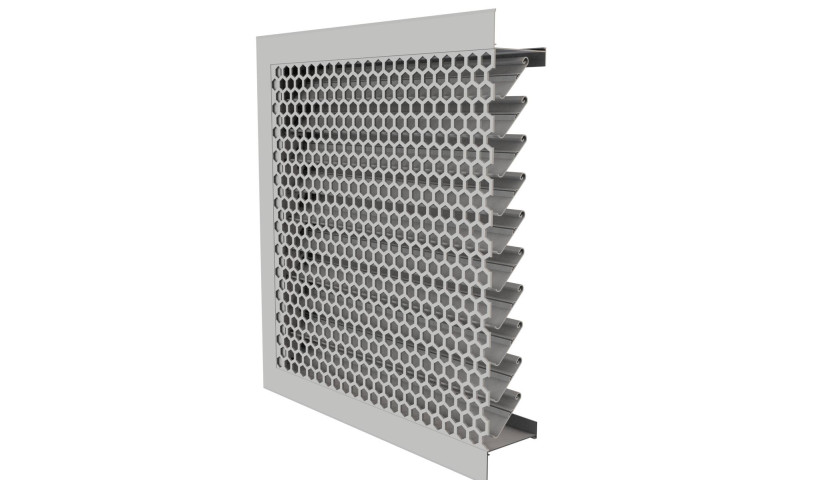

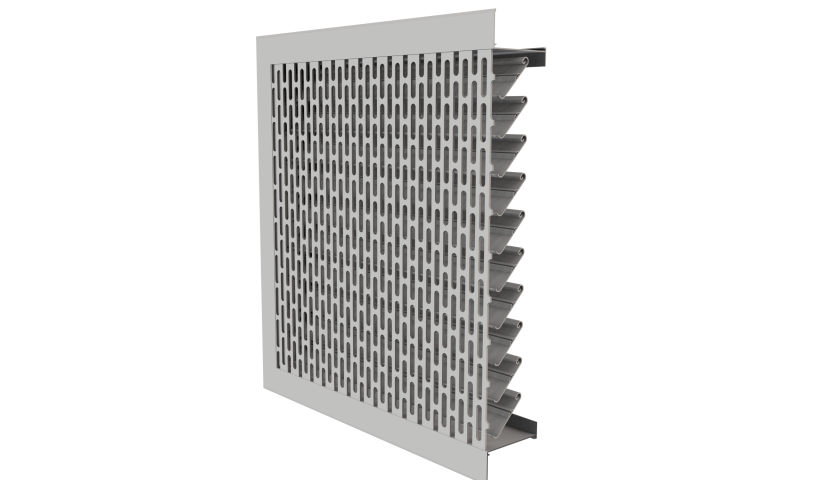

Of course, we do happen to think the louvre design themselves makes them a good choice too…

New Products

New Products

Popular Products from Ventüer

Popular Products from Ventüer

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts