With large expanses of glazing on The Cascata and extreme temperatures in Queenstown, it is clear that the passive house certified TGI-M spacer for double and triple glazing was the ideal solution for protecting the edge of glass from condensation and heat loss.

The impressive floor to ceiling windows and incredible 90% window to wall ratio overlooking the beautiful Queenstown lakes are truly a sight to behold. As windows are often the thermal wound in the building envelope it was crucial that the window system installed in The Cascata achieved the highest possible thermal rating.

When specifying warm, dry and healthy windows it is important to remember that in a cold climate heat is always trying to escape through the path of least resistance. In a window system heat is escaping through multiple components such as the:

- Glazing

- Window frame

- Double glazing spacer bar

- Window installation

The minimum R-value requirement for windows in New Zealand is 0.26m2K/W. This is assumed to be a window system constructed with an aluminium frame, standard clear double glazing with aluminium spacers. In this scenario, the aluminium frame is the path of least resistance as it forms a thermal bridge between the internal and external surfaces of the building and greatly increases the risk of condensation.

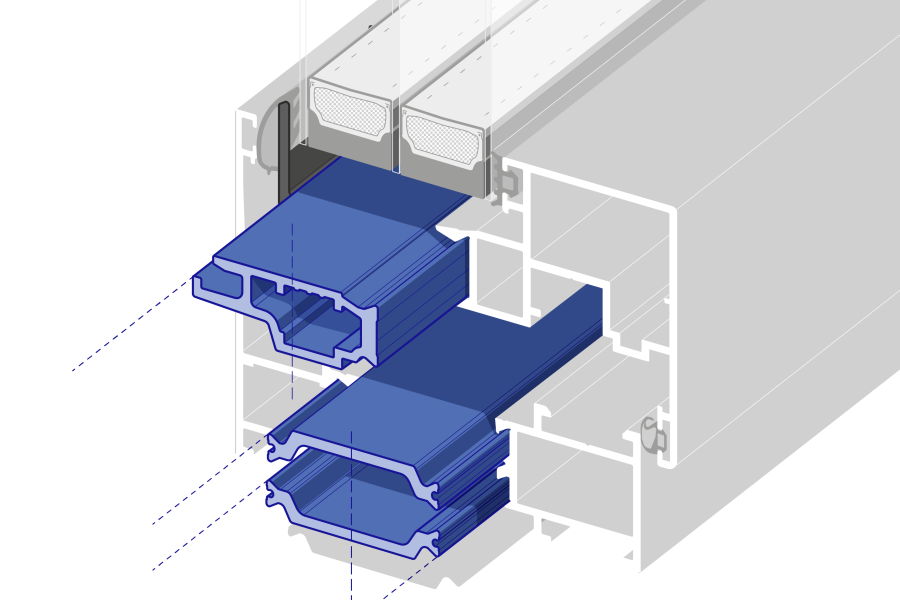

Due to the large area of glass, The Cascata was specified using not only Thermally Broken aluminium frames (thermal breaks supplied by Technoform) but also high-performance triple glazing with special Low-e coatings and filled with argon gas.

