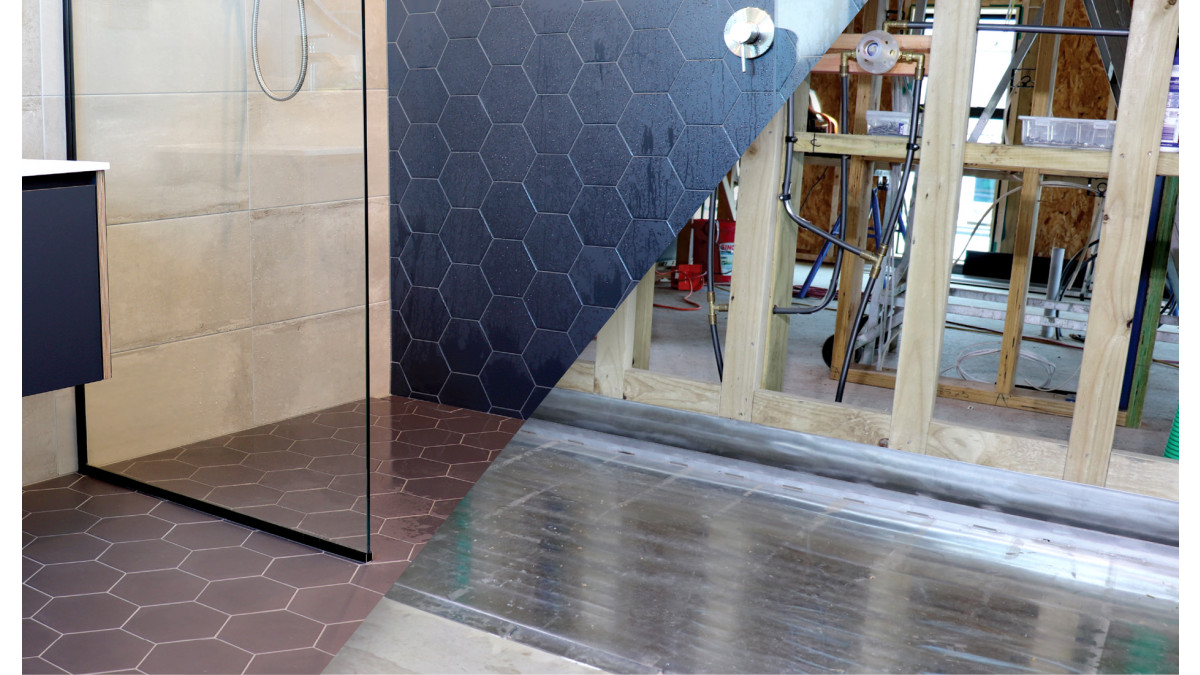

Modern building design places an emphasis on maximising usable space in smaller footprints, therefore design features such as open-concept bathrooms have become popular to extract maximum value from the space available. By removing a boxed in shower unit in exchange for a tiled shower, the space can become drastically more usable.

There are certain aspects to AS/NZS standards and the NZBC E3 that must be accommodated for during the design and install of a tiled shower. Ensuring that water is retained within the designated shower area is important, this will predominantly be controlled with the combination of walls, doors and fall in the floor towards an outlet.

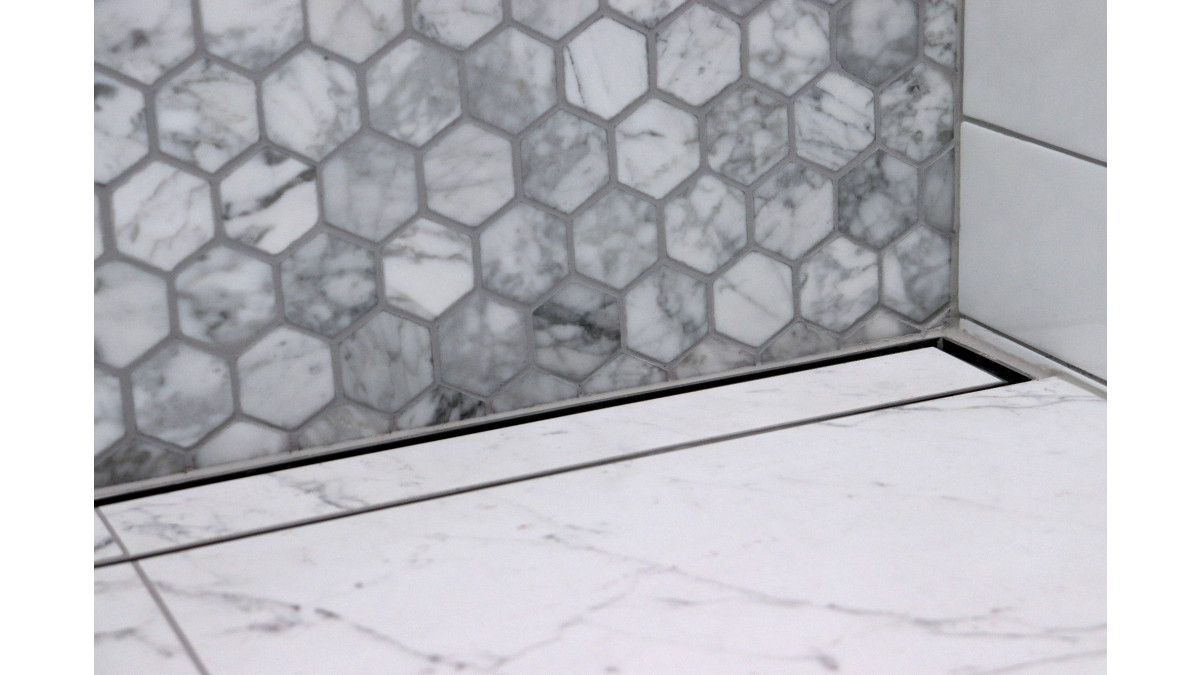

Most residential showers will be considered a ‘Type 1’ (according to AS 3740-2010; 3.13.5) with a frameless glass screen, shower curtain and/or waterstop hob entry controlling splash and surface water. Therefore, a minimum of 1:100 fall is required where a hob is present. A minimum of 1:80 fall is needed for all other shower areas. By designing a shower with a channel drain (typically running along the back wall under the showerhead), the installer will only need to screed a fall in one direction, this then improves the aesthetic finish and reduces the amount of work conducted by the tiler by avoiding crosscuts through the tiles towards a central point drain outlet. AS 3740 states “it is advisable to have either the screed drained or a membrane placed on the top of the screed to prevent retention in the screed beyond the water stop.”

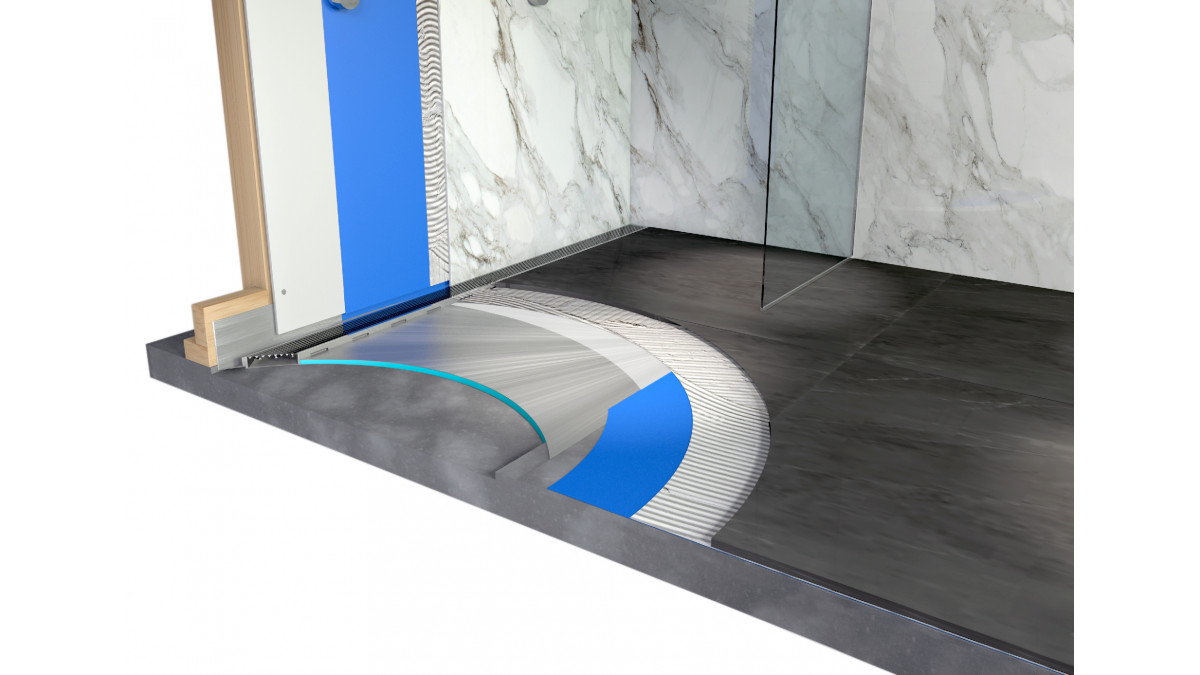

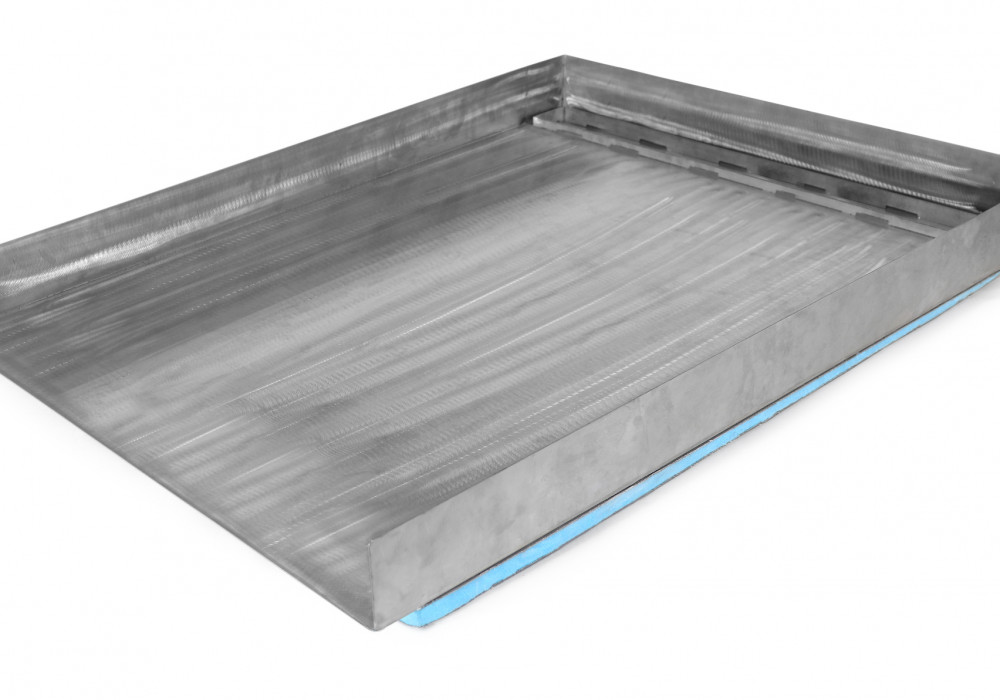

New Zealand’s wide offering of waterproof membranes combined with Allproof’s drainage systems such as the Vision Shower Channel creates some excellent options to protect the structure of the building from moisture created within this area. For those who prefer the assurance of a shower tray/base being present, especially in bathrooms located in timber structures or multi-storey buildings, an Allproof stainless steel shower tray can be installed under the tiles creating an impermeable barrier directly under the wet area.

A tile over stainless shower tray would also be considered a “Preformed Shower Base” (AS 3740-2010; 3.6) needing to be sufficiently recessed into the wall and floor allowing waterproof membranes to be dressed onto the flange surface areas (textured to maximise bonding), it should also be supported to prevent distortion or cracking. Allproof have designed the tray to incorporate the fall outlined for Type 1 showers by utilising an engineered base. The tile over stainless tray provides options of a 1:80 (recommended for hob entry) or 1:50 (recommended for level entry) fall which satisfies NZBC E3 3.3.5 which looks to obtain a fall of 1:50 towards the shower drain. The tray has a channel drain built into the system with tile bar options designed to suit varying tile depths and weepage holes allowing subsurface moisture trapped by the stainless tray to track into the waste outlet.

The Allproof preformed Tile over tray system makes tiled showers easy while providing peace of mind for installers by creating a system that accounts for the required falls, provides a reliable impermeable base, removes the need to screed, allows for direct stick tiles and flat floor framing. Tile Over Stainless Trays are custom made in New Zealand to project-specific measurements, a custom quote/order form can be downloaded from allproof.co.nz.

Product News

Product News

Popular Products from Allproof Industries

Popular Products from Allproof Industries

Posts by Andrew Smith

Posts by Andrew Smith

Most Popular

Most Popular