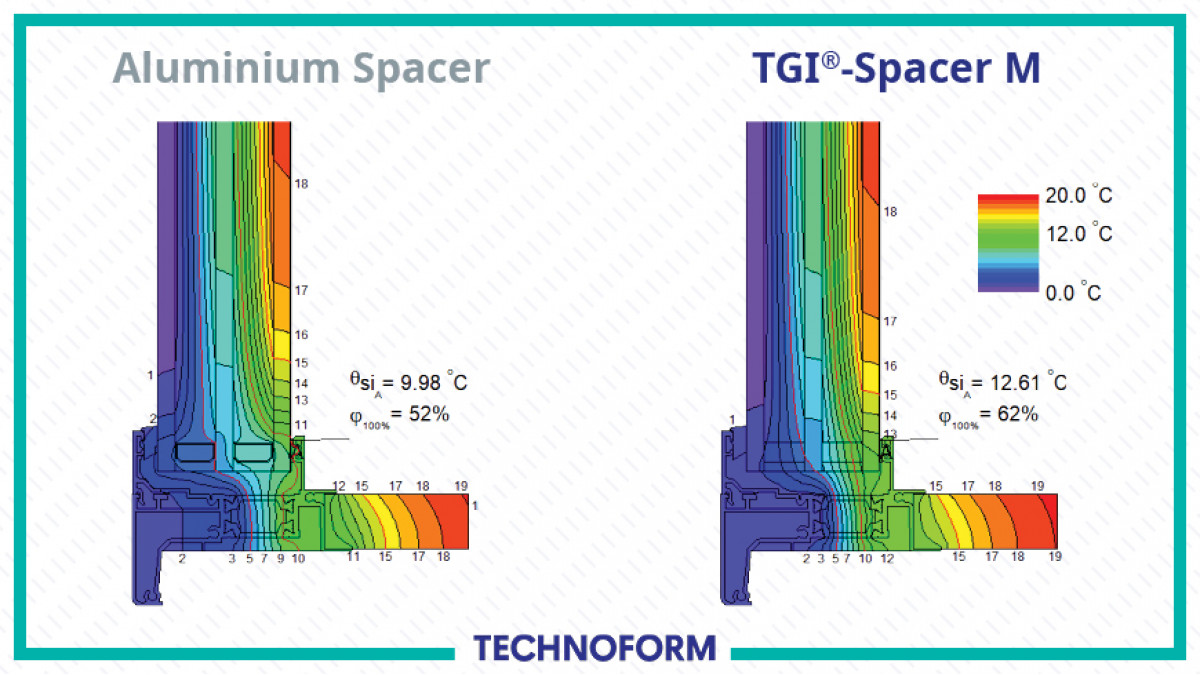

In this scenario, the aluminium spacers would now provide the path of least resistance for heat to escape and would encourage condensation to form around the visible edge of the glass.

However, The Cascata has avoided this thermal bridge by specifying a warm edge spacer that is used to separate the three panes of glass. In this case, Technoform’s TGI-M warm edge spacer was used throughout the project and was supplied by Viridian Glass Nelson.

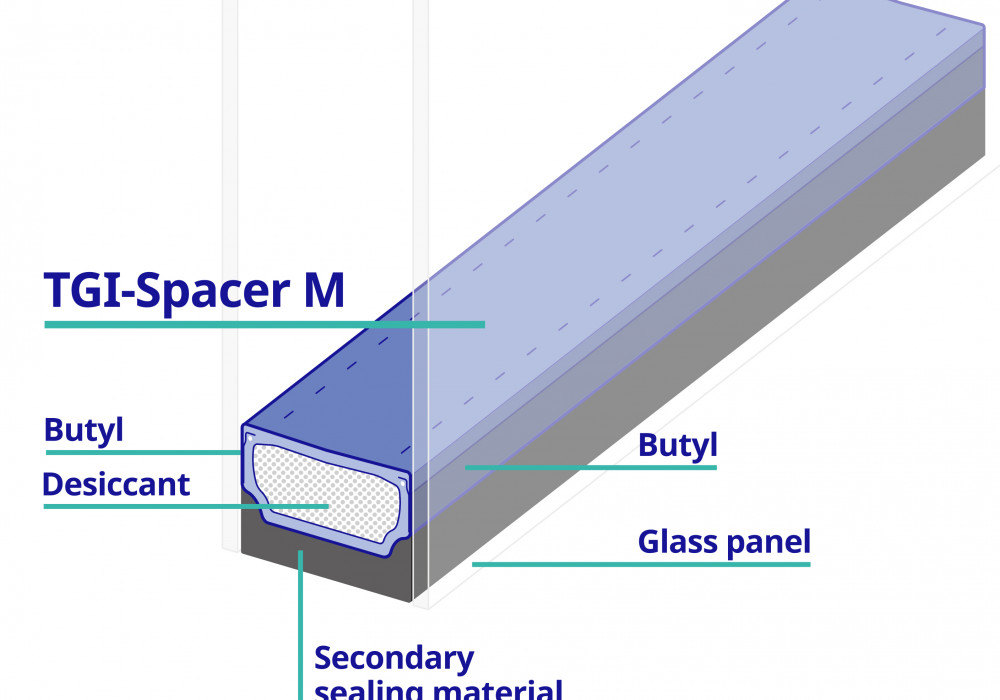

The TGI-M spacer is a hybrid warm edge spacer product constructed of co-extruded polypropylene and stainless steel. It is defined as a “warm edge” spacer as it is keeping the edge of glass warm and free of condensation. The TGI-M product is passive house certified and provides a thermal barrier preventing heat loss through the edge of glass.

In high-performance windows, the TGI-M spacer can increase thermal performance of the window by 10% and increase the edge of glass temperature by 2.6°C.

Project Window thermal performance:

- Triple Glazing: R 1.5 – 1.8m2K/W

- Thermally Broken frame: R 0.35 – 0.50m2K/W

- TGI Spacer: 0.041 W/mK

Product News

Product News

Popular Products from Technoform

Popular Products from Technoform

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts